Even before the onset of the first frosts, many fans of winter and ice fishing, both with impressive experience and those just starting out, are wondering about purchasing a convenient and high-quality ice auger. After all, without this tool, fishing in winter is unthinkable.

What to consider when choosing it:

- Firstly, this is the diameter of the auger, the main part with which the hole is drilled. It all depends on what kind of fish you plan to catch. For medium-sized fish, roach, perch, small pike, an auger with a diameter of 90-100 mm is suitable. For fish such as white bream, bream, large pike and pike perch, we choose an auger of 120 mm or more.

- Secondly, there must be a reliable connecting node (elbow). When purchasing, you should check the possibility of future play in assembled, working condition.

- Thirdly, the direction of rotation of the ice drill, clockwise or counterclockwise. This is a matter of habit or convenience for each person.

Be sure to visually determine the quality of the weld at the junction of the auger with the tubular part of the ice auger, in order to check for poor quality workmanship. Otherwise, the auger with knives may remain in the ice when drilling.

The quality of the paint used to process the instrument is also important. If it peels off quickly, then the adhered snow and icing will complicate the process.

And the most important thing is the quality of the tool’s knives. When purchasing, it is worth inspecting the working (cutting) part for thermal lines, which indicates non-compliance with maintaining the temperature regime during factory sharpening. Such steel is already considered unsuitable for use for drilling holes in ice.

How does an ice screw work?

An ice ax for winter fishing is a tool consisting of three parts:

- handles;

- several cutting parts;

- auger

The principle of operation of an ice ax is identical to a rotator. The fisherman turns the handle and the sharp parts bite into the ice.

Some fishermen install a gasoline engine on an ice ax. This tool allows you to cut ice faster, using less effort. It is relevant in cases where the ice is thicker than 1 meter.

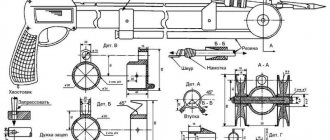

Sharpening drill knives - leveling the circle

To sharpen the knives of an auger ice drill with straight cutting edges for the upcoming winter fishing, an abrasive fine-grained wheel with smooth side planes is suitable, one of which will be the working surface when sharpening knives.

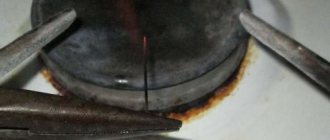

But since abrasive wheels wear out unevenly during work, before the next sharpening of knives for an auger ice auger, we should align one of the side planes of the abrasive wheel or block.

To do this, another abrasive wheel is applied to the leveled surface and the lateral planes of both circles are rubbed against each other using rotational movements.

The result: after some time, you get two absolutely flat (or slightly convex) surfaces on two abrasive wheels. Next, the cutting edges of the auger ice drill knives are sharpened from the bevel side.

The sharpening process requires some skill and accuracy. I consider the edges of the knives of an auger ice drill on an abrasive wheel to be sharpened if microscopic burrs form along the entire length of the beveled planes on the back side of the knife (on a wide plane). I don't take them off.

The angle of entry of the knives into the ice on my most popular auger ice drill is such that it is better not to do this. But, if the knives on your ice drill, after grinding them, simply begin to bite into the ice, then it is better to remove the burrs from the wide surfaces of the knives.

It is better to fine-tune the working surfaces of the auger ice drill knives on the wet surface of the abrasive wheel.

Knife types

Types of ice ax knives:

- flat blades - have straight sharp parts;

- stepped blades - has two cutting parts;

- serrated cutting edges;

- triangular blades - suitable for cutting melting, loose ice.

Each type of sharp edge is suitable for different types of ice, since there are no universal tools. For example, straight ones are easier to cut dry ice on cold days, while stepped ones are easier to cut through strong ice cover.

Serrated cutting edges (Photo: Instagram / vyacheslavbrodnikov)

Sharpening Tools

To sharpen knives with your own hands, you need to buy in advance a special device for holding one corner and other tools:

- A special sharpener. In a store that sells ice axes, you can ask about similar tools and instructions on how to use them.

- Abrasive bars. It is necessary to purchase carborundum stones of different grain sizes in advance. It should have wide working surfaces. When sharpening, you should constantly wet the surfaces of the stones. You need to start with a large grit and end with a fine one.

- Sandpaper. It is suitable for correcting minor irregularities and bringing the blade to working condition. To repair gross damage, you can use coarse sandpaper. After sanding, scratches will remain on metal surfaces. They are removed with felt.

- GOI paste, glass. The simplest options for sharpening blades. If using a glass jar, you need to run the blade over its surface several times to restore sharpness. You can use glass bottles instead of jars. The blade must be drawn along the end of the neck. Using GOI paste you can give the metal a characteristic shine and make the surfaces mirror-like.

Resharpening cutting edges with an abrasive stone:

- Place the block on a rubber plate so that it does not slide to the side during use.

- For additional fastening, you can use tape.

- Remove rough burrs and chips with a file.

- Turn the part over with the cutting part facing the abrasive stone and set the angle. To do this, it is more convenient to cut the cardboard at an angle of 30 degrees in advance. Perform even circular movements with gentle pressure.

When regrinding, you need to constantly check how accurately the edge is processed along its length. After carrying out the work, you need to run the blade over the paper to check its sharpness.

Craftsmen use grinders and grinders for sharpening, but these tools are dangerous for beginners and require practical skills.

Sharpening tool (Photo: Instagram / studiosharp.ru)

Bevels of ice drill blades

The landing pads of the auger ice drill knives have two bevels. In relation to the axis of rotation they must be identical, but in relation to each other they must be in different directions.

From the end of the landing pad, the angle of inclination of the lower plane of the knife relative to the ice plane is equal to the bevel angle on the landing pad welded to the ice drill pipe.

It turns out: the bevels of the landing areas along their narrow sides (ends) determine the angles of entry of the long cutting edges of each auger ice auger knife into the ice.

And the inclination of the landing pads to the center of rotation of the ice drill sets the angle between the cutting edges of both knives. In fact, we see the same picture on the cutting edges of a conventional drill.

And once again I will speak about the persistent desire of some fishermen to find out the sharpening angles of the blades of the ice drill knives and the bevel of the landing pads to which they are screwed.

The very knowledge of these angles does not give us anything, even if we passionately want, based on their sizes, to bring our ice auger to the required condition at home.

I'll explain why it doesn't. Because the bevels of the landing pads for attaching knives on homemade and different branded ice screws can be different, that is, slightly different from each other.

And the angle of entry of the blade of each knife into the ice (in Figure 1 is indicated by a gray dashed line) should be tied to the bevel of the landing pad of its own ice drill.

The upper ray of the angle of entry of the knife blade into the ice divides its sharpening angle in half. Therefore, if we change the sharpening angle of the blade (green arc), say, by 2 degrees, then the angle of the knife entering the ice (gray arc) will change only by 1 degree.

With all our tricks on ice, we will not be able to disfigure the parameters of hardened knives, including their sharpening angles, except that we can dull their blades.

And, if the knives drilled the ice perfectly up to a certain point, but suddenly refused to drill it, then the point, apparently, is not that the angle of their sharpening suddenly changed, which on hardened knives cannot go anywhere.

But the position of the planes of the landing pads, that is, the bevel of the ice drill knives relative to the axis of rotation (shown in the figure by an orange vertical line), even without our special desire, can easily change. As a result, at one “wonderful” moment our ice drill will refuse to drill.

The common denominator for all angle values, relative to which they are calculated by specialists at the manufacturer, can only be the central axis of the pipe, to which the auger spiral and landing beam for attaching the knives are welded. It is also the axis of rotation of the ice drill knives.

Now tie the bevel angles of the landing pads of your ice drill to the axis of rotation, sitting in your cozy kitchen. To tie means to measure them relative to the axis of rotation.

Or come up with another binding on your ice drill, measure all the angles relative to it and start correcting them, grinding down the surfaces of both knife landing areas, say, with a file (if he takes them). This is the only way to manually change their bevels.

You understand that this will be an absolutely stupid and practically impossible job at home, which will completely ruin the ice screw! Because we won’t be able to measure anything properly, and if we change the bevel angles of the landing pads of the ice drill knives, it will only be at random.

We can change the angles of inclination of the knives in space in another way. At the same time, we will not have to damage their landing pads, creating an irreparable defect on the ice drill.

To do this, we just need to change the angles of the knives, but relative to the planes of their seats.

And the duralumin plates shown in photo 1, beveled into a wedge along a narrow end, will help us with this.

The bevel adjustment plates are placed between the upper (narrow) planes of the knives and their landing areas. After which the angles, indicated in Figure 1 by red arcs, cease to be equal to each other , which is what I draw your attention to.

Thanks to the spacers, the angles of entry (inclination) of the wide cutting edges of the auger ice auger knives into the ice change relative to the bevel of their landing areas.

And what this can give us, read on the next page.

***

Sharpening methods

You can sharpen ice drill knives at home in several ways, for example, using an electric sharpener. When using specialized equipment, you need to consider some features:

- When sharpening, you need to moisten the stone with water so that the blade does not overheat. Heating leads to a decrease in the strength of the cutting edge.

- Use a special stop to be able to hold one corner.

- Do not resharpen at very high speeds.

Before you start sharpening on a machine, you need to practice on old metal plates.

Sharpening on electrical equipment:

- Prepare the cutting edge by hand. To do this you need to use a needle file. With its help, rough irregularities, chips, and nicks are removed. Irregularities larger than 2 mm must be ground to the shape of a tooth.

- Secure the knife at an angle of 30 degrees relative to the whetstone. Bring the edge to the required sharpness.

- Turn the part over and repeat the procedure.

You can buy the machine or make it yourself. When purchasing, you need to choose models with the ability to adjust the speed. If you do the assembly yourself, you will need to install a gearbox on the homemade machine.

After processing with a sharpening wheel, you need to bring the blade with felt and GOI paste to working condition.

Straight knives

Straight ice ax knives are the easiest to sharpen. All stages of this process have been described above. It is important to avoid putting too much pressure on the part, regularly cool abrasive surfaces, and wash off metal dust with water.

Step knives

When sharpening stepped cutting edges, you need to take into account that they are double. Each part needs to be sharpened separately. After completing the work, the sharpness of both stages should be checked. The effectiveness of the ice ax depends on the correct sharpening.

Stepped knives (Photo: Instagram / zatochka_oren56)

Rounded knives

Sharpening such blades requires practical skills. It is important to make smooth turns of the cutting edge so that the metal layer is gradually cut off by the abrasive. Too fast movements will lead to damage to the part, slow movements will lead to overheating of the metal.

An ice ax is an important assistant for a fisherman who goes winter fishing. It can be used to drill holes of different depths to get to the water. Over time, the blades lose their sharpness and stop cutting icy surfaces. To correct this shortcoming, you can use different sharpening tools.

How to polish

Regardless of the method by which the ice ax knife for fishing was sharpened, the final step is polishing the surface being processed.

To do this, it is recommended to use a felt wheel and an electric sharpener. A layer of GOI paste is first applied to the surface of the felt. First, the wide edge of the knife is processed, and then the narrow one. For each of them, 250-300 rotations of the circle are enough.

When choosing one or another sharpening option, it is recommended to take into account your capabilities and skills. Proper sharpening and polishing of an ice ax knife allows you to extend their use, make it easier to use, and ensure a good catch.