Serrated and spherical knives

Today on the fishing equipment market you can see a variety of drill cutters. The most common:

- Serrated.

- Oval.

- Universal.

- Stepped.

All of them are designed for different surface types and weather conditions. To choose the right ones, you need to know how they differ:

Serrated blades are an indispensable assistant in the fight against heavily moistened ice. They will help out when winter is already receding and water from the spring sun begins to wash small channels on the surface of the reservoir, abundantly saturating the ice layer. Small contact area reduces drag force. It's worth noting that the blades need to be "break-in" (approximately 30-40 holes), during which time the drilling can be a little aggressive. For some, when it gets from the ice into the water.

Oval (spherical) - suitable for almost all possible types of ice cover on water bodies. As a rule, spherical ones are included in the basic kit with most ice drills from well-known companies that are present on the Russian market. Unfortunately, this form has one critical drawback: the cutters become dull rather quickly, and it is almost impossible to sharpen them at home.

How to prepare knives for use?

Experienced fishermen know that with frequent trips to the pond, the blades of replaceable attachments become dull after just a couple of months. In many ways, this period depends on the quality of the preparation carried out in the off-season. For most fishermen, sharpening ice auger knives at home is not a problem.

Along with the processing of blades, consumables and tools (keys, screwdrivers, bolts, nuts, washers and gaskets) are selected and adjusted. It is advisable to have a separate sealed container for carrying sharps.

You can sharpen blades in various ways; you need to rely on your own abilities and technical equipment. If you have doubts about your own abilities, then it is advisable to take the products to a specialized workshop that has professional equipment. Improper handling of nozzles impairs their performance characteristics and reduces their service life. A high-quality sharpened blade cuts paper without leaving torn edges.

On the machine

Almost every fisherman has grinding equipment, as it is necessary for straightening knives, axes and hooks, turning buoys and floats. Before sharpening knives on the machine, you need to make several corner stands. This will allow you to maintain the correct angle and remove a minimum amount of hardened metal.

In the process of processing products, you should use several wheels, gradually reducing their grain size. When grinding, the iron must not be allowed to overheat, as this leads to a decrease in its strength. The nozzles must be constantly dipped in water until they cool completely.

Using an abrasive stone

If you don’t have a grinding machine at hand to sharpen a knife, a kitchen knife sharpener is a good option. First you need to secure it to the surface by placing it on a sheet of thick rubber. This technique will prevent the block from slipping during operation. The stone is moistened with a small amount of water, after which the straightening process begins.

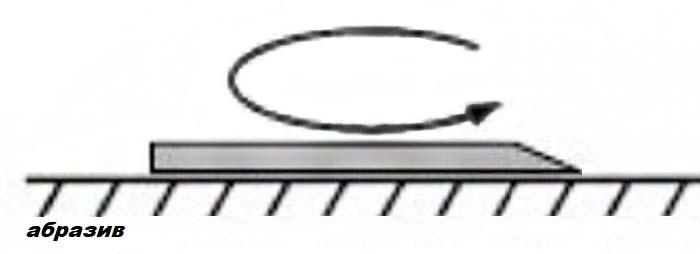

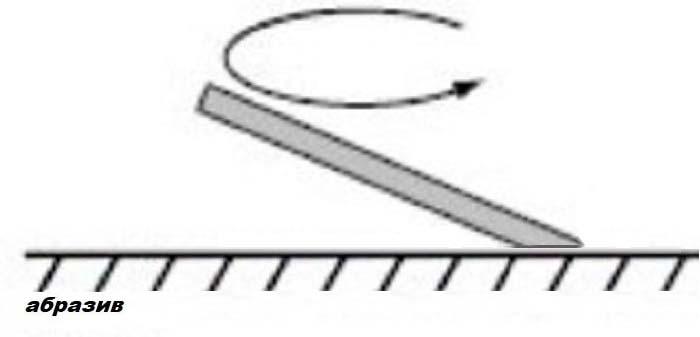

First of all, the large edge of the knife is processed. This is done with soft circular movements with constant horizontal control. The resulting abrasive paste promotes high-quality and uniform metal removal. At the second stage, the part of the blade that has a slope is ground off. Finishing is done with transverse movements.

Using sandpaper

Those who have not previously sharpened ice drill knives can use sandpaper. The strip of abrasive material must be firmly secured to a flat and hard surface. This could be a board or a grout float. You should not use material with large grains - they leave deep grooves on the metal that are difficult to remove.

Circular movements are made in different directions, after which the blade is straightened by longitudinal movement along the sandpaper. Burrs are removed with fine-grained material (zero).

Glass and pasta goyim

These abrasives are used to bring the surfaces of attachments to a mirror shine and sharpness to the level of razor blades. This event has a practical meaning - smooth metal rubs against ice less easily, which helps reduce wear and increase service life. Polishing is carried out mechanically (in a circle) or manually using woolen cloth. The material is first moistened with alcohol, then the composition is applied to it. When processing, care should be taken not to grind off excess or deform the tip.

Variety of shapes and characteristics

During the winter season, ice drill knives are a popular consumable item. Sometimes during one fishing trip two or even three sets fail. This is due to the fact that, as a rule, on all river beds the ice is simply saturated with sand and the instrument becomes completely unusable after a dozen holes. In this case, a fishing secret will help: bend the edge outwards with a metal object from the inside, but this will not help for long.

The following will save you from frequently replacing the cutting parts of the ice drill:

- Selection of high-quality tools and spare parts for them.

- Spare kits must be of the same brand, or an analogue, ideally suitable for the ice auger model.

- Proper use, transportation, cleaning and storage of equipment.

When purchasing you need to consider:

- Features of blade sharpening.

- General geometry.

- Heat treatment level.

- Steel sample.

The importance of polishing knife blades

In general, polishing the working surfaces of the ice drill is very important for the cleanliness and speed of drilling. It is best to carry out polishing on a felt disk, which should be installed on an electric sharpener instead of an abrasive wheel. The disc itself must be thoroughly rubbed with this GOI paste. If the wheel rotation speed is at least 3000 rpm, then polishing takes a couple of minutes. The truth here is that you need to know that the knife must be pressed against the felt circle with its tip and only as the disk rotates.

In this case, the wide surface of the knife, which is directed towards the ice, must be polished first. In this case, you must try not to grab the narrow strip running along the cutting edge. It is also impossible to tilt the cutting edge upward, which will certainly lead to damage to the knife blade.

After this procedure, you can begin processing the upper cutting plane, which has a groove. It is necessary to polish it by approaching the cutting edge. This processing method can significantly improve the cutting angle, which will certainly lead to an increase in the service life of the knife as a whole. By the way, if the surface is not just sharpened, but also polished, it will not be subject to rust for a long time. And polished knives drill ice better, and during the drilling process they do not grind it into small crumbs.

In exactly the same way, it is necessary to polish and process the second edge, which is not fully used for cutting. So, if the knives are properly prepared for cutting, their service life will significantly increase. And if necessary, such knives can be easily sharpened literally on the knee, standing on the ice of a reservoir.

By the way, if there are chips or gouges in the very center of the blade, the depth of which reaches 2 mm, then they cannot have any negative impact on drilling. It is enough to simply remove nicks or burrs from such blades using a block. But if the chip is more than 2 mm deep, then it must be cut into the shape of a tooth, and then sharpened. All knives after such repairs must be mounted on a drill in pairs. Those. The drill should have either new knives or repaired ones.

Video - sharpening an ice screw with a file:

Video - sharpening knives for ice drills:

Replacing blades on ice augers and caring for them

The difficulty in replacing knives arises when the ice auger is deprived of attention from its owner. This is especially true when corrosion occurs. “Our” ice screws have blades and fastening screws that are quite susceptible to rust. Therefore, the first rule of the owner of such an ice drill should be to remove moisture from its parts after fishing. If you don’t do this, the knives will rust literally before your eyes, and the fastening screws will “stick” so that unscrewing them becomes a real problem.

It’s easy to combat corrosion of knives by regularly lubricating them with any neutral oil after removing moisture. If you do not pay attention to the rust that appears, then in the worst case scenario it will “eat” the blade of the cutting edge. Such knives are subject only to radical resharpening.

Another way to prevent corrosion at the initial stage is to treat the surface of the knives with phosphoric acid. I use acid, which is sold in small containers as an active flux for soldering. To obtain a stable phosphate film that prevents rust, it will be enough to evenly apply a thin layer of acid to the surface of the knives with a brush, and after half an hour, remove the excess acid with a napkin and dry the knives in the air. The surface of the knives after this procedure will acquire a matte gray color. Of course, knives will still need to be treated with machine oil later to prevent rust from appearing on the cutting edge, where the oxide film will quickly be erased.

Another operation that allows you to keep knives sharp for a long time is grinding the cutting edge until it shines. On my drill, the ground knives have already been used for a season and a half without any noticeable loss of sharpness, despite the appearance of rust spots. I believe that the knives will still serve for most of this fishing season. However, not everyone can do knife grinding at home. I’ll tell you how to do this without much effort next time.

There are two ways to prevent the mounting screws from sticking. The first is to wrap the threads with plumbing FUM tape. In addition to the fact that the tape does not allow the threaded connection to “stick”, it also seals it. This virtually eliminates spontaneous unscrewing of the mounting screws. You just need to take into account that this tape is a disposable thing. That is, I unscrewed the screws, and the next time I tighten them, I need to do the winding again.

How to choose?

When choosing a Tonar ice drill, you need to consider several aspects.

Selection of drilling diameter

offers three types of drills:

- 10–11 cm - for quick drilling, but such a tool is not suitable for catching large fish, since you are unlikely to be able to remove it through such a narrow hole in the ice;

- 12–13 cm is the universal diameter chosen by most fishermen;

- 15 cm – a drill, which is useful when catching large fish.

Choosing a drilling direction

Ice screws are available in left and right orientation. The company takes into account the different needs of left- and right-handed people when drilling ice and produces devices with different sides of rotation.

Design selection

Ice screws of this brand are available in several types.

- Classical. The handle is on the same axis with the auger. Drilling is done with one hand, and the tool is simply held with the other.

- Two-handed. Designed for high-speed drilling. Here manipulations are performed with both hands.

- Telescopic. It has an additional stand that allows you to adjust the tool to a certain ice thickness.

Weight selection

The weight of the drill is of considerable importance, since fishermen often have to walk more than one kilometer. The weight of Tonar ice drills ranges from two to five kilograms.

Color selection

For the fairer sex, who are partial to winter fishing, we have released a special series of ice screws in purple.

Price

The price of different drill models also differs. So, the simplest model will cost you only 1,600 rubles, while a titanium ice drill will cost about 10,000 rubles.

How to sharpen a cutting edge

It is no secret that any cutting object, no matter how good the material it is made from, becomes dull over time. Drill knives produced in our country are made of fairly soft steel. Therefore, when actively using ice augers, they have to be adjusted several times a season. Ideally, you need to have several sets and, after the end of the winter season, have them all professionally sharpened. If this is not possible, then you will have to sharpen it yourself.

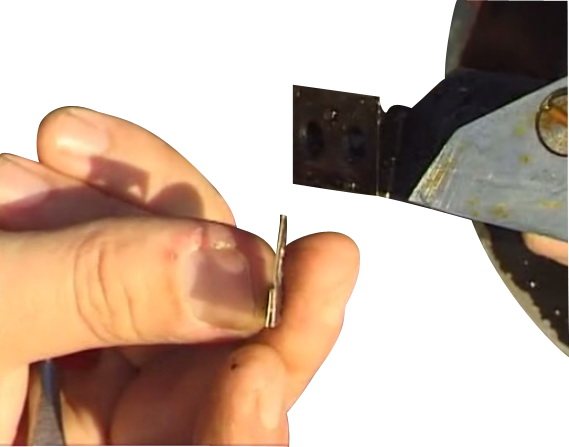

The easiest way is to straighten the cutting edge with a strip of high-speed steel. Many fishermen carry such a piece with them. You can use it to correct the cutting edge while fishing directly on the ice drill. Editing is very simple. You need to forcefully run a piece of such steel along the cutting edge, holding it at an angle. The steel will remove small chips each time. This method can quickly bring ice drill knives into working condition, but this is only a temporary measure.

When adjusting the edge in this way, you need to be extremely careful. The blade can easily injure your hands. In addition, sharpening can only be done from the inside, where the blades have a sharpening angle. Attempts to sharpen them on the flat outer side, where the recesses for countersunk screws are made, will only lead to complete damage to the blades.

At home, sharpening knives for ice drills requires their removal. Blades can be sharpened on any flat surface. To do this, you need an abrasive stone or sandpaper of medium or fine grit. First, large burrs are removed by pressing the knife as tightly as possible against the abrasive surface. Then the pressure can be released. It must be remembered that the sharpening angle of ice drill knives is thirty degrees. We must try to preserve it as accurately as possible. Final finishing can be done by polishing the surface using GOI paste.

Gasket for drill knives for winter fishing

The weather is warm and the ice is already beginning to melt. An ice auger is an incredibly important element of winter fishing gear, and a fisherman spends a lot of time caring for it. And this is not as simple as it might seem at first glance. How much does it cost to properly sharpen ice drill knives? Everything about sharpening ice auger blades at home - conditions, adjustments and tips The question of how to properly sharpen ice auger blades is somewhat controversial. Each fisherman has his own truth. All this is due to the wide range of devices for drilling holes in the ice, designed to extract the catch.

Gasket & auger knives for ice fishing

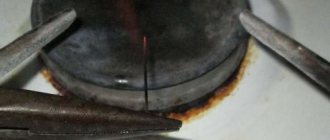

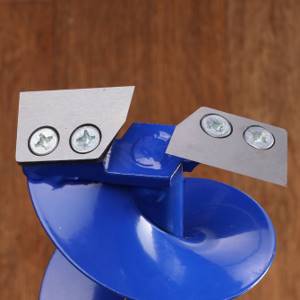

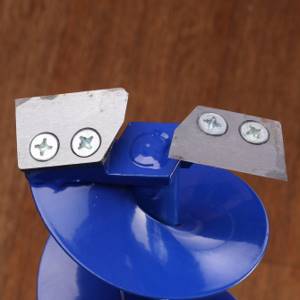

To drill such ice, I have a special homemade drill that cuts both dry and wet ice (Fig. 17).

Rice. 17

To drill through wet ice, we recommend using small iron shims on the drill. They are placed under the knives in order to change the angle of attack. To cut wet ice, reduce the angle of the blades. The drill will drill more slowly, but with less hardening, and will not jam.

Rice. 18

In Fig. 18 shows how the spacers are installed, the angle of the knives is reduced. It is possible to install gaskets under the knives, and we recommend lubricating the drill itself with silicone, and then wet pieces of ice will not stick to the auger, and in cold weather the ice will not freeze either on the auger, or on the attachment point, or on the knives.

Let's drill a couple of holes. As we have already reported, the drill will drill quite slowly, but it will not jam. Thanks to silicone, water droplets roll off the auger and do not freeze.

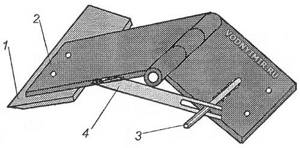

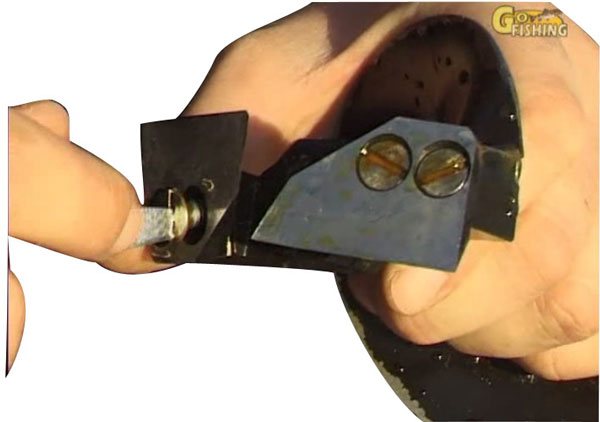

Rice. 19

Contrary to domestic expectations, the ice was now quite dry. Based on this, in order to drill holes faster, we will move the gaskets installed on wet ice to the other side. So, we will set them up for dry ice and increase the drilling angle, after which the holes will be drilled even faster than with the standard position of the knives (Fig. 19).

Rice. 20

We recommend keeping a screwdriver with you at all times. I'll tell you one secret. In most cases, the slot in the head of the bolts breaks off very quickly, and it is impossible to unscrew them. I made a cut on the caps with a file much deeper, thanks to which they can be unscrewed with any screwdriver, even if the bolts are slightly rusty (Fig. 20).

Rice. 21

Rice. 22

In Fig. 21, 22 demonstrate what this gasket looks like: two holes are drilled, an accordion is folded, three bends of a cupronickel plate are made. We rearrange the gasket; accordingly, the drilling angle increases. We also rearrange the knives and start drilling.

With a small and low position of the knives, the hole is drilled in approximately 20 revolutions, and with this position of the knives, while the angle of attack of the knives is increased, the hole will be drilled in 12 revolutions.

How to fish with Chert A catchy fishing rod for winter fishing

drill-screwdriver

Utility and step knives

Universal - also called flat, deserve the attention of anglers due to their ease of maintenance. It’s easy to sharpen and straighten the blades yourself, thereby avoiding additional costs for the services of a professional

But when working with a flat blade, you will have to put in much more effort to drill the hole.

Stepped - this equipment is indispensable when the temperature drops below -15 °C. Two blades located side by side create a crumbling effect, which for frost-hardened ice is much more effective than a cutter, without unnecessary loads. In warmer temperature conditions, these auger blades are ineffective. Sharpening them yourself is not as easy as flat ones, but it is possible.

The lineup

There are more than 30 modifications in the Tonar ice drill model range. Here are a few that are in particular demand.

- Helios HS-130D. The most budget model. The drill is a two-handed modification, which is designed to make holes with a diameter of 13 cm. Its upper handle is offset from the axis of rotation by 13 cm, and the lower one by 15 cm, which allows you to easily twist the drill into the ice. The kit includes flat Skat knives; if desired, they can be replaced with HELIOS HS-130 spherical knives, which are sold complete with fasteners.

- Iceberg-arctic. One of the expensive models in the line. It has a drilling depth of 19 cm. The solid-drawn auger has an increased pitch, which facilitates the process of freeing the hole from sludge.

- Indigo. The model is designed for drilling ice up to 16 cm thick. The drill is equipped with a removable tip made of composite materials, which resists abrasion well, and spherical knives are fixed on it. The weight of the device is 3.5 kg.

- "Tornado - M2 130." A two-handed device designed for use in sport fishing. The drilling depth of this tool is 14.7 cm. It weighs 3.4 kg. The kit includes an adapter mount that regulates the passage of the drill in ice, as well as the length of the tool. The ice drill is equipped with a set of semicircular knives, as well as a convenient and durable case for carrying and storing the tool.

Ice auger storage rules

After work, the drill must be placed in a well-heated room. After the instrument has thawed, it should be wiped with a rag. Several times a year, before the next use, the ice screw should be lubricated at the joints.

It is important to remember that the drill should only be transported folded, in a protective case. This reduces the likelihood of tool damage to a minimum. If damage to the auger is detected, it must be repaired immediately. Otherwise, corrosion may occur, which will render the tool inoperable.

It is important not to forget to lubricate the ice auger in time and paint the auger if there are scratches on it. The storage area must be dry and cool. If all measures are taken, the drill will last for a long time.

Subscribe to

our channel in Yandex Zen

How to sharpen ice drill knives correctly

To get fish out of a frozen pond in winter, you need to have a good ice auger with sharp knives. You can, of course, get by with a grandfather’s pick, but for ice more than 40…60 cm thick, an ice auger is still better.

On lakes, ice ax knives remain sharp for quite a long time. But on rivers like the Akhtuba and especially the Volga, where there is a lot of drift sand in the ice, the knives become dull instantly. You have to change 2…3 pairs of knives per day. In short, you have to sharpen the knives for the ice drill after every fishing trip on the river.

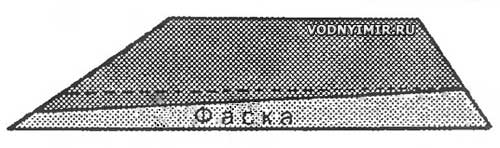

It is known that when sharpening knives “by eye,” the blades often come out with some defects. Thus, the sharpened chamfer of the cutting edge often becomes skewed (Fig. 1).

|

It happens that the sharpened chamfer becomes oval or with a fracture (Fig. 2).

| Rice. 2. Oval chamfer (a) and chamfer with a break (sharpening defects). |

Another sharpening defect includes the formation of a burr directed towards the chamfer of the cutting edge (Fig. 3).

| Rice. 3. “Incorrect” burr (sharpening defect). |

Although, in general, a slight burr oriented in the opposite direction is allowed. I note that both of these burrs are removed by finishing the knives on a fine-grained block with a flat surface or on a sheet of sandpaper (zero), spread on a flat surface, for example, on a sheet of glass. Well, when sharpening knives, it is necessary to maintain the required (optimal) cutting chamfer angle (Fig. 4).

| Rice. 4. When sharpening, it is necessary to maintain the existing (optimal) sharpening angle of the blade: a - before sharpening; b - after sharpening. |

It is clear that all the defects listed above, as a rule, greatly impair the cutting characteristics of knives

But it is no less important when sharpening knives by any method to prevent the metal from darkening, that is, its overheating (burnout). And in order to prevent overburning, during the sharpening process the knives should not be pressed with great force against the sharpening stone, and they are also periodically cooled by immersing them in cold water

Check the quality of knife sharpening in the following simple way. Press the knife blade against the fingernail, placing the knife with the chamfer up and at an angle of 20...30° to the nail. If the knife cuts into the nail when pressed lightly, then you won't have to sweat when drilling holes in the ice. If the knife starts to slide along the nail, it is dull. Using a fingernail, check the sharpness of the knife along the entire length of the cutting edge.

As already mentioned, sharpening knives “by eye” often does not give good results. Therefore, I designed a special device for this purpose, which allows me to reduce possible sharpening defects to a minimum. And below I will tell you about it in detail.

Ice screw knives. Which ones are better?

All fishermen who are passionate about ice fishing know that the winter fisherman’s first friend is an ice screw. And drilling depends on the type and quality of the knives. Over the long years of the evolution of tools for making holes in ice, man went along the path from an pick to an auger-“spoon”, then they came up with a “ring”, followed by a “cylinder” or the so-called “glass”. As the design of ice drills changed, the cutting surface also changed. But progress does not stand still. And now all winter fishing enthusiasts use auger ice screws. Modern augers have undergone many improvements over the years, but even more experimentation has been done with ice auger blades. After all, it is not a drill that drills, but the correct cutting surface of removable knives or a replaceable removable head.

To the simple question “which knife for an ice drill to choose,” you will answer me that now this is not a problem. You come to the store and say what kind of drill you have, they offer you knives. But not everything is as simple as it seems at first glance. In fact, there are a wide variety of ice drill knives on sale. But they all differ in price, shape, steel, sharpening angle, purpose and much more, not to mention the location of the mounting holes. With such variety, of course, you will need a guide to choosing knives.

Let's talk about the shape of ice drill knives

For Russian and imported ice drills, manufacturers now produce several forms of knives, such as

- spherical;

- semicircular;

- universal;

- stepped;

- serrated.

All of them are working, but are designed for different models of drills and different drilling conditions. About all types in order.

Knives for ice auger LR-130 Tonar 235 for 1 set. Knives for ice auger ICEBERG-130(R) for V2.0/V3.0 Tonar 330 for 1 set. Knives for ice auger LR-130 (SKAT) Tonar 155 for 1 set. Knives for ice auger ICEBERG-130(R) for V2.0/V3.0 (wet ice) Tonar 330 for 1 set. Knives for ice auger HS-130 (SKAT) Tonar 155 for 1 set. Knives for ice auger HS-130 (semicircular - wet ice) Tonar 280 for 1 set. Knives for ice auger HS-130 (semicircular) Tonar 280 for 1 set. Knives “Light Ice” 130(L) Tonar 280 for 1 set. Knives LR-130(R) Tonar 235 for 1 set. Knives LR-150(R) Tonar 270 for 1 set. Knives LT-180(R) TORNADO Tonar 365 for 1 set. Knives for ice auger LR-100 Tonar 190 for 1 set. Knives for ice auger HS-150 Tonar 300 for 1 set. Knives ICEBERG-160(R) V3.0 Tonar 365 for 1 set. Knives HELIOS 150(L) (semicircular - wet ice) Tonar 300 for 1 set. Knives for ice auger LR-150 Tonar 270 for 1 set. Knives LR-150(L) (SKAT) Tonar 175 for 1 set. Knives HELIOS 130(R) (semicircular / wet ice) Tonar 280 for 1 set. Knives for ice auger HS-110 (semicircular) Tonar 235 for 1 set. Knives “Light Ice” 150(L) Tonar 310 for 1 set. Knives for ice auger LR-100 (SKAT) Tonar 150 for 1 set. Knives for ice auger HS-110 (semicircular - wet ice) Tonar 235 for 1 set. Knives for ice auger LR-180 (in case) Tonar 390 for 1 set. Knives for ice auger LR-080 Tonar 190 for 1 set. Knives ICEBERG-130(L) for V2.0 (wet ice) Tonar 330 for 1 set. Knives LT-180(L) TORNADO Tonar 365 for 1 set. Knives ICEBERG-130(L) for V2.0 Tonar 330 for 1 set. Spacer for knives for LR-100 Tonar 110 for 1 set. Knives ICEBERG-110(R) for V2.0/V3.0 (wet ice) Tonar 325 for 1 set. Knives ICEBERG-110(R) for V2.0/V3.0 Tonar 325 for 1 set. Knives LR-100(R) Tonar 190 for 1 set. Knives INDIGO-120(R) (wet ice) Tonar 315 for 1 set. Spacer for knives for LR-130 Tonar 110 for 1 set. Knives INDIGO-120(R) Tonar 315 for 1 set. Knives LR-080(L) SPORT (left rotation) Tonar 190 for 1 set. Knives ICEBERG-110(L) for V2.0 Tonar 325 for 1 set. Knives ICEBERG-110(L) for V2.0 (wet ice) Tonar 325 for 1 set.

Spherical knives

– such knives are found on Mora and Rapala ice screws. These are the two most famous foreign companies engaged in the production of ice augers and knives for ice augers: Mora from the Swedish company Ericson and Rapala from the Finnish international concern Normark. The spherical shape allows the angler to easily drill through both dry and wet ice, regardless of its density. Spherical knives have only one disadvantage - sharpening. It negates all the advantages of Mora's ice drill knives. This is problematic to do at home, and you have to replace the entire cutting head, since they are not sold separately. The cost of such a replacement will cost you the same price as a new ice auger with a set of knives from a domestic manufacturer.

Semicircular knives

for ice augers are especially popular among amateur fishermen. They are created for those who go fishing in both frost and thaw. A drill with semicircular knives puts less strain on your hands when drilling. Knives of domestic production have the same center-to-center distances of the mounting holes and therefore knives for the Tonar 130 mm ice auger will also fit the Nero 130 mm ice auger. The advantage of semicircular knives marked “wet ice” is manifested on the wet, spring surface of reservoirs simply splashing with moisture. Biting into the upper crust, they easily pass through wet ice. Semicircular knives are also difficult to sharpen yourself, but their price is several times cheaper than imported ones. Therefore, you can always have a spare set of knives with you, and upon arrival from fishing, give them to professionals for sharpening.

Utility or flat knives

. There are a large variety of such knives from different manufacturers. The difference between the models is the size of the angle between the two cutting surfaces. The closer this angle is to 90 degrees, the more suitable such knives are for drilling into soft ice. By reducing the angle, the knives cut hard ice more aggressively in cold weather. But the edge has an acute angle and is more brittle when dropped sharply onto ice or when it gets into a hard foreign layer of ice (branches, pebbles). The center-to-center distances of the holes of such knives are also the same for many manufacturers, so the knives for the Tonar 100 ice auger will fit “100th” diameter ice augers from other manufacturers. An example of such flat knives produced in Barnaul are Skat ice drill knives.

Their peculiarity is that they are screwed on. This is a more secure fastening than a screw.

Step knives

Recommended for cold weather and hard dry ice. As the temperature drops below -15C, the properties of the ice cover change, and it is at this time that stepped knives will help you; they can easily solve the tasks. Crushing hard ice, they quickly reach the water. At warmer temperatures, unfortunately, they are not so effective, but we also have frosts for a couple of months, which means that step ones should be in the arsenal of a real winter fisherman.

Serrated

or, as they are also called,

“Beast” knives

for ice drills - this model is interesting because it can be made from a flat knife that has already been used. To do this, you need to cut “toothed” grooves across the cutting surface. In practice, the critters performed well on a river with sandy sediments in the ice.

For the convenience of buyers, manufacturers write that specific knives are made for dry or wet ice. As mentioned above, the difference is in the sharpening angles. In practice, different angles of attack of knives give different drilling speeds for the same ice drill. You've probably noticed that with only knives the drill moves smoothly and you reach your water target without any effort. And when using other knives, under the same weather conditions, the drill passes through the ice layer faster by a couple of turns, but a little more effort may be expended.

We are all different, so you should choose both the ice auger itself and the knives for it. I prefer fast aggressive drilling, while others find it more pleasant to make a little more turns of the handle without making any effort. But not everyone knows that you can change the angle of attack without changing the knives. This can sometimes come in handy on a pond when the air temperature and ice structure changes during fishing. When the temperature dropped sharply to -20C, Russian craftsmen came up with the idea of installing a spacer for knives

, thereby increasing the angle. The method is effective, but not very reliable. The knife no longer holds tightly and becomes more brittle.

How to sharpen ice drill knives

When you go out on the ice, all sorts of situations happen. You can accidentally get on a frozen stick or a layer of sand in the ice or some other solid foreign bodies, thereby damaging your drill. I always have several sets with me. Some are the same as those already screwed, and two sets for other conditions. But what to do if you don’t have any spare ones with you? How to sharpen the knives of an ice drill yourself, because sharpening knives when fishing is problematic, but you can correct the cutting surface in order to somehow finish the fishing. To do this you will need a small flat abrasive stone. Without unscrewing the blades from the ice drill, run the block along the cutting surface along and down several times. This correction will save the fishing, but upon return the knives will have to be sharpened. If you do not have professional skills, then we do not recommend sharpening ice drill knives yourself, because you need to press the entire surface to be sharpened onto the abrasive at exactly the same angle, and not everyone can do this and failures in sharpening appear.

To make sure of the quality of the restored knives, you can carefully take the knife with two fingers and run it along a sheet of newspaper. It should be cut, then the knives can be put back in place.

With good knives, not only meter-long river ice, but also the thicker ice of the Far North are not scary. I’ll tell you one more “secret”, there are many varieties of knives for an ice auger of 100, but instead of the hundredth size, you can buy knives for an ice auger of 130. Drilling will not be so comfortable (the auger will move left and right when drilling), but the hole will have a larger diameter. This trick can be used when you find a fish, but it just doesn’t fit into the hundredth diameter and you don’t have a second drill on hand, but you have spare knives of a larger diameter. The center-to-center distance on knives of 100 and 130 diameters is the same - 16 mm.

Which knives are suitable for Barnaul ice screws Tonar

Correspondence table of knives to TONAR ice screws

Recommendations for installing knives

And in conclusion, a few more recommendations for installing knives on an ice auger.

First you need to unscrew the old knives from the drill. If they are rusty and cannot be unscrewed, you can gently tap them with a rubber mallet and unscrew them. If this does not help with “sticking”, you can try soaking it with kerosene or WD-40. To do this, pour it into the mounting holes on the back of the knife platform and leave it for a couple of days. The main thing when dismantling is not to rip off the screws or break the knives, otherwise you will have to drill out these screws later, and you won’t be able to restore the knives like that.

Prevent sticking

It’s always easier than dealing with its consequences. There are two ways here too.

The first is to wind several turns of thread with Fum tape when installing new knives.

. The tape will prevent it from rusting and sticking, and will also help the screw to fit more tightly. Knives screwed with a seal will not unscrew on their own. But don’t forget, the winding is disposable and when changing knives, the fum tape needs to be updated.

Another way is to apply thick graphite lubricant to the threads

For further ease of use, you can immediately replace the slotted screws with hexagon screws. The wrench itself is much smaller than any screwdriver, and the force transferred to the screw is greater than to slotted screws. If a regular screwdriver slips off a screw, injury may occur. The hex key hardly slips. When installing and removing knives, you must protect your hands from cuts.

Having removed the old knives, we take out new ones. Knives for Barnaul ice screws used to be produced in a box, wrapped in oiled paper, but now they come in a lightweight blister that does not allow moisture to pass through. New screws are included with the knives. Use them or replace them - it's your choice. But it is best to tighten new knives with new screws, and leave the old ones complete with the old knives. You need to install the knives on the ice auger in the same way as the previous ones.

Correct installation of knives on the Tonar ice drill

identical to drills from other manufacturers. If you have a new drill in your hands and no knives are installed on it, then first unscrew the screws from the head of the ice drill. The knife should be positioned with the cutting edge up towards the ice drill head (as a hint - chamfers for screws). The screws are tightened in relation to the vertical drill from bottom to top. The area under the knives and the knives themselves must be clean. Screws are well tightened. Otherwise, you can throw off the correct angle. The blades of the knives should move towards each other.

Tips for storing ice augers and knives for them

- When transporting an ice auger, always wear case

on knives. This will protect you from cuts, and if the drill falls, the knives will not break.

- It is better to take with you on a fishing trip a screwdriver that matches your screws, or a wrench, a piece of abrasive stone, a spare set of knives and a rubber hammer.

- When fishing, after drilling a hole, the drill should not be placed on the ice. There are several reasons for this. Firstly, for security reasons. Each of you can remember several stories of falling on a lying drill and open knives of your friends, acquaintances or “acquaintances of acquaintances”. Secondly, lying wet knives freeze, snow sticks to them, after which it becomes difficult to drill with them. But if, immediately after drilling a hole, you drill a drill nearby, the knives will remain dry and clean. It is enough to cross the ice literally 10 centimeters.

- Even if your knives are frozen, under no circumstances should you hit them with metal objects, such as a ladle or a regular hammer. This can be dealt with by either gently tapping the frozen ice with a hammer with a rubber tip, or lowering it into a hole where the water will help the knives thaw.

- When you approach the intended fishing spot and lower the drill onto the ice to drill a hole, do not abandon it. No need to chisel the ice with knives - they have the very tip of the knife breaks

and this makes them work worse.

- You cannot drill old holes. It's better to drill a new one nearby. Pulling a fish a meter or two is easier than removing a jammed drill. The ice structure in a frozen hole is not uniform and drilling is much more difficult.

- If strangers come up to you and ask for a drill to drill a hole, it’s better to help and drill it yourself. After all, there is no certainty that your knives won’t be broken simply due to your inability to handle an ice auger.

- There is no need to put any effort into the drill. If the knives “whistle” on the ice, then pressure on the drill will not help. It’s better to look at the knives, most likely you need to tighten the loose ones or replace the dull ones, but do not put pressure on them. Whole knives can always be sharpened, but broken ones are much more difficult to restore.

- At the end of fishing, it is better not to tap the ice auger and knives against frozen ice. If possible, bring it into a warm place so that it thaws on its own. Then wipe the ice auger and knives dry to prevent them from rusting during storage.

- When putting the drill away for summer storage, be sure to lubricate the knives with machine oil.

Winter fishing is an excellent form of recreation. But before you can get to the fish, you need to drill through the ice cover. This means you should have a reliable friend in your hands - an ice screw. Barnaul knives for ice screws produced by the Tonar Group of Companies are made wisely. We know everything about winter because we live where winter is longer than summer. And for twenty years now we have been working on improving ice drills and knives for them.

How to sharpen ice drill knives at home

Loading …

- Abrasive stone (aka corundum or SiC). The shape of the stone itself is not important, the main thing is that its surface is perfectly flat. Coarse grain will not work here; you need to take a medium or fine-grained abrasive (if you compare it with sandpaper, then this is H4-H6). It should be taken into account that after 5-7 sharpening procedures, the surface will no longer be flat and a small depression will appear, which negatively affects the final result. It is better not to save money and purchase a new stone every time the corresponding signs of deterioration are noticed on the old one.

Sandpaper. A piece of material is glued to a flat surface with glue or double-sided tape. It can only be used once, but will be as effective as an abrasive stone.

When the preparatory work is completed, the knives are sharpened on an ice drill:

- The initial rubbing of the working surface of the knife is carried out. During the process, all hangnails must be removed, while movements occur in a circle.

The blade is pressed against the abrasive and circular movements are made. The angle of inclination is indicated in the schematic drawing. If the blade is too small to hold firmly in your hands, you can attach the plate using the standard bolt holes.

The process continues until marks of sharpening appear on the cutting edge. The tightness of the surface is determined by the marks that are formed from the grindstone.

The main stage of sharpening is completed, all that remains is to check the quality of the work performed. To do this, take a sheet of paper with two fingers of your left hand, and a blade with the second. If the cutting is carried out without obstacles and effort, the test is passed.

Editing and polishing

In some cases, there is no need to thoroughly understand how to sharpen ice drill knives, but it is enough to make minor adjustments to restore the sharpness of the blade. The work is carried out using the finest sandpaper with a paper base. You will also need a flat surface for fastening (glass, a piece of mirror, fiberglass).

Sandpaper is laid on the surface and secured along the edges with tape. The surface itself is laid on a damp cloth, which prevents slipping. The first step is to level the back of the blade. It will be enough to perform 20 to 30 circular movements

The cutting side is leveled by moving towards you; here it is important to maintain the angle of inclination. The procedure ends with a test on paper, which is described above.

The information presented in the article gives an idea of the differences between domestic and foreign knives, and also indicates what types of knives can be sharpened independently. The process itself is not particularly difficult and can be performed using simple tools. You can clearly learn how to sharpen ice drill knives by watching the video posted in the material.

How to choose an ice screw for fishing

The main characteristic of the drill, which you definitely pay attention to, is the diameter. You need to consider what kind of fish it is used for and choose the optimal size. The most acceptable diameter for an amateur is considered to be 110-115 cm.

You can find domestic and foreign instruments on the market. Which one to choose is a matter of taste. It cannot be said that Russian instruments are very different from their foreign counterparts. The quality of workmanship is approximately at the same level, but Russian ones are still slightly inferior in quality of materials and assembly. Each ice auger will have its own pros and cons that cannot be considered when purchasing.

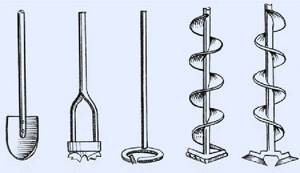

Design and features of ice drills

Designs such as “glass”, “cup”, “ring” and “spoon” were invented at different times and have their own advantages and disadvantages. Thus, the “glass” design of the ice drill is outdated, has not been produced by industry for a long time and can very rarely be found among ice fishing enthusiasts. In addition, such an ice drill can only make holes of small diameter. The drilling depth is also small. The fisherman has to spend a lot of time removing ice chips from the hole and cleaning the cutting part of the ice drill.

The cutting part of the spoon-type ice drill requires special sharpening. This ice drill is good for drilling previously made holes. The diameter of the “spoon” is 130 mm.

In a cup-type ice drill, the working part is made in the form of a hemisphere. It is labor intensive in production. Since it is practically not produced by industry, amateurs make it themselves. In addition, it requires complex adjustment of the head, knives and their teeth, as well as special metal for them.

The principle of operation of the “ring” ice drill is based on the rotation of a metal blade in the form of a ring with numerous cutters. This ice auger requires careful ring adjustment and is heavy. The extension rod and the ring are rigidly connected to each other by welding, which makes the ice drill difficult to transport. Although it has certain advantages. Firstly, the diameter of the holes is large (from 120 to 310 mm), and secondly, it is possible to make cylindrical ice samples.

Despite a slight increase in the severity of drilling, many anglers prefer an auger ice auger. The job of the auger is to clean the hole from ice crumbs and spread them onto the surface.

The optimal screw length is 400mm. But its length can be up to 700 mm.

Different types of ice screws

In the fishing community, an ice screw is also called a brace. The vast majority of modern fishermen use auger rotators with a cutting head. Several decades ago, ice fishing enthusiasts often used other models, which, due to their lack of efficiency, are practically not used today.

The most common model of ice ax for winter fishing in the seventies was the spoon drill. The main element of this drill was a sharp metal plate that cut ice. With a certain skill, this tool could drill about a dozen holes in a day, but this required a lot of labor and quite a lot of time. If the ice on a reservoir exceeded half a meter in thickness, then the “spoon” brace became completely useless.

Another design often used in the last century is the “ring” drill. A characteristic feature of the operation of this tool was that it did not crush ice throughout the entire volume of the hole, but cut out a column of ice along the circumference, which was subsequently drowned in the resulting hole or pulled out to the surface. Drilling a hole with such a brace took a lot of time from the fisherman and caused a lot of unnecessary trouble.

The ice auger for winter fishing has proven its high efficiency over the past decades. It drills perfectly into ice of any thickness without requiring much effort. Crushed ice generated during drilling rises to the surface due to the rotation of the spiral auger, which saves time on cleaning the hole.

Care Tips

At its core, the tool is quite simple and does not require special storage and maintenance conditions. However, if you follow the recommendations below, you will be able to significantly extend its service life:

- After drilling, the tool should not be placed directly on the snow. This will cause ice to form on it.

- When returning to a warm place, the auger and knives must be wiped dry.

If ice has formed on the cutting knives, then under no circumstances should you knock them on a hard surface. To melt the ice, you should place the blades in heat or dip them in water; in extreme cases, you can scrape off the excess. The folding structure must be lubricated periodically.

Rules for using an ice auger

The first thing to remember when using a drill is that you should never knock the knives on the surface of the ice. With such use, the blades may become deformed, which will render the drill inoperative. And also, due to impacts, the fastening of the knives may break, which is almost impossible to repair on your own.

Read: What to feed fish in winter?

Every person involved in winter fishing must remember that a wet tool cannot be placed in the snow. Otherwise, ice will freeze on the ice drill blades, which will interfere with the normal operation of the drill. To clean the tool after drilling, you need to gently shake it and screw it into the ice at a distance of about 10 cm. This way you can clean the drill from fine ice. But it is worth remembering that in severe frosts it is not recommended to do this; the ice auger may simply freeze into the icy surface.

After work, when ice has formed on the drill, under no circumstances should you break it off with a hammer or metal tools. This cleaning method will lead to deformation of the knives. The instrument must be placed in a warm room where it will thaw on its own. After this, the ice screw must be wiped with a rag to remove excess moisture.

Removing ice with fire is also a bad idea. Due to heating, not only the drill knives can be damaged, but also the auger coating. All this will render the ice screw unusable.

In extreme cases, with due care, ice from the surface of the knives can be removed with a wooden stick.

Read: How and with what to insulate a winter tent?

Before using an ice drill, you need to make sure that there is no sand or small debris on the ice surface. Drill knives can easily become dull due to small abrasive particles.

Therefore, you need to take additional sets of blades when fishing.

Knife fastenings tend to come loose at the most inopportune moment. Therefore, it would be a good idea to take a screwdriver on a fishing trip to tighten the connection.

Peculiarities

Tonar ice screws are created using innovative technology, which allows us to produce high-quality products that are easy to use. Drills of this brand have a number of advantages.

- Price. The price of Tonar ice drills is quite affordable, so the tool is accessible to most of the population. This company participates in the import substitution program, so its products have an excellent price-quality ratio.

- Large model range. The buyer will be able to choose a modification of the drill to suit his individual needs.

- Reliable polymer coating. The paint on the device will not peel off even after repeated use, and it will not rust.

- Design. All ice axes have a convenient folding mechanism, which does not play when using the tool and unfolds easily. When carried, such devices are quite compact.

- Pens. They have a rubberized coating and remain warm even in cold weather.

- Many models can be equipped with an electric motor.

Ice drill knife sharpening device

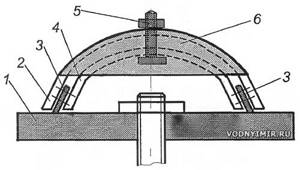

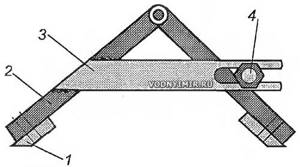

The procedure for manufacturing a device for sharpening ice drill knives is as follows (the general view of the device is shown in Fig. 5). For such a device you will need two pieces of steel strip 3...4 mm thick, 50...60 mm wide and 160...200 mm long. You can use a piece of a car spring as a strip, but it will be difficult to bend it to the desired profile.

|

First, we make the body of the device by bending steel strips in the form of arcs so that the chamfers of the knives, tightly pressed to the ends of the arc, are not only parallel to each other, but also in the same plane. Then, when these knives are simultaneously sharpened on the end side of the emery wheel, the knife blades will acquire the same sharpening angles (see Fig. 5). The knives for the Leningrad ice drill in the device should be located at an angle β=115°.

Having made the arc of the body of the device, we bend a pressure plate from the same strip, with the help of which we will fix the knives to be sharpened on the arc of the body (Fig. 6).

|

After this, we drill a hole for the M12...M14 bolt in the housing and in the pressure plate. Next, having tightened the body and the pressure plate with a bolt and nut, we clamp the knives between them (see Fig. 5) and check the accuracy of the fit of the knives to the end surface of the emery wheel. If the knives are not positioned at the desired angle (the chamfers do not fit exactly to the emery wheel), the device is adjusted to perfection by bending the body arc accordingly. If the knives are installed correctly and no adjustment is required, the structure is disassembled and stiffeners are welded to the body arc on both sides (see Fig. 5)

Please note that the pressure plate should be 0.5...1 mm narrower than the body arc, so that when clamping the knives it does not cling to the stiffeners. That's it, the device is ready

It is more convenient to sharpen knives on an emery stone rotating in a horizontal plane. In this case, after wetting the knives with water, the latter stays on the knives and stone longer, ensuring the cooling of the knives and the preservation of the stone. Dip your knives into water more often while sharpening, which will help avoid overheating (burnout) of the steel.

The disadvantage of the device shown in Fig. 5, is the impossibility of sharpening knives with different cutting chamfer angles. But each manufacturer offers its own options, although it seems to me that the Leningrad one is the best. Therefore, for each type of knife it is necessary to make its own device.

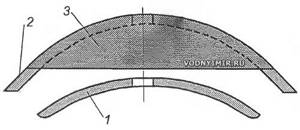

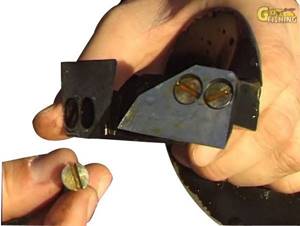

But you can also make a universal device. This is exactly the design that was suggested to us by A. Semenchenko, our colleague, fisherman, veteran of ice fishing on Akhtuba and the Volga. The device design he proposed, shown in Fig. 7, allows you to sharpen knives with any sharpening angle of the cutting edge. By smoothly changing the angle between the arms of the device on which the knives are fastened with screws, you can fix the desired position of the knives relative to the plane of the emery stone.

|

To make this version of the device, you will have to find a suitable door canopy (it is better that it has minimal play), as well as an M8...M10 screw with a nut. Holes with a diameter of 6...7 mm are drilled in the arms (cards) of the canopy for attaching knives to them with screws (of course, the knives must have corresponding holes). A fixing plate with a slot for a fastening screw is made from a steel strip 2...3 mm thick. Both the plate and the screw are welded to the canopy cards, as shown in Fig. 8. The device for sharpening ice drill knives with certain cutting chamfer angles is ready.

|

It may happen that you have to sharpen knives in which the location of the holes for attaching them to the canopy does not correspond to the location of the holes intended for this purpose in the canopy. Then it is necessary to drill additional holes in the arms of the canopy, corresponding to the mounting holes of the “non-standard knives”. And then the device will become even more universal. To give the device greater rigidity, fixing plates and screws can be welded on both sides of the canopy.

We wish the fishermen good luck both in summer and winter.

Share this page on social media. networks or add to bookmarks: