| Place | Name | Characteristics in the rating |

| The best drag sled for a motorized towing vehicle |

| 1 | Forza | Best Capacity |

| 2 | Norfin Taiga | Highest quality |

| 3 | Polymer sheet SVP-150 | The most passable trails on loose snow |

| 4 | Master Pro 150 | Optimal combination of price and quality |

| 5 | Solar | Best price |

| The best sled drag for a snowmobile |

| 1 | Safari polymer sheet | Better maneuverability and stability |

| 2 | Yaman Tundra No. 4 | A light weight |

| 3 | G.L.Q. | Choice of hunters (fishermen) |

| 4 | Polymer Group Rex | The most durable |

| 5 | Station wagon - Comfort 220 | High level of comfort |

Dragging sleds significantly increase the practical capabilities of snowmobiles and motorized dogs for transporting goods. In winter conditions, this is the best solution for fishermen and hunters, and also allows residents of remote villages to solve various problems.

The rating includes drag sleds that can serve as a trailer for motorized towing vehicles or snowmobiles. The best models were selected based on characteristics such as load capacity, reliability of fastenings, and strength. The selection also took into account customer preferences and the cost of the sled.

Structure

Before we get started, we need to understand how they work.

To do this, you need to find drawings of the structure of the sled on the Internet. After you have studied all the diagrams, you need to decide what size the sled will be and how you will use it. Read here - DIY sewing machine: primitive models and tips on how to build a machine (100 photos and videos)

It is known that to increase the stability of a sled, it is necessary to increase the distance between the runners. However, you should not forget about the roads on which you plan to travel.

Other types of sleds

In addition to drags, there are other types of fishing sleds that are used by “penguins”. Among them the most famous are:

- Finnish;

- inflatable;

- on skids.

Each option has the right to life, its pros and cons, design features.

Inflatable

Inflatable sleds for winter fishing are made of rubber and PVC. Products made from polyvinyl chloride are more reliable and durable. However, this option has its drawbacks:

- the need to inflate the sled before fishing;

- can be easily damaged by contact with hummocks or gear and sharp elements of equipment;

- it is necessary to additionally secure the equipment so that it does not fly off when moving on uneven ice or snowdrifts;

- an insufficiently loaded sled can easily be blown away or overturned by a strong gust of wind.

The main advantage of an inflatable sled is its compactness during transportation and storage. They take up almost no space and are light in weight.

On skids

Fishing sleds on runners are the oldest model used by winter fishing enthusiasts. Any children's, metal, wooden ones are suitable for going out on the ice. Most importantly, they allow you to transport equipment, tackle and gear, making it easier to move from one promising place to another.

The disadvantage of sleds on runners is their weight compared to plastic drags. Also, not every model is strong and durable. They are not comfortable when moving on uneven ice, but they do a good job on snow cover.

Manufacturing instructions

As we noted above, our sleds require plastic pipes. They are necessary for the runners, given that the runners must be flat and the pipes round, they must first be heated so that they straighten. They heat it either with a special heater or a hair dryer, but with the latter very carefully and carefully monitoring the heating. Otherwise, the pipe may be damaged.

We recommend reading: Scooter for children over 6 years old: how to choose a model for a girl and a boy?

After heating, the future runners are placed on a flat place under pressure until they cool completely. And only after that they mark the front side and bend it at an angle of 30 degrees. A strong frame base is welded from a profile metal pipe, on which the runners are subsequently placed. A drawbar is installed in front of our sleds, reinforced with a steel sheet, and a bushing is placed in it. Then the plywood flooring is fixed, welded and the connection at the welding points is checked for strength.

Considering that we make snowmobile sleds with our own hands, many technical solutions cannot always be implemented. A motorized stroller will make an excellent sled, just put it on runners. True, this design is only suitable for powerful snowmobiles, since its weight is still significant.

You can also use the sleigh principle to make a do-it-yourself cart with wheels for an all-terrain vehicle or ATV.

Volokushi

This device is a lightweight, often wooden structure, similar in type to a sled. Although sleds are typically used for dog or reindeer sleds, they can also be easily retrofitted for a snow machine. Drags are valued for their small weight and size, ease of operation and the speed with which the drags can be loaded and unloaded. Their body does not freeze. However, this equipment has a big drawback - due to its design features, the front is subject to deformation. The purchased version is presented in the form of a plastic trough on skids.

Passenger

Passenger snowmobile sleds are not much different from cargo sleds. Only the basic design of cargo sleds is made of a strong base, skis and a low platform, and passenger models are designed for one or two people. In Russia, even in specialized stores it is very difficult to find them. To use such a design, the snowmobile must be very powerful, such as the Yamaha, Buran, Yarmak, Russian Mechanics, Viking, Stealth and other machines.

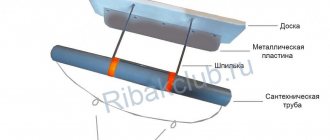

To increase passenger comfort, the design of the sled can be supplemented with shock absorbers. The housing is made as a cabin, which also additionally contains lighting and heating elements. The booth itself is created from plywood sheet, plastic sheet or other similar materials. For skis, both sewer PVC pipes and thin HDPE pipes are used, but in this case, to create runners you need to use several pipes for each ski.

To make a sled you will need

From the tools:

- Bulgarian.

- Welding machine.

We recommend reading: 18 best winter ice caps

From materials:

- Pipes.

- Plates.

- Corners.

Materials and tools

Note. The choice of plywood in the end will still be yours, but we want to offer you the most suitable lumber. Below we will draw your attention to brands with sufficient strength and good moisture resistance.

We will make a model like the one in the photo ourselves

Plywood:

- At the moment, the most popular plywood that meets our requirements is the FSF brand. It has good strength, elasticity and wear resistance. This is very important, since the model we are constructing will be subject to serious mechanical loads;

- in addition, thanks to the phenol-formaldehyde resin glue with which the veneer is impregnated and glued, the material has excellent water resistance (FSF is used for roofing work);

- But for the FB brand, bakelite varnish is used, with which the veneer is impregnated, after which these sheets are fastened together with bakelite glue. Thanks to this impregnation, the material can be used not only indoors with high humidity, but also outdoors, since it is not afraid of precipitation, and in some cases such plywood is used even under water. In terms of mechanical strength and elasticity, FB is not inferior to FSF, but even surpasses it, and this, of course, increases its price;

- also in our case, the BS brand will be very good - this is the so-called aircraft plywood, which was previously used exclusively for the needs of aircraft and shipbuilding. For impregnation and gluing of veneer, alcohol-soluble bakelite glue is used here (not to be confused with the BV brand, where this glue is water-soluble). Therefore, the products have excellent water resistance. But this is perhaps the most durable plywood of all its analogues, because it is not without reason that airplanes were built from it, for example, the famous U-2, which became famous during the Second World War.

Note. The thickness of plywood for the sides and partitions is 20 mm, but for the lid on which they will sit, in our case it is better to use a 24 mm sheet, since we will cut it into slats. But if you make the lid from a single piece, then a thickness of 8-10 mm is sufficient.

Aluminum tape

Skids, fittings, tools:

- for runners, you definitely need to purchase a metal tape in a store (at a metal store). It can be steel, but it is best if it is duralumin - this is an aluminum alloy with additions of copper, manganese and magnesium and, with its softness and flexibility, it can withstand heavy loads (used in aircraft construction). The thickness of the strip will be 1-2 mm;

- Some parts you will need to attach with waterproof epoxy or solvent based glue, and in some places you will need self-tapping screws. You may also want to make a back, but you can also use a metal strip for this;

- The tools you will need are an electric jigsaw, a router and a screwdriver. But if you don’t have a router, you can process the edges with a rasp and sandpaper.

We choose quality material

The main material is plywood. The choice is always difficult. Each of us has probably encountered such a problem as delamination of plywood from the end part and asked the question, what causes this delamination?

Well, of course, this is mainly due to low-quality plywood. If this is not the first time you have picked up a jigsaw, then you can select plywood from the remnants of a previous craft. If you are new to sawing and you don’t have plywood, then buy it at a hardware store. Choosing material for sawing is always difficult.

You should always choose plywood carefully, often look at the defects of the wood (knots, cracks) and draw conclusions. The difficulty in choosing plywood lies in the fact that no matter how you guess at its defects and shelf life. For example, you bought plywood, cleaned it, translated the drawing and suddenly it began to delaminate. Of course, this has happened to almost everyone and it’s oh, how unpleasant. So it is better to pay attention when choosing and choose good plywood. I wrote a special Article in which all the principles of choosing plywood are described step by step.