Types of sleds

Sleighs can be divided into two groups. The first type of sleigh with high runners. Such sleds are best suited for overcoming loose snow. This type of sleigh is used by Father Frost and Santa Claus, because they have to overcome the most impassable snow.

The second group is with low runners. Such sleds are better suited for areas where the snow has already been trampled down. This type of sled is more maneuverable than one with high runners.

Nowadays, the choice of sleds in stores is simply huge. There is a choice not only in design, but also in the material from which they are made.

In the old days, people did not have the opportunity to buy them; they made sleighs with their own hands. The material for production was wood. They made sleds without nails, since metal used to be very expensive.

Today we will also disassemble and make a sleigh with our own hands. They can be made from pipes, wood, in general, anything you can find at home.

Manufacturing Features

In winter, when rivers and lakes freeze and you need to transport cargo off-road, you cannot do without a motorized towing vehicle. It is also called a “motor dog” because of the separate arrangement of the sled - the drag and the transport itself, reminiscent of the entire transport mechanism of a dog sled. What is a motorized towing vehicle? This is a towing vehicle coupled to a drag sleigh.

A drag is a cart made of two fastened poles, the front ends of which serve as shafts.

A snowmobile and a motorized towing vehicle are often confused. A snowmobile is mainly used for recreation in the mountains, hunting and fishing, and a motorized towing vehicle is designed to simplify the life of residents of the North, and not only that, it can become an indispensable assistant in large production or in agriculture. A motorized towing vehicle has a maximum speed of 40 km per hour, which cannot be said about snowmobiles, whose speed reaches 200 km per hour.

You can control the first one either while sitting on a trailer or standing on a sled.

It is also necessary to take into account the fact that the motorized dog does not have brakes. The difference between a snowmobile and a motorized towing vehicle is that the sleds for a snowmobile have an additional compartment where you can place a load , while the sleds of a motorized towing vehicle are standard or look more like a small plastic trough.

A huge advantage of a motorcycle towing vehicle is that the barrier fence or, in other words, the bump stop protects the driver and cargo from small stones, and the cross-country ability in deep snow is better than that of a snowmobile. He can't trample the snow that much.

This is interesting: FIRST AID FOR FROSTBITE.

And the cost of a motorized towing vehicle is less than the price of a snowmobile. But you need to take into account that the drags, although they are factory-made and made of a frost-resistant and durable plastic alloy, are still not as wear-resistant as metal. The drags are subject to wear, and even worse, they can be broken on stones or on asphalt when the snow melts.

Even if the snow has not started to melt, your vehicle can easily be damaged by any obstacles on the road.

Over time, the bolts may also loosen and weaken the connections of the entire mechanism. In this regard, you can also make your own sled for a motorized dog. When developing with your own hands, you should take into account all these points and make them for yourself.

One of the features of making homemade sleds is that they are made of plywood and metal profiled pipe. For ease of movement, a metal frame is specially installed on the runners so that the sled glides easier on the snow.

Structure

Before we get started, we need to understand how they work.

To do this, you need to find drawings of the structure of the sled on the Internet. After you have studied all the diagrams, you need to decide what size the sled will be and how you will use it. Read here - How to make a barrel with your own hands: drawings, projects and a step-by-step master class for building a barrel (105 photos)

It is known that to increase the stability of a sled, it is necessary to increase the distance between the runners. However, you should not forget about the roads on which you plan to travel.

Snowmobile sleds - types of structures and the principle of their operation

There are several main types of snowmobile sleds, and each has advantages and disadvantages . The sled is very versatile in its design. They easily attach to all types of snowmobiles. For example, for a Yamaha snowmobile, Russian Mechanics, Ermak, Viking 540, Dingo 150, BRP and Varyag 550.

In order to choose the type that suits you, you need to consider several factors:

- the routes and trails you need to navigate, features of snow cover and terrain;

- type of cargo transported;

- driving style.

For more information about snowmobile sleds, watch the video:

Volokushi - description and dimensions of plastic snowmobile sleds

Sleigh drags are the easiest option.

They have several advantages:

- compactness and low weight;

- simplicity and speed of loading and unloading luggage;

- The drag body body does not freeze.

However, drags have a serious drawback - due to the design features, their front part is often damaged. This type of sled is inexpensive, and making it yourself is impractical.

Passenger

rarely seen . They usually consist of a housing made of plastic or plywood mounted on skids.

For greater passenger comfort, the design of the passenger sleigh can be sprung, and lighting and heating can be installed in the cabin.

They are not easy to find on sale, but such designs are sometimes made by winter fishermen and other outdoor recreation enthusiasts during the cold season.

A passenger sleigh can carry one or even several passengers, therefore, having only one snowmobile, the owner of this design can take a large company out into the snowy nature.

The main disadvantages are the large dimensions and weight of the structure. Because of this, passenger sleds can only be attached to powerful, high-powered snowmobiles.

Freight

Cargo sleds are the most versatile and practical option. They are designed more complexly than drags, but at the same time much simpler than passenger ones. These sleds have a large load capacity with small dimensions.

Due to the relatively small contact area with the surface, cargo sleds have a smoother ride than drag sleds - such structures easily slide on their runners, easily overcoming obstacles.

The luggage in them is protected much better. Below are photos of a homemade snowmobile sled.

Due to the fact that their skis are located at a great distance from each other, cargo sleds can also boast much greater stability than drag sleds.

Every spring, plot owners sow various crops. Here you can get acquainted with the precision seeder.

Cultivators have become very popular among summer residents. By clicking on the link you will learn how to choose a cultivator for your garden.

To grind grain, a special device is used - a grain crusher. With the Cyclone grain crusher this can be done quickly and efficiently.

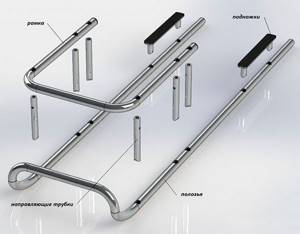

A standard cargo sled consists of three main elements:

The frame is the basis of the entire structure. The runners are attached to the bottom of the frame using racks. There is a flooring on top, on which the loads will be placed.

For greater convenience and functionality, the frame of the cargo trolley must be equipped with railings and a covered structure placed on it.

In such a box, cargo will be reliably protected from snow and wind.

Body

The body will be made in a rectangular shape. It needs to be covered with chipboard or plywood on the inside. The thickness of the covering material should be about 1 centimeter.

The frame itself can be made from ordinary pipe. The thickness of the pipe in this case should be about 2 centimeters.

You can use either a square or round shape. The thickness of the pipe metal must be at least 2 mm. The main parameters of the body will be approximately 2 m/2 m/0.3 m.

Manufacturing technology

Features of metal sleds

Metal sleds consist of the following elements:

- runners;

- seats;

- backrests;

- pusher handle (removable, which can be placed in front or behind);

- footrests

- handrails, etc.

The runners of metal sleds are usually made of steel, the seats are made of wood, the backs, armrests, handles and other parts are made of aluminum. Also, the runners can be flat or made of a pipe with thin walls (hollow pipe), from which the entire frame of the sled can also be made. Most modern models are equipped with seat belts, covers, couplings, rubber pads - for the convenience of the child sitting on the sled and the parent who is rolling the vehicle. Budget models have a strong rope instead of a handle. The standard set of materials includes a metal pipe, boards, decorative coating, rope, padding polyester for making accessories, etc.

Requirements for quality sleds

Despite the fact that at first glance the design of a classic sled may seem extremely simple, assembling the model involves many important points and nuances. Thus, a good sled must withstand weight up to 100 kg, be durable, lightweight, maneuverable and have minimal safety. Models should be designed for a wide age range of seated people. The type of materials for the frame also plays a role. For example, sleds with aluminum runners are more expensive; they glide well and are maneuverable, but may require repairs during active use.

Seasonality of the sled manufacturing business

Of course, the sled manufacturing business is seasonal. As a rule, it starts in early autumn and lasts until February-March. However, modern attempts are being made to solve this problem by expanding the range of products. For example, in a workshop equipped for mass production of sleds, you can assemble the same carts, wheelbarrows, garden swings, chairs on a metal frame, etc.

The main stages of the technological process of making sleds

| 1. Cutting pipes to size. | 2. Chamfering the ends of pipes. | 3. Pipe bending. |

| 4. Welding of metal structures. | 5. Cleaning of welds. | 6. Application of protective and aesthetic coatings. |

To complete all of the above stages, a standard set of professional machines and machines is required, which includes the following components:

- Disc cutting machine – proven equipment for cutting to size pipes with a diameter of up to 50 mm;

- The pipe facing tool is the optimal solution for removing chamfers and burrs from the ends of pipes. Such a tool copes with the removal of internal and external chamfers;

- A pipe bending machine is a professional machine designed for bending pipes. Modern equipment allows you to bend pipes at almost any angle, without losing the reliability of the metal workpiece;

- The welding machine is the optimal solution for semi-automatic welding of metal structures in a carbon dioxide environment. The set of welding equipment also includes a straight grinder, which will qualitatively process and clean the seams, preparing the product for assembly and painting.

When painting a sled, first a layer of primer is applied, and then a polymer paint, which is resistant to mechanical stress, moisture, temperature, etc.

Hitch

To soften possible shocks during braking or when driving, you need to add a spring to the hitch design. It will serve as a shock absorber. The hitch is also called a drawbar.

We will use the cross-section of the pipe as in the body: about 2 centimeters. With the help of a bushing you attach your hitch to the body.

Types of sleds produced

There are several types of sleds, here is a list of them:

- Ice sled . The best demand is for the so-called ice sleds, which cost about one hundred and fifty rubles. These sleds are equipped with side handles and a hand brake. They are very comfortable because of their backrest and that is why everyone buys them.

- Snowmobiles . In addition to plastic sleds, there is another variety of them, they are called snowmobiles. They differ from plastic sleds in that these sleds have a special steering wheel, as well as shock protection. This type of sled also has two seats and is made of plastic; these sleds simply have a large number of modifications. In essence, they are a sled, riding on which you can feel like you are on skis, since a person has a steering wheel. They cost about 1,500 rubles. If they are sold by any foreign company, they will cost twice as much.

- Sleigh and stroller . This sled is very similar to a regular stroller, and the only difference between it and a stroller is that instead of wheels there are runners. This sled has a very large number of modifications, it has a foot cover, a visor, and also safety belts. But besides this, they have one more property that most children do not like: they have a fixed seat position, that is, it will not be possible to unfold this sled like a regular stroller and go anywhere with it. They are only suitable for walking.

Skis

Now the most important thing you won’t leave without is skis. You need to take sheet metal. You can also use wood and plastic for skis. Measure the length that suits you and cut the skis. Their length should be slightly longer than the length of the body.

The skis are secured to the body itself with racks. The height of such a stand should be about 13-15 centimeters. It itself is shaped like the letter P, and there should be 8 of them.

Do-it-yourself sewing machine repair: rules for operating a sewing machine. Problems with sewing machines and step-by-step instructions on how to fix them yourself

DIY sewing machine: primitive models and tips on how to build a machine (100 photos and videos)

How to make a crossbow with your own hands: step-by-step description of making small arms (video + 95 photos)

How to make a snowmobile sled with your own hands?

First, you need to draw a sketch or diagram of the future structure. Snowmobile sled drawings should include elements such as:

- body;

- frame;

- drawbar.

In addition, you should draw a picture of the skis, indicate their location and the placement of fasteners. This way you will know in advance what exactly you will get in the end. In addition, by calculating the length and width of the structure, you can find out exactly what quantity and length of metal you need for the work. But here you need to be careful, since the data does not always coincide with reality. For this reason, you should buy a little more sheet metal and other steel products (at a rate of about 8-10 percent more than required). For example, if for work you need to purchase a pipe with a square cross-section 200 centimeters long, add 10% to this value and get data of 220 centimeters. In any case, this “tail” can be trimmed. It’s another matter if the pipe turns out to be short - this is where the problems begin.

For fishing

A young fisherman can be distinguished from an experienced one by one characteristic. An experienced person always has a huge number of devices and accessories for fishing.

One of these is a fishing sled. Let's look at how you can make them yourself.

To make it, we need a drill, boards, preferably pine, sandpaper, a jigsaw and glue.

The boards will serve as runners. We cut out semicircles on them. We cut out sheets of metal and attach them to runner boards to improve sliding.

To connect the runners, we attach bars on top. We install several boards on top so that we have a base and seats for the fisherman. After all, many people go hunting for more than one day, and such sitting will be very useful.

Do-it-yourself grain crusher: types, principles of operation and tips on how and what to make an effective crusher from (85 photos)

Do-it-yourself ski mount: installation and tips on how to install various types of mounts correctly (115 photos and videos)

How to make a castle with your own hands: building decorative medieval castles and fortresses (110 photos)

The boards should be varnished so that they do not become unusable so quickly.

Sleds for fishing are not very large in size. Therefore, they can be made from many things that are no longer needed at home. For example, modernize old metal bathtubs.

There are many diagrams, photos and videos on the Internet on how to make a sled with your own hands. The manufacturing technique is approximately the same for everyone. Just a more modernized version somewhere.

It is worth remembering that any sled after its manufacture must be tested for professional suitability. Do a home run-in.

We hope this material was useful to you and no snow will be an obstacle for you.

How to make skis with your own hands: choice of materials and technology for making skis at home (105 photos and videos)

DIY cockroach trap: options, effective ideas! Operating principle of cockroach traps, types - glue, ultrasonic, electric, electrostatic, poisonous

How to make a furnace for mining: drawings, operating principles and construction of simple and effective furnaces (video + photo)

What to make it from?

If the material itself does not raise any questions, then there are still many unclear issues regarding the shape, length, thickness and type of wood, which will be sorted out in this article.

It is best to purchase ready-made small boards of processed wood, but if it is not possible to purchase them, then you can cut them out of wood yourself using a woodworking machine. To process wood you will also need a sander, a jigsaw and a drill.

In addition to a block of wood, you will also need metal strips; aluminum strips are best suited for sleds.

For drawings and making various marks, you will need to take a standard student set: ruler, pencil and paper.

Wooden tenons, screws, round cross members, and glue are small but important parts that cannot be used to assemble a children's wooden sled.

DIY sleigh photo

Help the site, repost

0

Is it profitable to make children's sleds with your own hands?

Almost anyone can make a children's sled - you don't need a large room for this. An analysis of the forums where this area of activity was discussed shows that a personal garage was enough for aspiring entrepreneurs. Numerous publications on the topic of “do-it-yourself sleds” also speak in favor of this approach. You can find everything in them: detailed drawings, video tutorials, useful technological techniques, even calculations of costs and profitability. At the same time, people agree that the production of sleds is a seasonal business and is unlikely to be able to pave the way to the Forbes list. Although there will certainly be a good and stable additional income from this business.

“I’ve been in this business for 7 years, I know a thing or two. I’ll tell you about myself: in the summer I work in the field, in the winter in the garage,” writes @makar1984. “There’s a lot that can be done, but in my town with a population of 60 thousand souls, on average only 15 sleds are sold a week. Somewhere from mid-November to early February I sell 100-120 pieces. Not more. The profit is about 500 rubles per sled. So judge whether you will become a millionaire.”

This post was commented on by Igor Malyugin, a small business expert. “The numbers are true,” the expert said. – There is data from sociologists: in a city with a population of 100 thousand people, they buy 400 sleds per year, plus or minus 100, depending on the economic situation in the region. For those who work mainly in the summer, this idea will indeed be useful - however, if there are no entrepreneurs in the city who have been making and successfully selling sleds for several years. Otherwise you won’t earn much yourself, and you won’t give it to anyone else.”

Sources

- https://o-krohe.ru/pokupki/zimnie-tovary/derevyannye-sanki/

- https://realybiz.ru/idei/biznes-ideya-proizvodstva-sanok

- https://www.openbusiness.ru/biz/business/svoy-biznes-proizvodstvo-sanok/

- https://arsenalmastera.ru/goods/Sani-i-sanki-fotoobzor

- https://www.rezka-trub.ru/technology/tehnologiya-izgotovleniya-sanok/

- https://www.equipnet.ru/org-biz/biznes-na-domu/biznes-na-domu_351.html

[collapse]

Cargo homemade sleds for snowmobiles

A special feature of cargo sleds is their resistance to heavy loads. This is achieved by using durable materials, such as metal. Skis are made wide. Due to this, the runners do not fall into the snow. Improves maneuverability and stability when the snowmobile moves at high speed. Shock absorbers are sometimes provided between the runners and the platform frame. They smooth out impacts on bumps. The sled bounces less, which reduces the likelihood of damage or loss of cargo.

Shock absorbers smooth out impacts when riding a snowmobile on uneven terrain, thereby improving cargo safety

READ ALSO: Sealing PVC sewer pipes with epoxy resin, Connecting a cast iron pipe with a plastic one without dismantling it yourself, Sealing tape

The snowmobile sleds shown in the photo are made from metal with your own hands. The platform is covered with plywood. The sides are welded from tubes. They won't interfere with cargo sleds. It is convenient to secure the transported cargo with straps over the sides.