Silicone molds have recently become extremely popular. Universal silicone transparent sealant for exterior use? They are made very simply. If desired, you can even make them yourself. Their service life is very long compared, for example, with gypsum.

However, of course, a high-quality mold can only be made from a material with good performance characteristics. What qualities should liquid silicone for molds have and what should you pay attention to when purchasing it?

Types of silicone and master models

Of course, when purchasing material for making molds, you should first of all pay attention to its technical characteristics. Today, only two main types of silicone are produced: coating and filling.

For both materials, master models made of metal and wood, as well as plastic, cardboard, or even just paper can be used in the manufacture of forms.

Potting silicone

It is also a good material for making molds. When using it, the master model is installed in the flask and poured from above. Liquid silicone for molds of this variety consists of two components: a hardener and a base.

Before pouring, they are thoroughly mixed and then placed in a vacuum chamber to remove air bubbles. A very popular material of this type is, for example, “Pentelast-708S”.

Where to buy and what is the price in Moscow of liquid silicone for making molds

Liquid silicone for molds is cured with a platinum or tin catalyst, which determines its final characteristics. The material, which is vulcanized with tin, is quite strong, withstands tearing and stretching well, is circulation-resistant and durable, has a different range of hardnesses, and practically zero shrinkage. As a rule, it is used on an industrial scale. The catalog of our online store presents Flexilis

Tin catalytic with base color "

S

" series white. It can be painted with organic dyes and has a wide range of applications: the production of souvenirs, soap, candles, shoe soles, decor, and accessories. Translucent silicones with platinum also have all the advantages of tin compounds: high strength, inert to aggressive environments, have different viscosities, and evenly fill small relief details of the model being copied.

Silicones Flexilis

- These are high-quality compounds that are quick and easy to work with.

They contain a 50/50 proportion of components A (silicone rubber) and B (catalyst), which are mixed into a homogeneous mixture during the manufacture of molds, then a polyaddition reaction occurs. Master molds for casting can withstand repeated removal from finished products. Adhesion to almost all materials makes it possible not to use release agents. buy liquid silicone for making Flexilis

with platinum and tin catalyst-hardeners at a competitive price at. Order delivery is carried out throughout Russia.

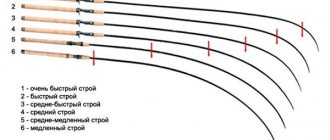

Elongation factor

What characteristics can be considered the most important when choosing a material such as liquid silicone ? In principle, almost any variety of it is suitable for making molds. However, it is still worth paying attention to some indicators when purchasing. The most important parameter characterizing the quality of silicone is the elongation coefficient.

For modern materials this figure ranges from about 200-1300%. The higher this number, the more the hardened silicone can stretch and the greater the number of castings a mold made from it can withstand.

In practice, 700-800 percent one- or two-component liquid silicone is usually used. It is usually ideal for mold production. Products made from material with this elongation coefficient can easily withstand up to 80 castings.

This figure may be smaller or larger, depending on the complexity of the master model configuration.

How to choose the right silicone? 01/18/2019 10:26

You have decided to make a mold and don’t know where to start, then this article is for you. Two-component liquid silicones are intended for making molds and then pouring various materials into them. Also, silicones can be used to make products such as masks, dolls, gaskets, phone cases and much more. The range of silicones is quite large, as is their application. Now we will tell you in more detail what you need to pay attention to when choosing silicone.

Main characteristics of silicone:

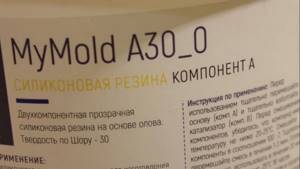

Liquid silicone for molds consists of two components: the bulk and the hardener (catalyst). The bulk begins to solidify only when a catalyst is added to it; until this moment it is in a liquid state. There are two types of catalysts: tin-based and platinum-based:

- “Tin silicones” are characterized by low cost and shrinkage. Such silicones have a short lifespan, which is especially shortened when an aggressive medium is poured into them (liquid plastic, polyester resins, etc.). Over time, the form becomes more fragile and shrinks. Silicone is suitable for pouring plaster, polyurethane, resins, paraffin, wax and liquid plastic. To increase lifespan, we suggest using silicone grease.

- Silicones on a platinum catalyst

more expensive and non-shrinking. Designed for longer use and are heat resistant. And the main advantage is the ability to use it in the food industry.

Main differences:

| Non-shrink material, some have small shrinkage less than 0.2% | No shrinkage |

| The service life of the mold depends on the number of castings and the material being poured, for example, gypsum is about 1000 castings, liquid plastic is 30-100. Mold Max silicone has higher figures: 3000 castings from plaster, and about 200-300 from plastic. | The service life also depends on the number of castings and material, but the replicability of such silicones is several times higher than that of “tin” silicones. |

| Not resistant to sulfur-containing materials | Not resistant to sulfur-containing materials |

| You can speed up hardening by adding more catalyst or applying slight heat. | You can speed up hardening by heating. |

| less expensive | Use in the food industry and cinematography (creating molds or masks, safe in contact with skin) |

Hardness

The Shore scale is used to measure the hardness of silicone. Most often, silicones range from 10 to 40 Shore. The smaller the blinkers, the softer and more elastic the shape. To create small forms with complex textures, softer silicone is used, and for large forms with texture, harder ones.

Lifetime

Pot life is the time at which silicone remains liquid. The more catalyst you add (for tin silicones), the more the lifetime will decrease. Also, most often, the higher the hardness of the silicone, the shorter its lifetime. Manufacturers usually indicate the “ideal time” of 25-30 minutes (this time is under ideal conditions: a certain temperature, precise weighing of components, etc.), we advise (depending on the hardness and catalyst) to have time to mix and pour the silicone within 7-15 minutes .

Viscosity

More fluid silicone has a lower viscosity value. The lower the viscosity, the easier it will be for you to work with silicone, but usually these are silicones with low hardness.

Tear strength

This characteristic is important for the production of parts that will subsequently be subject to load.

Color

Color is used not only for uniform mixing of silicone, but also for recognition of your particular shapes. Very often, manufacturers add color to either component A or component B. We also sell special tinting pastes for polymer materials that will help you obtain colored forms.

Inhibitors

The curing reaction can be greatly affected by various materials (inhibitors):

Application of silicones

| For what? | What kind of silicone? |

| Candles and soap | Alcorsil and Super Mold |

| Scrapbooking | Super Mold M10, Alcorsil 315, Mold Star 15. |

| For making makeup, masks, dolls | Ecoflex and Dragon Skin |

| Gypsum | Alcorsil, Super Mold, Mold Max |

| Food industry | Elastolux platinum |

Silicone viscosity

This is also an important indicator that has a huge impact on the quality of the finished form. Pouring liquid silicone for molds has a very low viscosity. During operation, it easily fills the smallest recesses of the master model.

Therefore, it is advisable to use it for the manufacture of molds of very complex configurations.

Viscosity is measured in CPS. For potting materials this figure usually does not exceed 3000 CPS. For comparison: water has a viscosity of 0 CPS, sunflower oil - 500, honey - 10,000.

Other indicators

In addition to viscosity and elongation coefficient, when choosing silicone you should pay attention to:

Work time. The higher this indicator, the longer the material retains its viscosity.

Polymerization time. This characteristic is also quite important. It shows how long it takes for the poured form to reach the stated elongation factor.

Two-component liquid silicone for mold making typically takes longer to harden and polymerize than it does when viscous. This can be attributed to the advantages of the material. After all, when working with it, the master does not need to rush anywhere.

How to use

Liquid silicone is used to make molds as follows.

The master model is fixed to the stand with a drop of superglue and coated with a special release agent. At home, this could be, for example, Vaseline or machine oil.

The stand with the model is fixed in the flask. The latter can be made from almost any material: wood, plasticine, plastic, etc. Universal silicone sealant for sewer pipes? Disposable flasks are made of paper. Its height should be twice that of the future form.

The fact is that during the vacuumization process, silicone foams very much. One of the walls of the flask must be removable.

The evacuated compound is poured into the flask in a thin stream. This is necessary to ensure that as little air as possible gets into the liquid material.

The flask is placed in a vacuum installation for 1-2 minutes. Repeated processing is necessary in order to remove absolutely all the air from the silicone that got into it during pouring.

The form hardens in about 5-6 hours. The final polymerization occurs after a day or three. At the final stage, the mold is removed from the flask and cut in half.

After this, the master model is removed from it.

The process of making silicone baits with your own hands

- First of all, you need to melt the silicone. To do this, for example, the old parts of the nozzles are put into a container and melted (over an open fire or in the microwave) or immediately put into a syringe and sent to the microwave. The first case is convenient when several people are involved in the process and a large amount of material is melted, or there are Several prints available.

- In the second case, the syringe should be filled with waste , close the nose of the syringe and put it in the microwave. The beauty of this method is that there is no fumes.

Color of future bait

The color of the future bait depends on the wishes of each fisherman. You can melt baits of the same color together, you can mix them - then the color will change. When using ready-made silicone, you can add dye and glitter, for example, from Glitter. They are applied as the first layer to the matrix. Food coloring of any color is mixed with the material and sent to the print.

Taste of bait

To increase the number of bites and improve fishing results, the bait can also be given taste. To do this, during the manufacture of bait, you can add salt, fish oil, attractant, and flavoring.

It is worth remembering that if the bait is impregnated with an attractant after its manufacture, it loses its properties after the next fishing. You need to additionally coat the bait with flavoring after fishing. This is done in this order: the used product must be washed, dried, placed in a bag and an attractant or flavoring agent dripped inside. Stir and leave for 3 days in a dark and dry place.

Form fills

Having melted the silicone, pour it into the prepared mold. If a one-sided mold is used, then pour our product on top, wait a few minutes and remove the finished bait from the print.

The casting process for double-sided prints is slightly different. Here two halves are used, which must be connected to each other. Then, hot material is poured into the impression injection channel until the die is completely filled. Hold the matrix at an angle.

Removing the bait from the mold

After hardening (about 5 minutes), the rubber products are removed from the molds and sent to a container with water, where you can add ice until it cools completely.

Trimming the shape

If necessary, ready-made nozzles must be freed from excess silicone: we cut off the excess with scissors, making the product completely similar to the used sample.

Liquid silicone for molds: price

The advantages of this material include not only the ease of making molds. It has earned great popularity due to its low cost. The price of high-quality silicone can range from only 450-750 rubles.

In specialized stores or on the Internet, you should look for silicone intended specifically for making molds. The fact is that today a variety of types of this material are produced. For example, liquid fishing silicone is sold.

It is used to lubricate braided threads on gear, which extends their service life and increases casting distance. Such silicone, of course, is not suitable for making molds.

Application

We somehow smoothly moved on to the fact that homemade molds are made from silicone, but this is not entirely true. You can use various materials to create molds. But if we consider the process from the point of view of practicality and quality, then silicone is the best material for molds and this will be proven below in the text. As general information, we note that such molds can be used not only for pouring epoxy resin.

- The cavities are filled with mastic, clay or plaster.

- Silicone is harmless in contact with food, so it is used in cooking.

- Molds are widely used in the production of candles or soap at home.

The two-component silicone used is highly heat resistant. It is non-toxic neither in liquid nor in solidified state, that is, the silicone mold can be placed in the oven for baking. The cost of ready-made molds depends on their number in the set, as well as their size. On average, the price for a set starts at 300 rubles.

At first glance, it may seem that it is simply impossible to make complex prints on your own, but the algorithm of work is quite accessible even to those who do not have the proper experience. Experienced craftsmen don’t even try to look for the necessary molds on the Internet, but immediately start making them. Some even managed to start a profitable business from this.

Useful to know > How can you clean epoxy resin, what solvents help

It is important to understand that an opened package of silicone will not allow it to be stored for a long time. It will remain usable for about a month on average. Therefore, it is recommended to make plans for the future and fill several molds at once, which may be useful later.

How to make at home

In order to make liquid silicone for molds with your own hands, you need to buy ethyl alcohol and liquid glass. You will also need a plastic bottle and a wooden stick. Since silicone components are quite caustic materials, you should wear thick rubber gloves on your hands. The manufacturing procedure itself is as follows:

Liquid glass and ethyl alcohol are poured into a plastic bottle in equal parts.

The mixture is thoroughly mixed with a wooden stick.

After it thickens, it needs to be removed from the bottle and thoroughly kneaded with your hands.

Silicone prepared in this way resembles plastic, sticky rubber and can be made into any shape.

Collapsible silicone mold for DIY casting

Greetings, Samodelkins!

Today we will create a complex silicone mold for reusable castings.

To do this, you will have to dive into some interesting subtleties. Taking impressions opens up enormous opportunities for all kinds of homemade products. Usually, to make a cast of a figure, you need to make two halves. One half is covered with sculptural plasticine, and the second is filled with silicone.

Then remove the plasticine and pour silicone into the free half again. This way you can make impressions of excellent quality.

But what to do if the entire figure is made of sculptural plasticine.

No, it’s not a tree, not a mushroom, or even broccoli. This is a model of an atomic explosion from the largest bomb in human history, AN602.

The author tried to make this model more or less similar in shape to that very explosion. We will make a cast of it. To then cast it from epoxy.

Everyone loves explosions and it's nice to have such a small glowing atomic explosion on your desk.

Materials and tools:

1. Silicone 2. Vaseline 3. A couple of boards 4. Screwdriver and screws 5. Knife 6. Pliers 7. Plastic caps 8. Sculpture plasticine

When taking an impression, it is very important to think about how the model will be positioned, so that when pouring silicone it does not turn out to be unable to fill some areas. Or in the future, when you pour plastic, epoxy, gypsum, wax or anything else into the mold, there should also not be a place where air cavities may appear, into which the composition simply cannot enter.

For this purpose, the author bought a bucket of cheap Chinese silicone and, probably, this is the cheapest silicone that exists. Hardness thirty. That is, it seems like medium hardness. Just what you need for collapsible forms.

The layer of silicone around the figure should be at least two and a half centimeters.

You'll have to make a box of the right size.

All seams must be covered with plasticine, otherwise it will leak.

The silicone won't leak much, but it's still unpleasant. At the top the model is much narrower than at the base. You can’t leave it like this, otherwise a whole kilogram of precious silicone will be lost. Therefore, the filling had to be made from the bars. Unused corners and nooks and crannies can also be covered with plasticine to save money.

To make it easier to peel the silicone from the wood, all walls must be thoroughly treated with Vaseline. Where would we be without him?

In order to secure the model inside the formwork we will use self-tapping screws. The plasticine is sculptural, not very soft and holds its shape well. So, in principle, it should work. In order to know to what height to fill and not guess later whether you poured a lot or a little, you need to roughly mark the desired level with a pencil.

And now there's silicone. It comes with a tin hardener, and sometimes with a platinum hardener. Tin is naturally cheaper and more unpretentious.

There are rumors that silicone does not interact well with plasticine and may not polymerize. In this case, the plasticine begins to melt and the model can then be thrown away. To save yourself the hassle and not worry about this, just pour a little silicone into a mold made of the same plasticine as your model. After some time, see what happens. Most likely everything will be fine and there will be no mistakes.

If the silicone does not want to harden, then you need to cover the plasticine with a layer of Vaseline. Or, as an option, purchase special aerosol separators. They are sold in the same place where silicone is sold.

Having estimated the required volume of silicone, taking into account the fact that it will also spread throughout the container when stirred, the author decided to prepare one and a half kilos. When mixing with the hardener, you need to mix very carefully, by hand, so as not to create bubbles in the silicone. Usually, even if bubbles appear, they basically come out of the mixture well. But not in our case. Chinese silicone snatches air just like before death. Even with gentle stirring, there are a bunch of bubbles inside. The author tried to do degassing using a small vacuum pump.

Now you need to make the locks. The form will be collapsible, which means it must fit together clearly. The author suggests using these plastic caps.

Plastic is lighter than silicone, but not by much. You need to experiment before pouring. Mix a little silicone and choose something suitable that will not sink completely and will be easy to remove. We press plasticine inside the caps to make them heavier.

But not so much that they sink completely, but so that they stick out slightly from the silicone. You need to place such locks as often as possible. There won't be any extra ones - that's for sure.

After the silicone has completely hardened, you can pull out the caps and cut off any protruding burrs.

When pouring the second half, silicone will be poured into the resulting recesses and you will get locks that will help to accurately join the two halves.

Next, lubricate the surface of the silicone with Vaseline so that the next layer does not stick to it. We finally close the formwork with the last board. Then pour silicone to the mark that you previously marked with a pencil.

In order for the silicone to better wet the model and release gases, you can lightly vibrate it with a spoon.

Now you need to wait for the second half to completely harden. This should take about 16 hours at room temperature. In general, this particular silicone sets within an hour, but it gains full hardness in almost a day.

The silicone remaining in the container polymerized, but not completely. As usual, it is not possible to mix the silicone with the hardener well at the bottom and in the corners. It remains forever a sticky mess.

Therefore, it is better to use disposable utensils for kneading. Or the one you don’t feel sorry for. But if you happen to mix silicone in the favorite cup of your mother, wife, or God forbid mother-in-law, then you will definitely have to wash it. Basically, just like your hands. Regular soap, to be honest, does a terrible job. More precisely, it does not wash off silicone from your hands at all. Most silicone from dishes and hands can be wiped off with rags. And hand cleaning paste works well with the remaining silicone.

This paste is something like concentrated soap mixed with a fine abrasive. It scrapes off all the silicone and prevents it from sticking again. After wiping with the cleaning paste, simply rinse off all the silicone with water. And no solvents or other cleaning agents are needed.

Well, you can disassemble this miracle box. Any excess protruding pieces are immediately cut off. You can see how the silicone leaked through a small gap.

Even after smearing with Vaseline, the pieces of wood do not want to come off. You have to make an effort to separate the silicone. The halves stuck together quite strongly, but they were still served. Plasticine, even without Vaseline treatment, does not stick to silicone at all. The model turned out to be absolutely undamaged. Except for minor mechanical issues that are easy to fix. This method of making copies turned out to be very gentle.

They fit together perfectly. The joint line is practically invisible. Even when pressed, the two halves move as one. It's as if there is no connection at all.

The author deliberately left the sides flat to make it more convenient to fix the two halves before pouring, pressing them on both sides with two pieces of board. You don't need to squeeze it too hard, but you should at least hold it lightly. Epoxy tends to leak through any cracks. So we'll see how she behaves.

Thank you for attention. See you again!

Video clip:

Source

Become the author of the site, publish your own articles, descriptions of homemade products and pay for the text. Read more here.

Silicone molds for the oven

Of course, environmentally unsafe materials cannot be used to make such castings. In this case, liquid silicone for molds is made a little differently:

Three tablespoons of potato starch are poured into a yogurt cup.

Pour silicone sealant there in the same quantity.

Mix everything for ten minutes.

From silicone prepared in this way, you can easily make a simple baking dish. Before pouring the dough, it must be coated with vegetable oil.