Experienced fishermen who use spoons (including homemade ones) to catch fish can talk about frequent cases of them breaking due to hooks. After all, as a rule, there is only one option in this case: grab the line as close to the spoon as possible and pull it until it comes off, which naturally leads to the loss of the spoon. And it can be very disappointing if the lost lure was made with your own hands at home and had good “catchability”. In order to reduce the percentage of lost spinners, you need to slightly improve their design as described and shown on the drawing of a homemade spinner below.

Read more about oscillating spoons at the link

There are several ways to make loaded spinners. The simplest is to add lead to the inside of the petal. But the spinner has an untidy appearance. It is better to cast spinners in special molds. For this purpose, gypsum, cement, graphite (the inner surface of the latter is metalized with copper), and metal forms are used.

Materials for making spinners

For the manufacture of spinners, sheet metal with a thickness of 0.5-3.5 mm is most often used.

The best metal for making spinners is copper and its alloys: brass, tempah (golden color) and cupronickel (silver-white color). Tombak and cupronickel are especially good.

In addition, a bimetal, which is soft iron coated with a layer of copper, or less often tin and zinc, can be successfully used.

Elastic grades of stainless steel are less suitable. Soft varieties are quite acceptable, but require processing. At an annealing temperature of 200-250° C, stainless steel acquires quite a variety of colors.

Aluminum and its alloys are unsuitable materials due to their lightness.

For casting spinners, it is most advantageous to use lead, adding tin or zinc to it if necessary. Lead is first poured into the mold, and then, when the lead has cooled, tin is poured, or vice versa. To increase the strength of the junction, the mold is additionally heated to the melting temperature of lead. Since lead spoons fade quickly, there are the following methods for finishing their surface.

The easiest way is to paint the lure “gold” or “silver” using the so-called “serebryanka”. There are sets on sale with varnish and bags of bronze or aluminum powder; After painting, it is advisable to sprinkle the spoon with mica crumbs.

Another method is galvanic tinning with the composition (in grams per liter of water): tin sulfate - 40-60 g/l, sulfuric acid - 45-90 g/l. First, tin sulfate is diluted in acidified water, and then the remaining acid is added. Treatment is carried out at room temperature of the solution. Power: coin cell or two coin cell batteries for flashlight; plus - tin plate, minus - bait.

There are other methods for finishing the surface of spinners.

Spinner thickness

The thickness of the spoon is closely related to its size and purpose. The thicker the spoon, the less mobile it is and vice versa. Thin spinners have easy mobility, while thick oscillating ones have good, stable movement.

The division of spinners into light, medium and heavy is determined by the degree of their mobility, depending on the thickness and regardless of their weight.

As a general rule, it is recommended to make spinners from thin sheet metal, ranging from 0.5 to 1.2 mm, and oscillating ones from thick metal, ranging from 1.2 to 3 mm.

As already mentioned, the thickness of the spoon is closely related to its size and stamping shape. Therefore, although changing the thickness is acceptable, it must be approached with great caution, since with a change in the thickness of the spoon, the nature of its play also changes.

It is not recommended to use spinners with a thickness of less than 0.5 mm, since very thin spinners, especially small ones, work unreliably and often “stick”, that is, they do not give play, and large and thin ones flutter a lot when casting. Likewise, small but thick spoons perform poorly, while large and thick ones will be too heavy to cast.

If it is necessary to have spinners weighing 40-45 g, their thickness should be in the range of 2.2-2.3 mm. It is best to take the thickness of the spinners according to a well-tested sample. If you have a good sample of a spoon and it is desirable to build the same spoon, but of a larger or smaller size, then their thickness should be taken in direct proportion to the area, i.e., how many times the area of one spoon is smaller than the other, the same number of times its thickness should be be smaller. In the case of using dissimilar materials, an amendment is made to the thickness of the spoon: by how many times the specific gravity of one metal is less than the other, the thickness of the spoon should be greater by the same amount and vice versa. If this rule is not followed, the spinners will differ in the degree of ease of their play.

The procedure for making a homemade spinner with your own hands

From a large oscillating spoon, it is necessary to remove the winding ring connecting the spoon to the tee. Using a line of smaller diameter than the main line, tie the tee to the second winding ring. Attach the forend of the tee with soft copper wire (0.4-0.7 mm in diameter) to the spoon through the lower hole for the winding ring. Cut off the excess ends of the wire and separate them a little. The specified fastening will not affect the play of the spinner and will reliably ensure the integrity of the “tee-spoon” structure during casting and small efforts when hooking onto small and not very strong obstacles on the bottom, and at the same time, in the case of a “dead” hook, it will allow you to preserve the spinner, having lost only the tee.

You can read more about the equipment of spinners in the material “Equipment of scaffolds”

Recommendations for choosing the diameter of the main line and leader:

| Characteristic | Spinning reel type | Fish caught | ||

| pike | zander | perch | ||

| Line diameter, mm: main (leash) | Inertial Inertialess | 0,6-0,7 (0,5) 0,4-0,5 (0,35) | 0,5-0,6 (0,4) 0,4-0,5 (0,35) | 0,35-0,4 (0,3) 0,3-0,35 (0,25) |

| Lowest breaking load of fishing line, kg: | ||||

| basic (leash) | Inertial Inertialess | 10.5 (7.5) 5,3 (4,0) | 7,5 (5,3) 5,3 (4,0) | 4.0 (3.0) 3.0 (2.1) |

When using fishing lines and leashes according to this table, the safety margin of the main fishing line compared to the leash is on average 25-30%. This is quite enough to prevent the loss of the spinner when hooked, losing only the tee.

What are spinners?

Spinner is the most catchy and easy to use bait. Oscillators have different sizes, shapes, and colors. Each option also has its own vibration frequency.

The spoon is the oldest bait with which you can catch predatory fish. Experienced fishermen observed how crucian carp or perch behave in the water. Oscillating spoons convey these movements of fish in the water.

It is necessary to add game elements to fishing - create movements that attract prey. Recreate the fluttering sounds of a wounded fish or one that is very frightened and is trying to swim away from a dangerous area as quickly as possible.

Lately, fishermen have been buying “wobblers” and forgetting about the main thing - our ancestors used to fish with spoons and did it successfully. They have been used for centuries. Unfortunately, this type of bait is undeservedly fading into the background.

But oscillators are still often used and they could not be replaced by modern purchased devices.

Homemade babbitt spinners

It is problematic to stamp spinning lures at home; for this, at a minimum, you will need a press. Cast lead spoons are less complicated to manufacture, but require galvanic coating with copper or other metal to create the necessary rigidity, which is also impossible without the appropriate equipment. In addition, such spinners are heavier than factory ones and therefore unsuitable for light spinning reels.

However, at home you can make simple cast homemade spoons from babbitt - an anti-friction alloy based on tin or lead, intended for use in sliding bearings. Babbitt spinners are cast in the same way as those made from lead, and the model is taken from a factory spinner or a plasticine imitation of any design. The mold for casting the spinner is made of gypsum (withstands up to 50 castings) or cement (M400-M600, withstands several hundred castings). The surface of the finished product requires only minor processing and sanding.

How to make a homemade spinner from babbitt

- Take (or glue) a cardboard box 6-7 cm high (the dimensions of the box should exceed the dimensions of the model by 1-2 cm).

- Fill the box halfway with a solution of gypsum or cement (the consistency of sour cream).

- Cover the model with a thin layer of Vaseline and carefully lower it into the solution so that it lies at the same distance from the edges of the box (in a factory lure, you must first cover the holes with plasticine). Lightly tap the box until the model is immersed in the solution to the desired depth.

- After the solution has partially hardened (25-35 minutes for gypsum and 24 hours for cement), remove any streaks of solution from the surface of the model.

- After complete hardening (after 2 hours for gypsum or 3 days for cement), grease the upper surface of the mold and model with a thin layer of Vaseline, then pour a new portion of the solution to the top of the box.

- After the solution has completely hardened, divide the mold, remove the model, and use a file to make a channel for casting (sprue) and air outlet in each half.

- Dry the mold well (7-10 days), otherwise during casting the process of vaporization and eruption of metal through the sprue may begin.

- Melt the babbitt in a container with a narrow “spout” (in an aluminum tablespoon), remove carbon deposits during the melting process and lighten the surface by periodically adding powdered ammonia. Try to avoid overburning the babbitt (pronounced blue color of the melt), which makes the product brittle. It is preferable to use Babbitt-83, which contains 83% pure tin, which does not tarnish and always has a silver tint.

- Pour the melt into the mold, shaking it slightly so that the babbitt spreads evenly, and remove the finished spoons after cooling. In the resulting castings, drill holes for the winding rings. Smooth out any unevenness on the cast spoon with sandpaper or a file.

Spoons made in this way usually do not require silvering, but if the homemade spoon is dark in color, it can be silvered.

You can get a silver spinner if you immediately pour melted babbitt into the mold. If you keep it on the fire a little longer, it will become golden in color, and the spinner will take on this shade. Keep it on the fire even longer and you will see the babbitt turn blue; the spinner will be of a bluish-olive tone. This type of lure does not require a sinker; it can be quietly cast “under the nose” of a perch or pike.

Oscillating spoon "Leningradka"

According to the dimensions indicated in the figure, cut a blank from sheet metal 3 mm thick, make two figured cutouts A and B with a depth of up to 4 mm in it. After this, stepping back 20 mm from the head part, use an emery wheel to grind the workpiece along its entire remaining surface so that its thickness towards the tail part reaches 1 mm. Next, bend the workpiece as shown in the figure, equip it with winding rings and a hook.

In addition to the holes in the head and tail parts, you need to punch a hole in the protrusion of the upper figured cutout (the diameter of all holes is 1.5-2 mm). It happens that it is useful to equip the spoon with an additional hook - then it is attached to the figured cutout.

For fishing at a depth of 1.5-2 m, the assembled weight of the spoon should not exceed 32-36 g.

Thanks to the bending of the spoon and the shift of the center of gravity to its head, the play of such a bait attracts a predator. If you attach red hairs to the tee and in the hole of the upper figured cutout, they prevent the spoon from quickly sinking to the bottom, which allows you to move the spoon slowly at the desired depth.

Metal tube spoon

An interesting option, which is the fastest of all listed in terms of time. Such spoons are made in two variations.

Option #1. We cut the metal tube of the required diameter at different angles. We process and polish the future lure. Drill two holes from different ends. One for attaching a fishing line or leash, the second for attaching a tee.

Option #2. The same principle, but there are several tubes that are connected through winding rings. The result is a composite spinner, like a mandula. The bends of such a spoon make it almost indistinguishable from the movements of a live fish.

Good homemade spoon

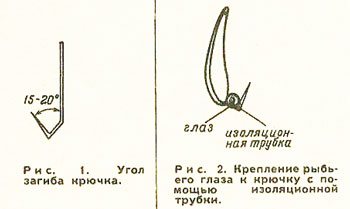

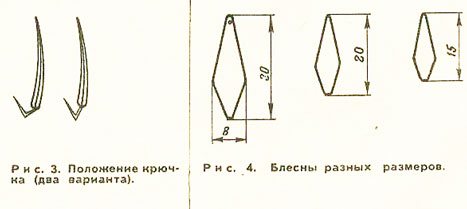

V. Sadikov offered the following homemade spoon. What’s new about it is not so much the lure as the hook (it’s homemade, there are no such things on sale). It is made from a needle or steel wire.

A hook of this configuration (Fig. 1) is unnoticeable and tenacious. The spoon is easily grabbed by fish. Placed on a hook and pressed with an insulating tube (Fig. 2), the fish eye film is hardly noticeable and does not interfere with the play of the spinner. The hook is bent immediately from the end of the spoon or released 2-4 millimeters. The neck with the sting is retracted at an angle of 15-20 degrees. The back of the hook also has a characteristic shape (Fig. 3). For a large spoon, you can also use a factory hook with a barb, after first releasing it on the fire and giving it the desired shape.

All sizes of the spoon decrease in proportion to its length.

Hooks for such spinners are made from sewing needles. They can withstand large fish, do not bend or break, are unnoticeable, very sharp, and make it easy to remove fish, which is important in the cold.

To make such hooks, you need to have steel sewing needles of different numbers:

- for small perch, roach, grayling - No. 3-4, sometimes even No. 2;

- for large fish (whitefish, large perch, ide, etc.) - No. 5-6.

The needles must be driven, their length does not matter. Hooks are made using small pliers, one of the planes of which is rounded by 2-3 mm. A special bend made from the eye of a thick needle driven into a wooden handle is also suitable for this. Anneal the needles in the flame of a match or candle. Start annealing near the thick end of the needle and observe the color of the tarnish. Stop annealing when the blue stripe that appears when heated approaches the thin tip of the needle.

After this, the tip of the needle is clamped with tweezers to the required length of the sting and bent around their flat antennae. Using the rounded side of the tweezers, the fore-end is slightly bent and a hook blank is obtained. Then, along the required length of the hook, a hook ring is bent around the rounded tendril of the tweezers, which should be perpendicular to its plane. The hem is first made in the direction opposite to the future ring, and then it is completely bent around it.

It is very important to configure the hook exactly as shown in the picture, otherwise it will not work well. These hooks must be tied with the point up, so that the fishing line is located at a right angle to the hook.

Making a homemade jig

If you have a soldering iron, you can use the method of fusing a jig. Having picked up the hook, you need to fix it motionless and degrease it, and then gradually make a surfacing of tin. A regular needle file will help you adjust the shape of your homemade product.

Another way to make a simple jig is to wind thin wire around a single hook. To do this, you just need to increase the bend of the hook, and then carefully wind the copper wire from the tip to the forend; At the end, press tightly with the same pliers.

Casting jigs requires preliminary production of a mold, which most often consists of two plaster halves with imprints of the donor bait. A hook and a piece of wire (under the fishing line) are placed in the finished form. The two plaster parts are connected, and then lead is poured through the hole made in advance. When the workpiece has completely hardened, it is sanded and, if desired, painted in the desired color.

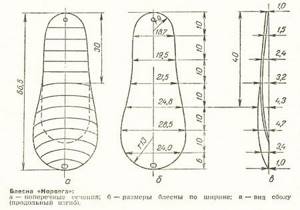

Drawing of a homemade spinner “Norway”

What other vibrators can you make yourself?

Thin metal spinner

To make such a spinner, sheets of non-ferrous metals and alloys less than 0.5 mm . Such blanks are easier to cut (you can use metal scissors) and process. The process of making a spoon is not fundamentally different from working with thicker spoons.

The resulting bait is light in weight and catches pike well in shallow water with a very slow retrieve. But much more often, the lure needs to be cast a decent distance and fished with it at depths of more than one meter. Then you need to load the spoon.

Loading

In order to load the spoon, it is required:

- tin;

- fill with lead.

Expert opinion

Knipovich Nikolai Mikhailovich

Zoologist, hydrobiologist. I am interested in fishing at a professional level.

Important! When working with lead, you should be extremely careful, as its fumes are hazardous to health. It is advisable to melt lead in the open air, under a hood or in a respirator.

After pouring lead, the workpiece is processed with a file, polished, holes are drilled and equipped with all the necessary elements. By the way, it is not at all necessary to paint the lure. Sometimes the natural shine of copper, brass and cupronickel attracts a predator much more strongly than a fancifully painted bait.

Bimetallic spinners

Spoons, the two sides of which are made of different metals, are widely used in winter fishing . At the interface of two metals, a contact potential difference arises. It is believed that this attracts fish, although the effect of this phenomenon on the bite has not been fully studied.

In summer, bimetallic spoons are also used. The two sides of the spinner are fastened together with a layer of lead, which is also its weight.

Spoons from a tube

The metal tube is cut on both sides at certain angles and a catchable vibrator is obtained. The spinner has a sweeping action and attracts pike well. If you solder the front end of a spinner tube, it begins to emit acoustic vibrations. By filling the tube with lead, we get a long-range spinner.

Castmaster

Castmaster is a spinner for long-distance casting , made from a piece of metal rod. Its catchability is ensured not only by the precisely observed cutting angles invented by its inventor, but also by the fact that it is made of non-ferrous metal . Chinese iron copies are not nearly as catchy.

To make it you will need a metal rod of round cross-section. The rod is cut at both ends, carefully maintaining the angles of the cuts, holes are drilled and the spoon is equipped with fittings and a tee.

Expert opinion

Knipovich Nikolai Mikhailovich

Zoologist, hydrobiologist. I am interested in fishing at a professional level.

Healthy! Many people believe that Castmaster is intended exclusively for asp fishing. However, with the Kastmaster you can successfully catch pike, perch, pike perch, trout and grayling, using both uniform and stepped retrieves.

Lead spoon

It is possible to make an all- lead spinner .

Before casting it, it is necessary to prepare a mold, which is usually made of plaster. Observing the above precautions, the molten lead is poured into the mold, the workpiece is allowed to cool, the workpiece is removed, and the workpiece is brought to perfection using a file and sandpaper. Then the front and rear holes are drilled, the spoon is painted and equipped with fittings and a tee.

Non-hooking spinners

You can’t do without non-hooking spinners when fishing for pike in “toad fisheries”. The spoon itself is made in the same way as a spoon with open hooks. Then it should be equipped with a single or double hook and elements should be attached to it to ensure non-catching .

Hooks are attached in two ways:

- A cut is made along the back of the spoon, into which a hook with a bitten eye is inserted, and the shank of this hook is soldered into the cut.

- A hook with an eye (not an offset hook) is applied to the back of the spoon and a place is marked for the hole that will serve to attach the hook. A hole is drilled in this place, a rivet is inserted into it and into the eye, and the hook is riveted to the spoon. If necessary, the forend is bent so that it fits tightly to the surface of the spoon. This way you can rivet both single and double hooks.

Equipment for non-clinging of the spinner can also be made in two ways:

- Two “whiskers” made of elastic steel wire are soldered to the front of the spoon.

- To protect the hook, a loop of thin elastic wire (you can take a string) is used, the rear end of which is soldered to the front of the spoon. The second option has greater cross-country ability through grass.

- The laziest can glue a bunch of stiff bristles from a floor sweeping brush with Poxypol.

Spoons made from scrap materials are popular because their manufacture does not require any special skill or serious tools.

You can make two whole spoons from a cupronickel silver spoon: from the handle an analogue of the “Devon”, from the remainder - a spinner “Spoon”.

By flattening a coin, you can get a working micro-oscillator. Having given the piece of metal the necessary bends, it needs to be equipped with rings and a hook, preferably a single one.

By connecting several coins in series, a loud-sounding composite vibrator is obtained.

Abu Garsia Atom spinner is made from plumbing corrugated copper pipe .

A blank in the shape of an elongated oval is cut out of the pipe wall, leveled and, after making holes, equipped with everything necessary.

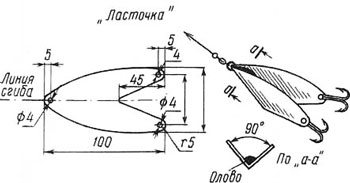

Homemade spinners “Swallow” and “Poprygunya” by L. Borisovets

For many years he used homemade spinners “Lastochka” and “Poprygunya”, which he highly recommended for catching asp. Their weight is 37-45 g. When retrieved, they fussily jump out of the water, which always attracts the asp.

The “Swallow” and “Poprygunya” spinners are made of silver-plated or tinned brass, 1.5 mm thick. First, according to the dimensions shown in the figure, you need to cut out the blanks and drill the required holes in them with a diameter of 4 mm. The Swallow blank should be bent along the dotted line at an angle of 90°. Rivet two double hooks No. 12 to the “wings” of the spoon tightly with copper rivets with a diameter of 4 mm. A strip of tin should be soldered into the groove of the “Swallow” spinner to bring the weight of the spinner to 35-40 g.

The “Jumper” blank must be bent as shown in the figure, and the “wings” of the spoon in the bow must be bent upward at an angle of 40°. In the tail part, pour a lead ball with a diameter of 12 mm. This is easy to do in a plaster mold. Then you need to install the winding rings, carabiner and tee No. 14. Spoons should be cleaned with coarse sandpaper, but not polished. Polished lures repel fish with their glare.

Lures are attached to the line without a leash. Their weight allows you to cast up to 70-80 m.

“Swallow” and “Poprygunya” were tested in the Volga, Syr Darya, Neman and Western Dvina basins. The asp always pecked at these spoons very actively.

Spinner

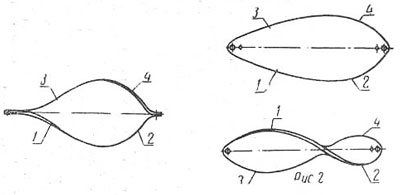

M. Schwartz proposed the following design of a rotating spoon.

The spoon is made of metal. The workpiece has the form of an ellipse-shaped plate (Fig. 1).

The plate is bent in the longitudinal direction along a helical line (Fig. 2). The edges of the plate have two sections: 1, 2 and 3, 4, which are bent in pairs in opposite directions. So, section 1 is bent in one direction, section 2 in the opposite direction. Sections 3 and 4 are also bent. In relation to the transverse axis of the spinner, the bent sections of the edges are asymmetrical. For example, sections 1 and 3 are longer than sections 2 and 4. The amount of edge bending may vary. There is a hole at both ends of the spoon, into each of which a winding ring is placed. When the spoon is immersed in water and while being retrieved, it rotates and this attracts predatory fish. The more elongated the ellipse, the less rotation it has and vice versa.