If you need to repair a rubber boat, then you need to look for good glue.

There are many types of glues on the market, but to repair a rubber boat you need a really high-quality glue. It will be very disappointing and not helpful if the adhesive joint comes unglued. It is especially dangerous if this happens on the water while moving. Therefore, many people believe that using the glue that is commercially available, it is almost impossible to properly repair a boat.

What glue should I use to seal a rubber boat?

Glue for a rubber boat should be slightly different from regular rubber glue, for the better. Therefore, when choosing glue for a boat, you should focus on some recommendations:

- It is necessary to immediately discard cheap products, since such adhesives do not differ in quality. In addition, sometimes they are made of unknown components. In addition, they can render the areas being repaired unusable.

- You should not resort to buying superglue (cyanoacrylate) if you need to properly and permanently seal the boat. Despite the fact that superglue makes a strong connection, it will not last long. As a rule, such a connection cannot withstand temperature changes.

- It should be an adhesive that has high heat resistance and can withstand temperature differences.

- First of all, you need to give preference to special, but not universal adhesives that can glue everything, but not so well.

- When gluing a boat, you need to remember that the presence of a small amount of moisture can lead to a loss of joint strength. Therefore, before the repair process, the boat must be thoroughly dried.

- The main focus should be on its non-stickiness. Many people believe that the more glue sticks, the better quality it is. This is actually a misconception.

The most suitable glue for repairing a boat is the glue that came with the boat. If glue was not included in the kit, then you can purchase black rubber glue “ Radical ”. It is affordable, water-repellent and provides a quality connection. Not bad results can be obtained when using polychloroprene adhesives.

The composition of the glue is always indicated on the packaging, so it is necessary to have such information.

The higher the temperature conditions of the surfaces being glued, the better the quality of such a product.

In any case, before starting work it is better to carry out experimental gluing of two pieces of rubber. After complete drying, maximum effort is applied to the parts. Based on the results of the experiment, a conclusion is made about the quality of the glue.

PVC glue comparison

Choosing the best glue

Not only the comfort of passengers, but also, most importantly, their safety on the water depends on competently carried out repair work on an inflatable craft. If done incorrectly, the patch may become depressurized and the boat will begin to deflate or fill with water, which will lead to negative consequences.

A high-quality adhesive composition must meet the following requirements:

- The drying time of the repaired seam is especially important in camping conditions.

The adhesive should not be based on cyanoacrylate. The use of “super glue” is not allowed. Despite all its advantages (it instantly and firmly glues surfaces), the product does not have the necessary elasticity, which leads to the destruction of the seam.

- The adhesive must be of good quality. To check this parameter, you can use the following technique: apply a thin layer of glue to any surface and leave for 5 - 7 minutes, then check it for stickiness. A low quality product will stick to your fingers. The use of Moment glue is also not advisable.

- The versatility of the adhesive composition is not always justified ; it is better to use special-purpose products (for PVC boats).

- One of the important parameters is the thermal stability of the composition. For swimming equipment made of polyvinyl chloride, it is recommended to choose products that can withstand sudden temperature changes (-40 to +70 degrees).

- Using compositions based on polyurethane or chlorpropylene is not effective , given the sensitivity of the components to moisture. The quality of the seam will be low and unreliable.

- Harden quickly. The drying time of the repaired seam is especially important in camping conditions.

- High-quality glue cannot be cheap ; saving here is not advisable.

Rubber boat repair process

Repairing a rubber boat is not as easy as it seems, especially for beginners. For owners who have already encountered a similar situation, repairing the boat is not a big problem.

The most important thing is to at least have an idea of repair technology in order to know where to start. And they always start by preparing all the necessary materials and tools. For example:

- Prepare patches from pieces of rubber, the size of which should be larger than the size of the crack or tear.

- Special rubber glue.

The main task is to determine the location of the leak if there are no visible breaks. To do this, the boat needs to be pumped up and launched into the water. If this is not possible, then the boat can simply be watered. Air bubbles will definitely appear at the puncture sites. Now this place needs to be marked, for example, with chalk. After this, the air is bled from the boat, and the boat is installed in an open space. This is necessary so that it dries well. In this case, there is no need to rush too much, since the presence of a minimal amount of moisture can ruin everything.

Only after the boat has dried thoroughly can you begin to repair it. To ensure a high-quality and reliable boat repair, the glue is applied strictly according to technology. Even minor deviations from gluing technology will lead to poor-quality connection of the bonded surfaces. Under the influence of temperature differences - water temperature and the temperature of the surface of a boat heated in the sun, a hastily made connection can easily come off.

Repair of a rubber inflatable boat.mp4

What will be needed for repairs

Before repairing a PVC boat with your own hands, you need to prepare the tools and materials that will be needed in the process:

- The patch should usually be included in the repair kit when purchasing a boat. If this is not available, then purchase it at the store, since other material will not last long.

- Boat glue. It also comes in the set. However, manufacturers can save on material and use a low-quality composition. Therefore, checking the quality of the adhesive mixture and its shelf life is mandatory.

- A simple pencil for recording calculations.

- Brush for applying the adhesive mixture.

- Scissors for cutting a specific size of fabric.

- Degreaser: acetone, nail polish remover, alcohol.

- Hairdryer for heating matter. Preferably a construction one, but a home one is also suitable, using it at a higher setting.

- Rubberized roller for smoothing and expelling air bubbles.

- You may also need keys and screwdrivers.

If repairs will be carried out urgently, in an open area, then be sure to have a repair kit with you. Then you won't need a hairdryer.

A few simple recommendations

- To obtain a strong and reliable adhesive connection, you must follow some rules. Without fail, each bonded joint must go through a degreasing process with solvent, acetone or gasoline. In addition, the gluing areas are rubbed with sandpaper. This technique improves the bonding process between the base and the patch.

- If the cracks on the boat are too large, then before gluing it is advisable to tighten them with nylon threads. This technique will strengthen the gluing area.

- Most adhesives require constant drying of each layer during the gluing process. An ordinary hair dryer or a hair dryer will help you cope with this task.

- Working with glue requires a well-ventilated area. The best option is to work outside, but only if the air humidity does not exceed 60%.

When gluing surfaces, other important factors should be taken into account. Hands should be clean, and most importantly, not greasy. It is also not recommended to glue in the sun, when the gluing area overheats under the influence of sunlight. Fast setting of glue will not lead to reliable results. Plus, you should never forget about excess moisture.

How to glue the bottom of a boat?

Gluing the bottom (PVC) onto a rubber boat

As a rule, the bottom of the boat is subjected to the greatest mechanical loads, which can cause various types of damage. To glue the bottom back to a rubber boat, you need to follow certain rules.

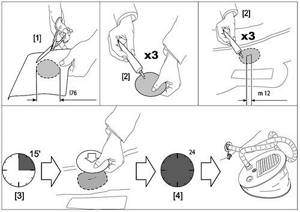

Before the gluing process, it is necessary to completely tear the bottom off the boat, then heat it with a hairdryer and clean it well with sandpaper. Then you need to glue the sealing tape. Only after this should you start gluing the bottom.

The operation of gluing the bottom is carried out with the boat at full, maximum inflation. After this, the air is completely bled off and the boat should remain in this state for 48 hours until the glue dries completely. During the work process, it is necessary to strictly follow the technology for working with glue, otherwise a high-quality connection will not work.

Gluing

If the boat is leaking along the seam near the valve and the damage is small, back seam gluing will help:

- Open the inflation valve and use a special key to disconnect it from the leg.

- We insert two fingers into the valve hole and gradually pinch to reach the outer joint of the seam.

- We remove the old glue, degrease and coat with glue the strip that releases air.

- If necessary, dry with a hairdryer.

- We wait 12-24 hours (depending on the instructions for use).

- Let's check the result.

How to seal a seam from the outside without a patch in those places where there is tape that has lost its functionality:

- We fill the cylinders with air into three parts (75%) so that the seams straighten.

- We treat the surface as described above.

- We apply glue to the seams in the amount recommended by the manufacturer (usually a few millimeters thick).

- Make sure that the glue is distributed evenly and all joints are filled with it. It is better to apply the composition with a brush.

- Press the surface parts tightly against each other with your hand.

- Leave the boat inflated until the seam is completely dry.

A way to seal a hole in a seam or other place with a patch:

- After treating the surface, apply glue to it (you don’t have to apply it to the patch). It is better to apply glue to the damaged area in 2 layers: the first thin one, then wait 10-15 minutes, then the second layer and immediately proceed to further actions.

- We attach a patch.

- Smooth it out to remove all the air from under it.

It is better to avoid fishing in this boat for the next 3 days.

How to glue a seam on a rubber boat: video instructions

Popular brands of glue for rubber boats

Glue, brand 4508, is the most popular glue in our time. The basis of this glue is natural rubber. Distinctive features of this glue:

- acceptable stickiness;

- acceptable elasticity of connections.

You can also find polyurethane glue, which has strong adhesive properties. Gummi glue, made from rubber, can withstand moisture. It can also be recommended for use.

Glue "Radical"

Many owners of inflatable rubber boats use Radical glue. It is resistant to low temperatures, strong mechanical stress and salt water, making it ideal for repairing rubber boats. This glue is made on the basis of rubber, with the addition of various solvents and fillers, which provide it with excellent performance characteristics.

FAQ

Repairing rubber boats can be accompanied by certain difficulties, depending on the nature of the damage, as well as the personal capabilities of the owner. Some take the process very seriously, while others try to “cover up” the damaged area with whatever is necessary. In this regard, some owners of rubber boats turn to professionals for advice or look for answers to their questions on the Internet.

Some clients are interested in the question regarding the use of Moment glue for repairing rubber boats. The answer to this question can be very simple: if the instructions indicate that it can be used to glue rubber products, then Moment glue can be used to repair rubber boats. But at the same time, you need to take into account some features of this glue: you need to work with it very quickly. This is a contact adhesive, like superglue, although there are other developments. The advantages of using Moment glue are:

- gluing speed;

- ease of use.

Despite this, you need to be prepared for the fact that the bonded surfaces will not last long. This glue is sensitive to elevated temperatures and it is unknown how it will behave after warming up in the sun.

Moment glue is a good option for a quick solution to the problem. For example, you can take it with you fishing or on a trip, and if something happens, you can quickly and reliably seal the hole. The advantage is that you do not need to wait for the connection to gain its strength, since it can be used immediately. The glued surface can serve throughout the entire trip, but upon arrival home, it is advisable to re-glue the damaged area with another glue, adhering to all the technology.

This is why experienced owners refuse to use Moment glue: why glue it twice if you can do it once and for all.

PVC boat and one-component adhesive in the sun

How to get rid of old rubber glue?

It is very difficult to wash off old rubber glue from bonding areas. The fact is that the glue connects to the rubber surface at the molecular level. Therefore, using force when removing old glue is not recommended at all, as this can lead to even greater damage to the boat. It is also not recommended to remove it using various solvents or other aggressive means. Therefore, it is extremely difficult to recommend anything. Perhaps you can try and remove some of the old glue using an abrasive method, armed with sandpaper, but very carefully so as not to damage the boat’s cylinder.

Repairing a rubber boat using shoe glue

Some owners use shoe (nairite) glue to repair their boats, as it has excellent water-repellent properties. In addition, the adhesive connection has a certain flexibility and strength. In addition to rubber, it also glues other materials, such as leather, wood, fabric, and so on. Naturally, gluing must be done strictly according to technology.

Before each summer fishing season approaches, you should check your boat in advance for any defects. Moreover, the boat was in storage for the whole winter. The sooner this is done, the faster the problem will be resolved. The most important thing is to choose the right glue so that the repair is not temporary, but lasts a long time and you don’t have to worry about the boat coming apart at the most inopportune moment. This is very important because you have to fish at considerable depths. Personal safety should always come first.

Igor 05/21/2017

Description of PVC panels

The abbreviation PVC stands for polyvinyl chloride. In fact, it is ordinary plastic, which was given the desired shape during production. PVC panels have been used as a finishing material for many years. This became possible thanks to the undoubted advantages that the panels have. Among them are:

- Durability, service life up to 10 years.

- Easy to care for.

- Environmentally friendly.

- Moisture resistance.

- Fire safety.

- Resistance to low and high temperatures.

- Good sound insulation.

- Can be attached to different surfaces and the like.

Many customers also like the fact that the stores offer a huge number of colors, with a variety of designs printed on the panels. If you want to make an inexpensive but beautiful renovation, then this material will be a good choice. The main thing is to choose a good manufacturer and pay attention to possible defects in the product. The panels are easy to buy and, importantly, easy to install.

There are two main ways in which you can attach plastic panels to the wall:

- Attaching panels to the frame. This can be done mechanically, that is, using screws, nails or staples. The sheathing itself can be metal, wood or plastic. The panels can also be glued to the frame, which in this case will act as a wall leveler. This method of fastening - to the sheathing - has its pros and cons. Those who don't want to spend too much time installing the frame and lose precious square centimeters in the bathroom can choose a different route.

- Gluing to the wall. This method has virtually no effect on the area of the room being repaired. But it has its limitations. The walls must be smooth, dry, and the adhesive composition must be well selected, then the repair work will give the right result.

You must understand that not every glue is suitable for attaching this finishing material. Some compounds may damage the plastic or do not withstand moisture well. Therefore, it is better to know in advance than to glue PVC panels to the wall.