Description of the procedure

There are a lot of factors that cause damage to the bottom of the craft, as well as its cylinders and other elements, for example:

- wear of the material, its abrasion;

- rupture when the bottom and lower part of the cylinders come into contact with the rocky soil of the reservoir, pebbles, and so on;

- puncture or cut by a sharp object (dropped a knife, hooked a fishing rod, etc.);

- a spark got on board.

You can simply sit on the inflatable board when the boat is on the shallows, and get a breakdown or rupture of the lower part of the skin. Likewise, when pulled ashore, careless dragging over pebbles can cause damage to the polyvinyl chloride layer. As you can see, there are a lot of factors, and they are very heterogeneous.

A way to resolve the problem can be such an event as armoring the lower part of the boat from polyvinyl chloride, strengthening and thickening the bottom and inflatable sides . At the moment, many methods have been invented, using which you can free yourself from such problems for a long time.

The main thing when carrying out all strengthening measures is to take into account the following nuances:

- the weight of the craft, which can grow to 7-12 kilograms, it all depends on the dimensions of the craft and patch;

- It is worth remembering that as a result of gluing polyvinyl chloride, the dimensions will increase by 2-3 centimeters;

- what material will be used for the armor (since the boat is made of polyvinyl chloride, then it is necessary to make an additional bottom from polyvinyl chloride strips or specialized rubber-coated strips, but fishermen often use other, waterproof materials);

- the thickness of the glued polyvinyl chloride should be within 3-5 millimeters;

- which areas of the bottom are armored (this depends on what the reinforcement is for).

However, basically it is:

- inflatable keel;

- the lower part of the cylinders;

- bow of the craft;

- transom fixation location;

- areas of mating of longitudinal stiffeners (stringers) in the cockpit.

It should be taken into account that strengthening the center band and torpedoes will bring little protection and slight stability. But with extensive armoring of the bottom or even the entire craft, you can be sure of the boat.

The main thing is to use the appropriate glue. In addition to all the underbody protection, auxiliary reinforcement can be provided.

Main causes of damage and benefits of enhancements

There are many reasons why damage occurs to the bottom of the boat, as well as its sides and other parts, for example:

- wear and tear of the material;

- rupture when the bottom and lower edge of the sides come into contact with a rocky bottom, pebbles, etc.;

- puncture or cut with a sharp object (dropped a knife, caught it with a fishing hook, etc.);

- spark getting on board.

You can simply sit on the inflatable side of a boat standing in shallow water and get a rupture or puncture in the bottom. Also, when pulled ashore, careless dragging over pebbles can damage the PVC layer. As you can see, there are many reasons and they are quite diverse. A solution to the problem can be a procedure such as armoring the bottom of the boat with PVC, strengthening and thickening the bottom and sides. Modern science has invented many methods, using which you can save yourself from such problems for a long time.

The procedure for booking the bottom of a boat provides a number of advantages; as a result, the money spent is not wasted, but becomes a profitable investment, namely:

- increasing the strength of the bottom and reducing the likelihood of holes and ruptures;

- extending the service life of the product, because resistance to abrasion, atmospheric influences, etc. increases;

- the boat acquires better gliding properties, which affects performance;

- the price of the boat increases, it can be sold for more.

As for the disadvantages, one of them can be noted is a slight increase in weight, its magnitude depends on the dimensions of the boat and the thickness of the protective layer applied to its bottom. This indicator is also affected by the material used for booking. After the procedure, the size will increase slightly, but also slightly, ranging from 2 to 3 cm.

According to the current opinion among fishermen and tourists, such minor inconveniences are more than compensated for by an increase in service life and improved performance, and the use of modern polymer materials allows one to avoid a significant increase in the weight and dimensions of an inflatable small boat.

What is needed to reinforce the bottom with PVC

For vulcanization, you need to choose suitable and reliable tools, without missing anything.

At the same time, their quality must be appropriate:

- material for the bottom, preferably PVC 3 - 5 mm;

- construction or regular tape;

- a hair dryer, preferably a construction hair dryer, it has more power;

- glue specially designed for PVC materials;

- patterns, possibly from cardboard;

- roller or bottle;

- alcohol, solvent or any other grease remover.

It is better to purchase all the necessary components in advance or make do with improvised means. It all depends on how thick the reinforcement the fisherman wants to get.

Gain Features

When performing all strengthening work, the following must be taken into account:

- Boat weight, which can add up to 7–12 kg , all depends on the size of the inflatable transport and patch;

- We must not forget that after gluing PVC, the dimensions become 2–3 cm larger;

- What material will the reinforcement be made of? Since the liquid is made of PVC, it is advisable to make an additional bottom from PVC tapes or special rubberized strips. But fishermen often use other, non-wetting fabrics;

- The thickness of the attached PVC should be within 3–5 mm;

- Which parts of the bottom are reinforced? It depends on the purpose of the strengthening. But most often it is: an inflatable keel;

- bottom surface of cylinders;

- nose;

- transom mounting location;

- stringer connection points in the cockpit.

In addition to all bottom protection, additional reinforcement can be provided.

By using:

- Polymer liquid. It opens and is spread on a previously prepared part of the transport. Some types of it are used to fully book an object;

- Fishermen also make reinforcements from strips of plastic, aluminum or duralumin. By placing them on rivets in the center, in front or on the rear of the vehicle. This method is not very good because it spoils the PVC by washing it. And interferes with the normal assembly of the object.

You can strengthen any place on the boat in different ways, depending on your knowledge and imagination.

Pros and cons of amplification

The process of booking the bottom of a boat brings a number of positive aspects; in total, the money spent is not wasted, but turns into a profitable investment. Through this procedure the following occurs:

- increasing the strength of the bottom and reducing the possibility of tears and punctures;

- increasing the service life of the product, as resistance to wear, atmospheric influences, and so on increases;

- the boat gets better planing properties, which affects the performance;

- the cost of the boat increases, it can be sold at a higher price.

If we talk about negative aspects, then among them a certain increase in mass can be affected; its value depends on the dimensional parameters of the watercraft and the thickness of the protective layer used on the bottom. Additionally, this indicator is influenced by the material used for booking. After modification, the dimensions will increase somewhat, but also not too noticeably, within the range of 2 to 3 centimeters.

According to the prevailing opinion among fishermen and travelers, such minor inconveniences will be fully compensated by increasing the duration of operation and improving the running properties, and the use of the latest polymer materials makes it possible to eliminate the impressive increase in the weight and size of the boat.

How to protect the bottom of a PVC boat

One of the exotic methods of protection is gluing flakes made of PVC to the bottom . It turns out to be a kind of dragon skin. But this method increases the weight of the boat. Yes, and you will have to glue these scales for more than one day. Nobody will do this serially, and if they do, then in terms of costs this method is unreasonably expensive.

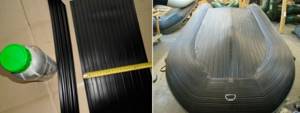

Additional (second) layer of PVC on the bottom of the boat . This is a more efficient method with less labor. This method of protecting a boat is widely used by manufacturers of small inflatable boats. And it is within the power of a person with hands growing from the right places to bring it to life independently. And there is also an economical option for such protection - PVC tapes or special rubberized tapes, glued to places subject to the greatest wear : the inflatable keel, the lower surface of the cylinders, the bow, the transom attachment point, the connection points of the stringers in the cockpit.

But you can book at least the entire bottom or even the entire hull of the boat and the top too. This method is also called “bottom reservation”. It is only highly recommended to use the correct glue for gluing PVC fabric. Otherwise, after some time, everything will go smoothly for you if you glue it with some kind of garbage. But all those extra layers again add to the overall weight of your boat.

Booking materials

There are several methods of strengthening, each of them has its own advantages and disadvantages. Armoring can be applied to the entire bottom of the PVC inflatable boat, or only the parts at greatest risk of abrasion or damage can be reinforced. Main methods include:

- gluing PVC scales to the bottom (dragon skin effect);

- additional layer of PVC on the bottom;

- reinforcement with polyurethane film;

- PVC tape;

- rubberized tape;

- liquid polymers.

Gluing “dragon scales” is a long and labor-intensive process; not everyone wants to spend time on this procedure. An additional layer of PVC material is a less complex and time-consuming process, while PVC tape applied for reinforcement and armoring to areas subject to the most stress, such as boat bottoms, will be a simpler and more economical option, significantly reducing costs. You can also use rubberized tape for these purposes using special glue. Separately, it is worth considering the use of liquid polymer materials.

Use of liquid polymers

Modern science has introduced so-called elastic polymers - chemical compounds in liquid form that polymerize when applied to the surface of a boat. Polymerization gives exceptional strength; this layer will not come off under any influence.

Polymers combine properties hitherto incompatible in one substance - high plasticity and resistance to mechanical stress. Such qualities are obtained by adding special plasticizers and additives during the production process that affect the physical and chemical properties of the final product.

As a result of coating the surface of the boat with liquid polymer, it acquires the following properties:

- resistance to mechanical stress (abrasion, tearing, cuts, etc.);

- resistance to aggressive chemicals;

- increased resistance to ultraviolet radiation;

- increased weather resistance, especially to temperature changes.

It is worth noting that the applied polymer layer differs from other types of coatings in the thinness of the layer, which does not exceed 0.8 mm, and its density is close to the density of the boat material. All this allows you to minimize the amount of weight added after processing. If desired or necessary, it is possible to apply several layers of polymer. Polymer compositions are sold in special stores, and their application does not require special knowledge and skills.

Do-it-yourself boat reservation

To book the bottom of a PVC boat with your own hands, you do not need to master any special skills. You need care, accuracy and the necessary tools and materials for the work, these include:

- material that will be used to apply to the bottom;

- scotch;

- patterns (can be made from paper or cardboard);

- glue (when using PVC materials);

- construction hair dryer;

- surface degreasing agent (solvent, alcohol, etc.);

- roller

The preparatory process includes inflating the boat, removing dirt and degreasing the surface. It must be turned upside down. In case of incomplete application of reinforcement, patterns are used, with their help parts of the corresponding shape are cut out of the material. According to their outlines, tape is glued to the boat to protect the untreated surface.

In the case of using PVC canvas or tape, the surface is first warmed up with a hairdryer, then glue is applied in 2 steps. The surface of the material to be glued is also lubricated. Then the material is applied and rolled with a roller, and if necessary, heated again with a hairdryer. Drying usually takes 2 or 3 days. If liquid polymer is used, it is applied in accordance with the instructions for use, this applies to both the preparation of the boat and the polymerization conditions.

Film for armoring PVC boats

The film allows you to repair boats and other inflatable structures from almost any manufacturer, including imported ones.

The cost of the material itself is very modest - often a whole boat needs film for no more than 10,000 rubles, but it lasts for many years.

Yes, you need to take into account the cost of glue and pasting services (if they are glued to order), but in any case the cost is not that high.

Bottom reinforcement

The PVC fabric that serves as the bottom of the boat is quite durable, but it is inconvenient to move on. Since the bottom is not hard, every angler experiences a number of inconveniences. Therefore, strengthening the bottom is the primary task. In the future, the reinforcement will have to be repaired, but not the bottom of the boat. This will cost less, and it will be easier to replace the reinforcement with a new one or repair it. It is possible to carry out both full and partial reinforcement of the bottom of the boat.

The bottom is reinforced by gluing a special PVC tape, which is called a “fender bar”. The fender can have a thickness of 1.2-3 mm with a width of 60-235 mm. It is attached using 2-component glue. This will make the bottom harder and more protected from various underwater surprises.

Keel reinforcement

The operation boils down to gluing PVC tape (fender) over the factory tape. Similar reinforcement extends to the keelsons.

Strengthening cylinders

Reinforcement is carried out based on need. Cylinders are also subject to constant wear and tear.

Transom protection 27 mm (top protection)

U-shaped profile or transom protection on top. Used for PVC inflatable boats as a lining to protect the upper end of the transom with a thickness of 27 mm, which is most susceptible to damage when... Width 27 mm Side height 10 mm Thickness 3 mm Material PVC Color black Country of origin Russia

L-shaped profile (transom protection from below)

L-shaped profile or transom protection from below. It is glued to the outside of the transom with special glue. The wide part is towards the bottom of the transom, the narrow part is towards the side of the transom. Protects the transom from damage upon contact with... Width of the wide part 35 mm Width of the narrow part 15 mm Thickness 2 mm Material PVC Color black Country of origin Russia

Installation of stringers

If the boat has a hard floor, you will have to install duralumin profiles. Since the boat is deformed while moving, the hard floor pads touch the inflatable parts of the boat and a friction process occurs. This can lead to abrasion of the fabric, which is undesirable and can compromise the strength of the boat. In the bow, where the profile of the boat has a curved shape, stringers are not installed.

Polymer elastomers for boat protection

New technologies are sweeping the planet. Nowadays there are a lot of modern polymer materials in a liquid state . This composition is applied to areas subject to increased wear. “Liquid protection” polymerizes and becomes integral with the PVC material. Their peculiarity is that they have good strength, elasticity and abrasion resistance, sometimes even surpassing some metals. In addition, polymers may have properties that contribute to noise absorption and vibration reduction. Operating temperature range from -70 to +120 C.

In specialized stores you can now find polymers from the elastomer class. They combine seemingly incompatible properties - elasticity and hardness. They also have increased resistance to tearing and abrasion and protect well from chemical attack. And in terms of abrasive resistance it is 3 times better than rubber and even steel . Polymer elastomers obtain such excellent qualities due to the free energy that is stored in their body. They contain a “memory” of the shape they received during casting and under any load they provide a joint resistance and themselves heal defects and deformations, maintaining hardness.

The physicochemical properties of elastomers can easily be changed by changing the recipe for their preparation.

What kind of boat protection do polymer elastomers provide:

- from cuts and punctures

- from tears

- from abrasion, reducing friction

- from aggressive chemical influences

- from overheating and ultraviolet radiation

The thickness of the layer applied to the body of the inflatable boat cylinders is from 0.5 to 0.8 mm and such a layer corresponds to a density of PVC material of 900 g/sq.m. If this is not enough, you can apply several additional layers and bring the thickness up to 50 mm.

The polymer is selected depending on the required properties and characteristics.

- Some elastomers do not react at all to air humidity, but at the same time, after hardening, they have poor elasticity and are suitable for surfaces that do not require folding or are not very susceptible to bending.

- There are some that have a loose, porous structure. It has very good vibration and noise absorption.

- And of course, you can choose a universal polymer elastomer that is suitable for protecting all elastic surfaces of a PVC inflatable boat. Apply it to the bottom contours and cylinders and you will not only receive improved protection from various types of damage, but also increase gliding through the water, reducing the time to glide, increasing the maximum speed without replacing the engine and reducing fuel consumption.

Polymer elastomers are now the leading technology for protecting the bottom and hull of inflatable boats from all types of damage and impact.

Making a hard bottom in a PVC boat

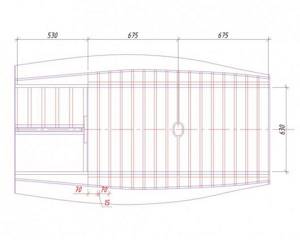

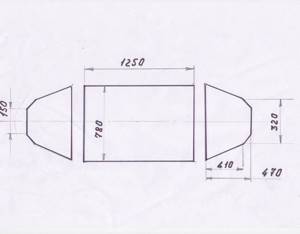

The first thing to do is measurements and drawings. Detailed accuracy is important here. Some may be able to make the bottom without drawings, but most “homemade” ones need them for an ideal result.

Making a drawing

First we take measurements. Remember that the new bottom must completely match the place where it will be inserted. If it turns out to be less, it will not only disturb you, but also wipe the fabric of the cylinder and the bottom of the boat. It is difficult to insert a pad larger than the required size into the boat, and strong pressure will be exerted on its material, which will lead to gradual destruction.

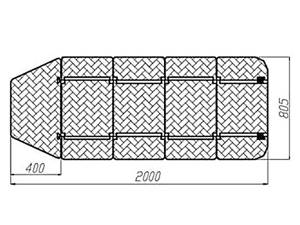

To make a drawing, measure the bottom of the boat. The width of the rectangular part of the bottom should be increased by a couple of centimeters.

For drawings, you can use computer programs or special sheets for drawing a sketch. Look at some of the drawings and make your own or simply copy the appropriate one, replacing the dimensions with your own:

Drawing No. 1

Drawing No. 2

Drawing No. 3

Making the bottom

One of the options for making the bottom in the video:

DIY slan (hard bottom) for a PVC boat

Now we make a pattern from linoleum according to our drawings. By the way, this linoleum will be needed as a layer between the made bottom and the standard PVC floor (otherwise it will be damaged by the fittings of our “creation”).

The pattern should be smooth, with equal sides. To do this, fold it in half and trim the edges if necessary. Using this piece of linoleum, we mark the length of our accordion on the plywood and cut out strips of the width we need from it. Of course, the bow will be different from the rest.

Now you need to process all the parts:

- Sand the surfaces with sandpaper.

- Using a file, hacksaw, or jigsaw, we round the sides. There should be no sharp protrusions or burrs, otherwise they will pierce the container or bottom.

- We impregnate the plywood on all sides. Yacht varnish or similar enamel protects the material from water that might get into the boat. Even if you have moisture-proof plywood, applying varnish is a mandatory step. When swollen by water, the accordion will not fold and will not even fit into the boat.

If you decide to make the bottom out of plastic, the ends need to be sanded, and the edging can be made with a tarpaulin.

Before applying varnish, it is not necessary to treat the plywood with an antiseptic, because the varnish will make the material waterproof. If you still decide to use an antiseptic, choose a universal composition against all fungi.

Perform varnish treatment in a well-ventilated area, ideally outdoors. We recommend applying varnish in 2-3 layers.

The plywood will dry for several days. During this time, you can explore the assortment of our store. We are sure that you will find something extremely useful for yourself!

It's time to put our pieces together. To make the structure easy to fold, we take a bolt with a countersunk head. The payol is attached to it. An ordinary grinder will help remove excess parts from the bolts. To ensure structural rigidity, there must be at least 3 loops for each connection.

You can use the PVC tape gluing method:

- Glue one side onto lying plywood.

- Then fold it with another sheet and glue it folded so that the structure folds like an accordion.

- After joining the parts, roll the fabric to remove air bubbles (you can use a narrow spatula).

Use construction adhesive for gluing. But you need to act precisely, since PVC does not forgive mistakes. The fact is that PVC glue does not require correction when gluing, so you need to immediately accurately position all the parts. Preliminary marking will help with this.

After gluing, you can test the payol in action in a few days.

Important gluing details in the video:

DIY PVC boat floor. Manufacturing method and nuances.

Another interesting option for connecting parts:

Do-it-yourself floor (slan, payol) for PVC boats

We mount the PVC bottom on the boat

We place the floor inside the boat before pumping, after which we unfold our “accordion”.

You can install the slan into an inflated boat like this:

- Turn the assembled bottom with the desired side up.

- Place one end in its place, for example, in the bow.

- Straighten across the entire boat floor.

Now you can feel confident in the boat.

As you can see, making a hard bottom is quite easy. It’s even easier to immediately buy a boat with the desired bottom and not bother with the invention of the floorboard. And you can always do this in our store, which is already so loved by real fishermen!

Question answer

Question: How to make a good bottom in a PVC boat with your own hands?

Name: Egor

Answer: All parts of the bottom need to be cut out of a suitable material, processed and assembled into a single structure, for example, like a book or an accordion. The completed floor is placed in the boat and unfolded before pumping (it can also be done after).

Question: How to make reliable slings for a PVC boat?

Name: Ilya

Answer: The slan is the hard floor for the boat. But the parts of which it consists can also be called slans. Accurate measurements and drawings help to build them. We advise you to first make a pattern from linoleum, which will then be useful as a layer.

Question: How to make a completely rigid bottom of a boat so that it is convenient for fishing?

Name: Ilgiz

Answer: A hard bottom or floor can cover the entire bottom or part of it. In the first case, you need to accurately determine the dimensions. Also, for a really hard bottom, it is better to choose metal or durable plywood; you can make a floor with an H-shaped profile.

Question: How to adjust the size of floors on PVC boats?

Name: Egor

Answer: You need to measure the bottom of the boat. It is better to increase the width of the rectangular part by a couple of cm. A good, accurate drawing, which can also be drawn up using a computer, is important.

Question: What can be used to make a stable floor for a PVC boat?

Name: Ilgiz

Answer: From lath, plywood, metal. There are also options with an H-shaped profile, as well as a book-type sling.

Share link:

Types of PVC tapes for strengthening and armoring boats

If the purchased boat does not have protection, then it is necessary to strengthen the main places in such a way as this will preserve the integrity of the item longer. PVC tapes are used as armor, which come in several types:

- PVC profile 45mm with stripe, two-color;

- PVC profile 60mm monochrome;

- PVC profile 70mm with 2 stripes, two-color with rib;

- PVC 80mm with stripe, two-color with rib;

- PVC 90mm with 3 stripes;

- PVC 90mm with 3 stripes (mod.) Two-color with rib.

Tape to protect the reinforcement of the swimming device, used in all its places. In addition to the fact that it can be used over the entire bottom area, it is also suitable for the sides of inflatable boat cylinders. That is, it can be glued to any place that is subject to frequent friction.

When purchasing a swimming device, the future owner should study its characteristics, clarify the quality of the material from which it is made, and also see if there is protection. Quite often, manufacturers install additional armor, but this affects the cost of the product, so when purchasing a more expensive means of moving on water, it will most likely be additionally strengthened.

Attention: it is worth knowing that this material is not used on polymer surfaces, as well as those made of silicone.

Sizes and colors

The range of reinforcing tapes for boats is quite large, the size of the tapes varies from 35 to 235 mm in width, they are made of unreinforced dense PVC. The most commonly used tape sizes are:

- 55mm, it can be black or gray, the cost starts from 90 rubles. per meter;

- 60mm, colors also black and grey;

- 90mm, black and black colors, cost from 90 rubles;

- and 235mm it is usually only in black colors and its price starts from 200 rubles. per meter

In addition to tapes, you can use TPU profile and film.

Attention: since when water transport is strengthened, its total weight increases, it is necessary to take into account that PVC tape for boats may differ in density, and accordingly the weight after gluing will be slightly different. If the vehicle is not transported on a trailer, then lighter belts should be used.

Membrane armoring

The procedure goes as follows:

- before proceeding with the main activities, the boat must be thoroughly washed, dried, all small grains of sand must be removed and degreased with a solvent;

- after that, it is pumped up in order to make a template for cutting out the material, for this purpose it is turned upside down and dimensions are taken from the keel to the cylinders;

- then the material is cut out according to these measurements (it is advisable to prepare two identical strips) and left in the sun or put in a warm place so that it is leveled;

- then the boat is deflated, having pulled out the valve, laid out on level ground;

- one strip is placed to the bottom, leveled along its entire length, and they begin to heat it with an industrial hot air gun set to the maximum setting, while simultaneously rolling it with a roller in order to remove air;

- then perform exactly the same actions with the 2nd strip, placing it exactly next to the first.

The gluing procedure is carried out by heating the membrane by exposing it to elevated temperature. No glue is required.

Self-attachment of the fender beam

Independent strengthening of a PVC boat consists of the following operations:

- The boat is washed, after which all dirt is removed. After this, the boat is dried as thoroughly as possible. It should be remembered that the slightest traces of moisture will not allow the elements of the boat to be properly glued together.

- The surfaces to be bonded are degreased with gasoline or acetone. Degreasing is carried out carefully so as not to disturb the fabric.

- Using a brush, a layer of glue is applied to the surface. Typically the adhesive is applied to the boat and fender. After 15 minutes, a second layer of glue is applied. The layers dry until the glue stops sticking to your hands.

- The beam is placed on the surface and pressed.

- To ensure that the surfaces stick securely, it is better to heat them with a hairdryer. Heating is carried out very carefully so that the plastic does not start to melt.

- After this, the surfaces to be glued are again pressed with maximum force.

Do it yourself

The process of strengthening a boat occurs in several stages, and each stage must be done fairly quickly.

So:

- The boat inflates and turns upside down;

- is washed and wiped with a rag;

- The dimensions of PVC or rubber fabric are made from patterns or by eye;

- Using a rag and a solvent, remove grease from the boat , wipe the place of gluing and the material that will be applied;

- According to the specified dimensions of the patch, or rather along their contour, tape is glued to the boat so as not to stain the transport with glue;

- Before applying the glue , both the boat and the workpiece are heated with a hairdryer;

- The glue is applied to the boat twice. The first thin layer is given time to dry, but not dry;

- The second layer is the main one, applied within a reasonable range of 2–3 mm. He is also given time to dry out and become a little weathered;

- A very thin layer of glue is placed on the workpiece and covered in the intended place;

- At the discretion of the craftsman, you can warm up the boat while putting on the lining (if it has cooled down);

- Using a roller, the layer of fabric is rolled out , expelling all the air so that everything lies very tightly;

- With the help of a hairdryer, the fabric is heated and rolled out at the same time;

- Then, depending on the type of glue , the water transport dries for 2–3 days.

Anchor eye

It is installed at the stern of the boat and facilitates the process of lowering and raising the anchor. The roller is placed slightly lower to prevent abrasion of the fender.

Sources

- https://www.prospinning.ru/lodki-motory/502-zashchita-poverkhnosti-korpusa-naduvnykh-lodok-pvkh-i-dnishcha-polimerami.html

- https://wlooks.ru/lodki/bronirovanie-pvh/

- https://lakeking.ru/lodka/obustrojstvo/usilenie-dnishha.html

- https://spyship.ru/sovety/zashhita-naduvnoj-lodki-pvx.html

- https://lodka.vitur33.ru/

- https://FishingDay.org/tyuning-lodki-pvx-svoimi-rukami/

- https://TroeVLodke.ru/furnitura/dlya-lodok-pvh/usilenie

- https://VsyaKraska.ru/instrumenty/lenta-pvh-dlya-lodok/

Properties of polyurethane

The unique performance qualities of the material expand its use in various industries. These properties include:

- Flexibility - has good elongation and recovery characteristics.

- Wide range of hardness - this material is strong enough to protect the surface from damage.

- High load-bearing capacity - has high load-bearing capacity in tension and compression.

- Resistance – has high tear resistance along with high tensile properties.

- Abrasion and impact resistance - the material has good resistance to heat and temperature changes.

The main advantages of polyurethane film:

- High abrasion resistance.

- Does not deteriorate even at low temperatures.

- Wide structural variability.

- The cost is lower than other similar materials.

One of the most desirable qualities of polyurethane film is its ability to elongate. Polyurethane products are produced without the use of plasticizers, so they retain most of their performance characteristics over long-term use. Polyurethane film materials easily outperform many other common polymers when it comes to abrasion resistance.

Polyurethane film from Vitur https://www.vitur33.ru/production/plenka/ has excellent elasticity at low temperatures. Retains its flexibility even when exposed to very low temperatures down to -50ºС, easily surpassing PVC, which makes the film an ideal material for working in difficult conditions.

Polyurethane films have a high tensile strength. This strength allows it to outperform many other materials.