A spinning reel is a complex and at the same time delicate mechanism that greatly simplifies fishing using spinning, match and Bolognese rods. The product consists of a certain number of parts that interact with each other through the transfer of energy from the rotation of the mechanism handle by the fisherman. The device facilitates winding and feeding of the cord, and also, through the brake, eliminates unnecessary loads that arise during the process of catching and retrieving the trophy.

Often, the reel operates under very unfavorable conditions due to exposure of product parts to water and contaminants from sand and dust, which affects the service life. There is no doubt that the mechanism requires maintenance and one of the main operations to prevent breakdowns and guarantee reliable operation is the lubrication of spinning reels. It is this important event for the device that will be discussed in the further material of the article.

Nuances of processing multiplier reels

Fishermen should pay attention to the maintenance of multiplier reels, which should be done more often and more thoroughly than inertia-free versions of mechanisms. Due to the design features, the multiplier parts are located in a housing that is easier for dirt and moisture to enter, which can significantly reduce the service life of the product.

Important! The choice of lubricant for a spinning reel of this type is based on compounds that are waterproof and do not dry out quickly.

In addition, the bearings must always contain an excess amount of lubricant to prevent moisture and abrasive from entering the part. It is not enough to lubricate a spinning reel once a season; the multiplier is inspected and checked for the presence of lubricants after each intensive fishing.

Silicone grease with Teflon for long-term operation. OKS 1148.

Silicone grease with Teflon (PTFE) for bearings that require low rotational resistance at the beginning of operation at low temperatures and which are further exposed to temperatures from +150C to 200C. Silicone grease with Teflon has excellent resistance to steam, animal, vegetable and mineral oils, as well as acid fumes. There are a huge number of silicone lubricants and from them you can choose one that is suitable for our reels in all respects and is inexpensive. I gave just one example above. Absolutely indifferent to water - the main plus. Well, etc.. Only one thing is not available - how they behave in the ball bearing of the line roller. Apparently they forgot to write in the annotations for lubricants. :)) You need to test it yourself...

There is also a CV joint, which is often mentioned in forums. But here’s a post I once came across in the same place: From faq to lubricants: CV joint 4-Lithium grease with a molybdenum disulfide content of at least 10%. Shelf life 5 years. MoS2 (molybdenum disulfide) is a very unique thing that holds enormous loads in the friction unit.

But only a naive person can pour molybdenum into his engine. After all, I missed the moment of changing the oil a little and the engine was in trouble. Why? Because the oxidation products of molybdenum disulfide consist of molybdenum oxide (MoO3), which is highly abrasive, and sulfur, a corrosive agent. This is very clearly visible when the boot on the CV joint breaks.

The CV joint fails, not because dirt got inside, but because disulfide decomposes under the influence of oxygen. Ingress of moisture aggravates the situation, as it produces sulfuric acid (H2SO4). Acid softens the metal, abrasive causes wear. That's it... And on the same subject, for general information and as a food for thought... On lubrication of coils and instructions for coils. According to the general rules, open-type bearings are filled with thick grease, not oil. Oil is used only as an additive for sealed bearings. And even then, it is not recommended to do this - the lubricant should be enough for the entire service life. Has anyone ever lubricated the bearings in a car with oil? Hard to imagine. And here is an almost open unit, accessible to water and everything in the world, rotating at speeds of up to 3000 rpm. per minute - and liquid oil. The accepted argument is ease of rotation. But let's take a car wheel as an example. What, it rotates heavily in weight? Yes, it can spin for five minutes! And the loads are heavier. And the lubricant is thick. In short, a reason to think about those who lubricate their rollers with thin oil... And special ones... Of course, they are essentially the best and right choice if you have them and you are confident in it. But I can’t imagine what’s so fancy and unusual about Shimano lubricant that costs 800 rubles for a meager tube. You can, of course, not take Shimano. It’s not like Shimana alone is alive with reels. There are also a variety of lubricants in the middle price range. But what kind of quality is there again? Personally, I trust our modern CIATIM more than some Malaysian packaging with the “correct” signature “fishing”.

Care and prevention of breakdowns

During the fishing season, any mechanism is repeatedly exposed to harmful effects from excess moisture and sand entering the body, which destroys the working surfaces of interacting parts. It will not be possible to avoid these negative impacts even with the most scrupulous attitude towards the product. Prevention of breakdowns and care of the device consists of lubricating the mechanism and cleaning the internal and external surfaces of dirt.

To prevent the coil from failing, preventative maintenance must be performed at least once a year. After all, even an infrequently used mechanism is prone to natural drying of lubricants and corrosion of the metal surfaces of working parts and connecting elements that arise from the presence of moisture in the air.

When, with what and what to lubricate

Spinning reels require periodic inspection to determine if lubrication is required. Typically, the need to carry out this procedure arises in the following cases:

- The device falls into the water and gets wet.

- Sand particles entering the structure.

- The presence of dirty oil on the axle, which can be identified by its darkened shade.

- The beginning of a new fishing season.

- The middle of the fishing season, if the reel is in active use throughout the year.

Inspections and lubrication are carried out as a preventative measure 1-2 times per season; you should not wait until the reel fails due to insufficient care, since in such situations it is not always possible to repair it.

Sometimes fishermen use solid oil or usually machine oil for such purposes, but such maintenance can only worsen the condition of the gear.

A much safer option is to use special lubricants, the main types of which are given below:

- Thick specialized lubricants are designed to care for bearings and gears , since they do not drain from them.

- Liquid specialized lubricants that are suitable for maintaining the shaft and rotor.

- Universal mixtures that can be obtained by mixing liquid and thick lubricants in equal proportions.

The use of thick lubricants is usually required when significant friction occurs in parts, but it must be remembered that products with too thick a consistency are prohibited for use. They can make the situation worse by making the reel travel too tight, making it difficult or impossible to operate.

When is lubrication needed?

In addition to the mandatory inspection and maintenance of reels before the start of a new fishing season, the mechanisms require emergency cleaning and lubrication when a number of situations arise that may subsequently negatively affect the performance of the product. This type of force majeure includes a long-term stay of the product in water, when there is a high probability of filling the case with moisture. Also, getting sand and dirt onto the working parts of the device and inside the body will not contribute to the correct operation of the reel on your next fishing trip.

You will also have to lubricate the spinning reel in cases where intensive fishing was carried out, involving forceful fishing of fish and frequent operation of the mechanism caused by the dynamics of the retrieves, especially heavy baits. Timely maintenance will keep the inertia-free unit in working condition for a longer period of time.

When and why to lubricate?

Any reel is a rather complex mechanism, consisting of many parts that interact with each other. During fishing, water and various types of pollutants can get into both the outer surfaces and inside this mechanism. To avoid its failure at the most crucial moment, it is necessary to disassemble and lubricate it. Ideally, you should inspect the reel after each fishing trip to assess the degree of contamination and identify possible damage. This inspection will help determine whether the mechanism requires servicing.

Lubrication of Shimano fishing reels, like all others, is carried out if the tackle fell into the water or lay on sand or on the ground, as a result of which grains of sand and other contaminants got inside.

In addition, it is imperative to lubricate the reel before the start of the fishing season, in the middle, if the reel was actively used in different modes, and at the end of the season, when sending the gear for storage.

How to lubricate a spinning reel

In theory, ordinary machine oil and even solid oil can serve as a lubricant for coils, but in practice, to maintain optimal performance and ensure effective protection of the working surfaces of rubbing parts, it is better to use special lubricating compounds. These compounds are developed by reel manufacturers. Almost every brand has its own developments in lubricating compositions, which are offered for servicing the device upon purchase, which is worth using. In terms of consistency, lubricants can be liquid - for treating rotors and coil shafts, as well as thick - for lubricating gears and bearings.

One of the features of fishing reel lubrication is the versatility of certain types of compounds that are intended to treat the entire mechanism as a whole. Recently, effective silicone lubricants for inertia-free and multi-action machines have appeared on the market in the form of aerosols, which are much more convenient for servicing mechanisms.

Spinning reel care. How to lubricate and clean a reel

Caring for a spinning spinning reel. Lubrication, cleaning the roller I am an avid spinning player. Naturally, I have been dealing with spinning tackle for many years, and one of its main elements – spinning reels. The reel is a high-tech, complex mechanism. This means that it requires special care in order for the reel to serve its owner as long as possible. Today I want to talk about preventative care for your spinning reel.

I'll tell you right away. If you have a new high-end reel, then if you use it carefully, there is no point in getting into it at all for the first season. Unless you dropped the tackle in sand or mud. Then you will have to partially or completely disassemble the coil and lubricate it.

So, the simplest preventive inspection and cleaning. You need to loosen and completely unscrew the friction brake screw and remove the spool.

Unscrew the clutch screw

We inspect the coil. Remove dust, sand, dirt from the surfaces of the reel and spool using a soft cloth.

Carefully remove sand from the spool. Wipe the inside of the spool.

In the first season or two, it is better not to interfere with the lubrication system of the reel. If the movement becomes difficult, you can drop 1-2 drops of liquid machine oil onto the spool axis and rotate the reel several times so that the lubricant goes into the mechanism.

The spool is removed

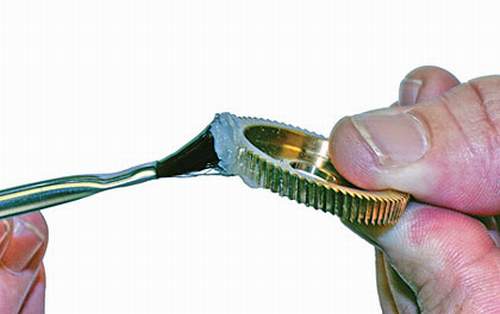

Problems often arise with the line roller of the spinning reel. There should be no disruption in its operation. The roller must rotate properly, otherwise it will simply be sawed through by the cord. So, periodically you need to unscrew the screw that holds the roller.

Line roller

Unscrew the screw of the line roller

Carefully remove the video. We wipe everything from dirt and sand. Lubricate it if necessary and put it back together.

You can also remove the reel handle to clear any dirt or sand from this connection.

Removing the reel handle

Here you can lubricate the two bearings on which the reel handle is mounted.

In general, I do not recommend further disassembling the coil unless absolutely necessary. In the case of high-quality, expensive reels, the need for complete disassembly and lubrication of the mechanism itself arises no earlier than the 3rd season or does not arise at all... I have an old Abu Garcia reel. So she’s already 7 years old and I’ve never taken her apart - the move is perfect! So, if you want to climb, it’s better not to climb.

Purely technically, to get to the mechanism, you need to remove the rotating base of the line guide.

Removing the line layer

We disconnect the line guide and then unscrew all the screws on the body. Here's the mechanism.

After 2-3 years of operation, you can completely change the reel lubricant. Then half measures will no longer work. You need to completely disassemble the coil. Wipe off the remaining old grease from the parts, wipe the metal elements of the reel mechanism in gasoline or kerosene. And lubricate the mechanism with special lubricants provided by reel manufacturers.

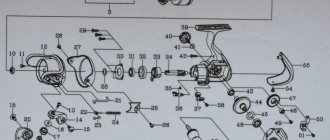

It is clear that there are as many manufacturers and models of reels as there are so many nuances in disassembly. In this review I have reflected general points that are common to most reels. There may be some other fastener, screw, clamp, etc. somewhere. If the ways to disassemble the mechanism are not obvious at first glance at the reel, then see the disassembly diagram in the instructions or on the reel manufacturer’s website...

Z.Y. If the season is over and you are putting the reel in a case for the winter, it is advisable to completely loosen the clutch adjuster screw. This will extend the life of the friction brake!

Read other articles, reviews and testimonials:

- How to look for pike in November on rivers and ponds. Pike stopping places in November

- Review of the Favorite Balance spinning rod. Reviews from fishermen about the Favorit Balance spinning rod

- How to choose a rattlin that will catch pike perch?

- How can you catch pike perch? Where to look? Basic methods of catching pike perch

- Review of the Jackall Mag Squad 128 SP wobbler. Reviews from anglers about the wobbler Mag Squad 128 SP

How to disassemble a spinning reel

In order to disassemble the reel, the fisherman will need a certain plan of action and a small set of tools. Disassembly work is best done on a table covered with a clean sheet of white paper, on which the parts of the product are better visible. Good lighting is also necessary. The tools that will be in demand are: Phillips and flathead screwdrivers, tweezers, pliers, a brush, a large sewing needle, an old toothbrush and a household hair dryer. It’s also worth stocking up on pieces of soft cloth to wipe the parts and body from old grease and dirt. To wash the components of the device, you need to have kerosene or a small amount of gasoline.

Important! Disassembly is carried out with sequential unfolding according to the order of dismantling the removed parts - these actions will ensure error-free and accurate assembly of already serviced and lubricated elements.

Preparing for the lubrication process

Lubricating a spinning reel with your own hands requires careful preparation of the workplace, tools, auxiliary materials, etc. You will definitely need:

- A piece of clean soft cloth;

- Screwdrivers of appropriate sizes (Phillips and flathead);

- Tweezers;

- Wrench;

- Soft brush and thin brush for more thorough cleaning of parts;

- A little gasoline to remove dirt. Gasoline for lighters is suitable;

- Toothpicks. They can be useful for cleaning old dirt in secluded places;

- Lubricant for spinning reels.

It is very important to create good workplace lighting . The working surface of the table on which the fishing reel will be lubricated must be light. On such a surface, small parts of the mechanism are much better visible. Some fishermen use regular paper of appropriate sizes for these purposes.

You also need to decide in advance what kind of lubricant you will lubricate the spinning reel with. You can find out how best to lubricate a fishing reel from the instruction manual that came with it, or from a specialist in a fishing store. The best lubricant for fishing reels is exactly the one recommended by its manufacturer.

Lubrication sequence

We begin the work slowly, remembering the order and principles of removing the components of the product. First, remove the handle and unscrew the clamp holding the spool. Next you need to remove the bushing with bearings and a set of adjusting washers. Having carried out this operation, they begin to dismantle the overrunning clutch. The removed parts are wiped with a cloth and cleared of debris using a needle, sequentially placing the elements of the mechanism on the table. Next, unscrew the anthers, also subjecting them to thorough cleaning of grains of sand and other contaminants. Now the fisherman has reached the heart of the mechanism, namely the gearbox itself. The box is removed from the body using tweezers.

Having marked with a marker the location of the gears relative to each other, we begin to remove them. We take out the carriage stopper and the carriage itself. We take out the axle and one of the gears of the main pair. After this manipulation, you can easily clean and lubricate all parts. After removing the remnants of old grease and visible blockages, the parts are washed in kerosene or gasoline, wiped with a cloth and dried with a hairdryer. After drying, lubricate and begin reassembling the device.

Grease is applied to the bearings and shafts during the direct connection of the mechanism elements. Experienced fishermen who have dealt with servicing reels more than once perform all the above operations within an hour. A beginner will need much more time and diligence to complete the work, and for accuracy of assembly, we recommend that you accompany the operations with photography to facilitate the reverse assembly process and eliminate installation errors.

Correct lubrication algorithm

A lot has already been written and said about how to properly lubricate a spinning reel. Every experienced fisherman has his own little secrets on how to do this faster and more efficiently. Here is the correct sequence of actions that will help you lubricate your fishing reel simply, without wasting extra time:

- First, conveniently place on the table everything that you have prepared for this process: tools here, lubricant for the reel there, rags and a brush next to it, etc. Lubricating spinning reels does not tolerate fuss.

- Next, the disassembly of the mechanism begins:

- Release the bobbin and unscrew the handle.

- Carefully remove the bushing on which the shims and bearings are located. This will be easier to do with a thin screwdriver or toothpicks.

- Unscrew the bolts holding the overrunning clutch cover.

- We remove the coupling from the needle type bearing. Gently wipe them with a soft cloth, freeing them from dirt and old grease.

- We unscrew the anthers with a screwdriver and remove them, after which the cover is completely removed. Place all extracted parts and elements on the table in a certain sequence.

- We use a marker to mark the main pair of gears. This is necessary for accurate reassembly of the mechanism.

- Using tweezers, remove the stop box.

- Next, remove the carriage, first, using tweezers, dismantling its stopper.

- Now you need to remove the completely free axle and the second gear of the main pair.

- That's it, disassembly is done. At this stage, it is strongly recommended to photograph all the parts; this will help later, during assembly, not to get confused in the order of their installation.

- Now comes the stage of cleaning all internal parts of the mechanism from old grease and contaminants. The easiest way to do this is to place them in a container with gasoline.

- While the internal parts are soaking, you should use toothpicks, brushes and a soft cloth to clean the body elements.

- Next, all parts are cleaned, after which they need to be dried so that the lubricant for the spinning reel is placed on a clean surface.

- The next stage is the assembly process, during which the spinning reel is lubricated. We decided in advance how to lubricate the spinning reel, the main thing now is to do everything carefully.

- After assembly, it is necessary to check the operation of the mechanism. Pay special attention to the bow closure assembly. It should also be lubricated and operate without delay.

- If everything functions as it should, then you did everything right.

The described process, of course, is not very simple and painstaking; it requires concentration and attention, but how to lubricate a spinning reel without disassembling it? Complete lubrication without disassembling and reassembling the mechanism will not work. It is only possible to treat the line guide arm and the outer bearing with a high-penetrating silicone spray. But this will be a temporary measure.

How to lubricate the reel clutch? This is a common question among spinners. For the friction mechanism , some manufacturers produce a separate type of lubricant . If you don’t find one, some experienced fishermen advise, after cleaning it from dirt, to rub its surface with rosin. But any waterproof grease will work.

Is it possible to lubricate the coil without completely disassembling it?

Beginning fishermen especially often wonder whether it is possible to lubricate a spinning reel without disassembling it. The question is relevant for a beginner, since each reel differs in the structure and design nuances of its assembly, and only a specialist can competently service the mechanism. But, unfortunately, it is worth noting that without opening the case and removing the component elements of the product, it is not possible to clean the mechanism and effectively service it.

Important! Aerosol sprays only partially relieve the lubrication problem, without eliminating the consequences of clogging of gears and gearbox shafts.

If a fisherman is unsure of his ability to properly service the device, the best option would be to trust the service departments or more experienced fishing colleagues in this matter, who perform the work efficiently and without loss of reel performance.

Reel Lubricant

Do not use grease as a thick lubricant.

Use specialized thick and liquid lubricants for reels. On sale you can find lubricants for reels from specialized fishing companies: Abu Garcia, Daiwa, Shimano, Ryobi, Tica, Mikado, SFT, etc.

It is better to use lubricant from the same company that manufactured the reel.

For example, Shimano produces a special grease designed for the main pair, mechanisms and bearings. Its viscous structure reduces friction, increases reel life and makes reel operation smoother.

The price of reel lubricants ranges from $2 to $100, depending on the brand and volume.

Preparatory stage

Before starting any work with spinning reels, you must properly prepare your workplace. It will be necessary to provide high-quality lighting, and it is advisable to choose a light surface, as this minimizes the risk of losing the smallest details.

You also need to make sure you have the following tools and materials:

- Cotton napkins or a piece of soft cloth.

- Phillips and flathead screwdrivers.

- Wrench.

- Tweezers.

- Set of toothpicks.

- Gasoline, which is used to refill lighters. You can also use automobile fuel, but the process will be much more complicated, and it also has a more pronounced odor.

- Selected variety of specialty reel lubricant.

- A universal marker that can write on any surface.

- Thin brush with soft bristles.

- Small glass jar or other suitable container.

Main pair of coils and bearings