Feeder fishing is quite popular among anglers; many prefer to put out their rods and, while enjoying the sun, wait for a bite. You can also fish at night with the feeder; this tackle is suitable for the nocturnal inhabitants of our reservoirs.

Assembling feeder gear is not difficult; every self-respecting fisherman knows the basics. A rod, reel, fishing line - all this is selected individually, but with feeders you should not rush and buy what you like visually. This issue is worth studying in more detail, since a correctly selected feeder for the feeder is the basis for successful fishing.

Feeders for ponds and lakes

Standing water will require lighter equipment; for this, spring-shaped feeders are often used. Depending on how much bait you need to throw, the following types are used:

- “watermelon” or “pear”;

- a regular coil spring;

- flat method.

“Watermelons” and “pears” are often used to catch large carp and silver carp; these types of fish require a large amount of bait. A twisted spring is rarely used alone; most often, three such feeders are used to form a floating “crucian carp killer” tackle. This method is often used to equip feeders for catching carp and large crucian carp, but such fishing requires preliminary feeding.

The three-rib feeder is used less often by fishermen; carp catchers prefer it because no matter how the cast is made, the bait always ends up on top. This product is perfect for creating equipment for boilies.

For boilie rigs, do not use flat-method feeders; there is not enough bait in them, and constant casting can spook the fish.

Victoria Leshchenko

I've been working hard in the fishing tackle department for the past six years. I can help you assemble almost any gear.

Ask a Question

For standing water, they are collected into a sliding tackle, which is secured with special beads.

Tackle

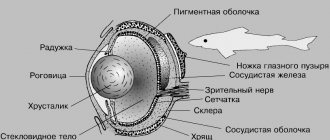

The tackle itself is built on the basis of a feeder rod. In essence, this is a feeder with only a floating feeder. Here are some characteristics of its equipment elements.

- Rod. For carp fishing you need a reliable form about four meters long.

- Coil. Either a regular feeder or a carp with a baitrunner.

- Cord. Braided line with sufficient strength for carp fishing.

- Shock leader. A piece of monofilament floating fishing line is about ten meters long and has a diameter of 0.27-0.30 millimeters.

- Float feeder. A floating feeder without additional loading, which is easy to make with your own hands.

- Leash. A piece of monofilament with a length of forty centimeters, depending on the depth of the reservoir: the shallower, the shorter and vice versa.

At the end of the leader's shock, Mr. Findlay puts on a swivel with a carabiner and knits a loop thirty centimeters long, so that the carabiner is inside the loop. A leash with a diameter of 0.16-0.18 millimeters in diameter is attached to this carabiner using the “loop-to-loop” method, and the keel of the float-feeder is also attached here.

Feeding trough

Feeders for feeding are used as auxiliary ones; sometimes additional rods are used to cast them. Most fishermen shape their gear so that they can easily change the feeders they use.

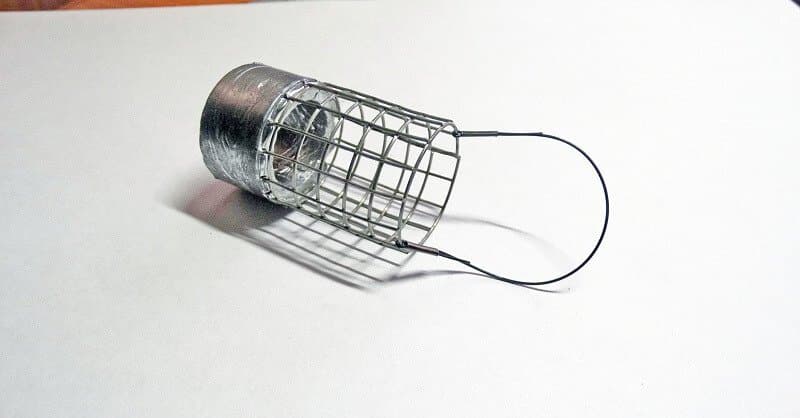

To add a large amount of feed, it must have the following characteristics:

- big sizes;

- metal mesh;

- lack of bottom;

- rare rods.

It is these indicators that will allow you to add the required amount of bait to the right place and quickly leave it there. Often feeding options are made with your own hands from old unnecessary household items.

In England, where feeder fishing is very popular, in practice a special method is used for feeding. A special design has been invented in which, after contacting the bottom, the structure squeezes out the food.

To feed animals with food, cork feeders of closed, open and semi-closed types are used. They differ from the rest by large holes throughout the body, through which the contents are washed out.

Let’s take a closer look at each type of feeder and find out their advantages and disadvantages.

Design features of the feeder feeder

When choosing a feeder, the angler needs to take into account its design features and be able to compare them with the conditions in which it will be used.

Weight

One of the primary indicators is the weight of the structure. The flight range of the equipment and the reliability of holding the hook with bait at the fishing point depend on this parameter.

When fishing on a pond or shallow river with a weak current, use feeding structures weighing 10–40 g (excluding food). They allow you to cast at a distance of up to 40 m and quickly descend to a depth of 2–3 m.

Weight parameters are indicated on the lead weight.

The weight of the bait element for fishing on large lakes and reservoirs should be 40–80 g. This option will quickly sink to a depth of 8 m and will allow you to make long casts in a headwind. A weighty feeder will keep the equipment on the point even in strong waves.

The heaviest models are used for fishing on fast rivers. Their weight can reach 120 g. Such products are securely held on the ground even under the pressure of a strong flow of water.

Capacity

The capacity of the feeder refers to the number of animal or plant components that can be placed in it. When determining this parameter, you should be guided by:

- the activity of the fish at the time of fishing;

- depth at the fishing site;

- the nature of the reservoir.

If the feeding activity of fish is low, it is necessary to use structures with a volume of up to 40 ml. Otherwise, underwater inhabitants can be overfed, and they will stop paying attention to the bait.

When fishing in shallow waters, you should not use models whose volume exceeds 50 ml. More massive options will create a strong splash upon splashdown, which will alert the fish and negatively affect the bite.

The volume of the feeder used largely depends on the nature of the reservoir. When fishing on a fast river, the bait mixture is washed away by the current, which requires the use of models with a volume of 50–100 ml. In stagnant reservoirs this figure is halved.

Metal or plastic

Feeder fish feeders are usually made of metal or plastic. Metal products have a number of advantages:

- have good aerodynamic properties, which contributes to long and accurate casting;

- better resist the directed flow of water when fishing in the current and reliably hold the equipment;

- allow the feed to erode faster.

Made of metal

The disadvantage of metal products is their slow ascent to the surface when landing fish. This leads to the structure getting caught on steep underwater edges and drops, which often ends in the equipment breaking. When fishing on rocky ground, metal models can become deformed - this negatively affects the casting distance.

Plastic products are more durable and do not rust. They float to the surface faster when reeling in the reel and cling less to underwater edges. The wide ribs of the plastic structure do not get stuck in soft muddy soil.

Plastic structures are not subject to corrosion and are more durable.

The flight characteristics of plastic products are slightly worse than metal ones, which reduces the casting range. Due to their wide ribs, plastic models resist flow less well, so they are more often used in standing reservoirs.

Metal or plastic?

Metal feeder

0%

Plastic feeder

100%

Voted: 3

For current or standing water

Some manufacturers give feeder feeders an original shape and equip them with spikes, claiming that this will help the structure more reliably stay on the bottom soil under the pressure of the current. Such statements are not true. Additional elements only complicate the fishing process, reducing the casting distance and collecting debris.

For fishing in the current, it is better to use classically shaped feeders with a flat weight. It is desirable that the structure be made of metal.

In stagnant bodies of water, plastic products have proven themselves better. When fishing on lakes, ponds and reservoirs, the feeder should focus not on the shape, but on the volume and weight of the feeder.

Feed washout rate

When the feeding activity of the fish is high, the feeder needs to ensure that the feed is washed out as quickly as possible. This can be achieved by using metal models whose body is made of thin wire. When using such feeders, the attracting components begin to wash out immediately after the structure splashes down, creating an appetizing column of turbidity.

Feed is washed out more slowly from containers with a bottom.

When fish are inactive, they can become oversaturated, so the amount of food washed out should be small. In this situation, plastic products with several holes on the body are used. In this case, the bait is mixed with soil and compressed tightly.

Rectangular feeders with soldered weights

Feeders made of rectangular or square metal mesh are used for feeder fishing on the river. Their bottom is flat, and there is a soldered weight of different weights on it. Previously, it was believed that this particular feeder was most suitable for the current; it supposedly did not get carried away by water. Additionally, spikes were made on the bottom, which sink into the ground and thereby better hold the feeder in place. It has now been proven that spikes do not allow achieving the desired result; in a strong current, a feeder with a small weight will still be carried away.

Among the disadvantages of metal rectangular feeders, it is worth noting the following:

- after washing out the food, they rarely float up due to the sinker;

- when casting, after contact with water, they produce a strong slap, which can scare away the fish;

- when pulled out, they often cling to bottom irregularities, the process is slowed down by water.

But for some, this view is still the best. The classic is more in demand among experienced fishermen.

Installation of feeder with feeder

There are a lot of methods, but the reel always has a lead sinker.

Nowadays you can easily find suitable forms and devices for pouring in fishing stores. Ready-made loads are also on the shelves. But those who are preparing a “sleigh in the summer” will be interested to know what types of feeders there are, what needs to be taken into account when making them. When making feeder feeders from a metal base, you can make a mold for casting them in advance. For example, cut out a base in a wooden beam or make a plaster mold (first make a model of the sinker, and then make the base of the tackle from it).

As in the case of a wooden universal model, mesh or wire fibers, laid properly, are placed in the recess. Lead is poured in such a way as not to touch the installed elements. Afterwards, the workpiece is adjusted to the required size, biting off and filing away the excess. The actions with the gypsum universal form are similar.

Before soldering, it is better to tin the remaining elements of the feeder with rosin and coat them with flux. A mesh and eyelet are soldered to the workpiece.

DIY floating feeder for feeder

A homemade device that stays afloat is suitable for cases when fish feed mainly in the upper layers of the reservoir.

You will need:

- mesh or plastic cylindrical cone;

- leash 0.5 m long;

- foam sealant;

- carabiner type lock;

- a piece of thick wire;

- heat shrink.

We tie the edge of the cone, press the rod, fix it with foam, remove its excess. We glue the structure and paint it. We attach a clamp with a rein to the wire, tie a carabiner to a loop of fishing line 0.4 m long.

Calm weather is good for fishing with this type of gear.

You can make plastic tackle from any tube-shaped plastic object. Kinder capsules, women's curlers, bottles, cases, car parts, filters and much more are well suited. Their undoubted advantage is their low weight and ease of storage. They will not take up much space in a fisherman's chest. They are also relatively easy to assemble and not expensive. The only downside is its fragility, but it is justified by the low costs.

You will need:

- bottle;

- lead rod;

- paper clip;

We cut off the edges of the bottle with a stationery knife and cut it lengthwise. With a pencil we mark the places for the cells and burn them with a hot nail. We clean the uneven areas with sandpaper. We roll the workpiece into an arc, overlapping one edge over the other, and glue it. We adjust the metal plate to size and fix it. We make a ring out of a paper clip and fix it.

Photo printing machine filters are a mesh tube and are perfect for making a feeder.

You will also need: lead, wire, the workpiece itself. The technology is the same.

Akafish - a fish feeder is needed to lure prey to the right place. Types of feeders by purpose:

- for the first feeding - with large cells, so that the food is washed out by the current and spread over a large radius, luring fish from the far corners of the reservoir;

- shuttlecock feeders, due to their good aerodynamic characteristics, fly easily and far;

- feeders for standing water, with large cells, but a shorter range;

- feeders for currents, with a flat base, a weight, made with small holes;

- for live bait (larvae, worms, maggots)

It will serve you for a long time due to the durability of the mesh. To make it you will need: the mesh itself, a weight, and wire. We cut a rectangular piece of mesh, twist it, and bend the ends. We attach the sinker and the wire ring.

To assemble such a feeder you will need:

- pen;

- film container;

- two-way spring.

The edges of the spring are clamped to the size of the case (up to 6 mm). The plastic part is removed from the case and a spring is inserted inside. Next, several centimeters of lead are poured onto the bottom of the case. The spring will hold tightly in the case, and the structure will not crumble when casting. Next, in the middle of the case we make a hole for the pen, insert it and melt the tip.

We make another small hole at the bottom of the case. We blow through the tube and insert the fishing line into it, bringing it out through the hole at the bottom. We place the piston in the case so that it does not protrude beyond the edges of the case. The tube should protrude 4-5 mm beyond the case, cut off the excess.

We press on the piston and pull out the tube more. Melt the tip. We get a roller distributed along the cut of the tube. We press in the piston. If you were unable to find a film container, you can use a Kinder Surprise container.

Feeder feeders differ in weight, size, shape and feed capacity. Each fisherman himself chooses which model to fish with: light, heavy, streamlined or bulky. A standard feeder includes the following elements:

frame;- sinker (flat, bullet-shaped, etc.);

- eyelet, ring or swivel for mounting on equipment.

Manufacturers use different materials to make the case. It can be plastic, metal or made of nylon mesh. By the way, the latter is rare today due to its catchiness. The sinker is most often a plate made of a heavy alloy or lead. Some metal feeders designed for fishing in still water are heavy enough on their own for long casting, so they do not require additional weight. An example is the so-called spring, which is used to catch carp in carp ponds.

We suggest you familiarize yourself with: Inline installation for a feeder on a braided line

You can make a completely working feeder with your own hands from scrap materials. You just need to find a piece of metal mesh, wire with a diameter of 1 mm and a little lead. The mesh is given the desired shape and inserted with its ends into a square recess made in damp sand. An ear is bent from the wire and also inserted into the recess on one of its sides.

From curlers

Below are options for installing a feeder with a feeder using various mounting methods.

The following factors influence the use of feeder feeders:

- Distance to point.

- The weather, or rather the wind.

- Depth and current.

- Specific fishing tasks by type of fish, characteristics of the consistency and composition of bait, tactics.

- Installation and equipment of feeder gear.

You can make feeders for feeder fishing yourself. The simplest option is to attach the desired weight to the plastic curlers with screws or rivets. The cage can be rolled up from metal - mesh or a solid sheet, followed by drilling holes. The design can be anything - the main thing is to adapt it to the fishing conditions. For successful fishing, you need to comply with the features that are described in detail at the beginning of the article. Read more about homemade feeder feeders.

Knowing certain criteria for the planned fishing session, you can design and then build a feeder for the feeder with your own hands without much difficulty and expense. Fortunately, the material for making bait devices is in abundance nowadays and, to a large extent, you don’t even have to buy it.

The main difficulty in production is the manufacture of cargo, which will require, albeit primitive, but still a certain metallurgical process associated with casting molten metal, mostly lead, into the form required by volume. The casting mold is prepared from gypsum, and the lead is melted on a gas stove, observing safety rules when working with hot processes.

All homemade feeders are distinguished by their exclusivity, and we will talk about some options for their production separately, focusing on the choice of material, its processing and the required technological operations for assembling a tool ready for a fishing session.

This is one of the simplest and cheapest ways to quickly and efficiently make a feeder for a feeder. To work, you will need an ordinary plastic bottle, without any kind of imprint on its surface. The neck and bottom of the bottle are cut off. This produces a cylinder of pure plastic. Having decided on the size of the future accessory, we cut out a strip of plastic of the required size and twist it into a cylinder, connecting it with wire stitching, which is taken by straightening an ordinary paper clip.

After manipulating the load, a hole is formed for the winding ring to be attached to the equipment and perforation is arranged. Perforation can be done by burning or drilling holes of the required diameter.

Homemade feeder feeders made of metal mesh are also common in fishing. For the most part, accessories are made of parallelepiped geometry with open or closed ends. To produce such a homemade product, you will need to purchase a metal mesh and preferably a galvanized version with a cell no larger than 5x5 mm. To make a dozen products you will need no more than one square meter of mesh fabric.

Weights, as in the previous version, are used from a set of lead plates as needed for the conditions of the reservoir. From a canvas cut with metal scissors, a shape of the required size is formed by bending the sides of the figure using a mallet. The connection point is soldered with tin or fastened with a wire broach.

"Bullet" or "rocket"

This type of feeder feeder is increasingly attracting fishermen, although previously it was considered impractical to use “bullets” in the current. Recently, the views of even fishermen with experience in this matter have changed; increasingly, the “bullet” is used to equip a feeder for the river. These feeders are characterized by:

- plastic case;

- the presence of wings on the sides;

- cone-shaped body;

- weight at the very end of the feeder.

Among the disadvantages, rapid wear and tear is noted; plastic, when exposed to water and sun, quickly loses its structure and becomes more fragile.

But there are more positive qualities:

- after washing out the bait, the feeders float up perfectly;

- thanks to their shape they fly further and better;

- when in contact with water they do not create unnecessary noise.

The equipment turns out to be dull, but when you wind up the fishing line or cord, due to its shape, the feeder glides perfectly in the water column and practically does not cling to anything.

Feeder equipment and fishing conditions

First of all, there is a division according to fishing conditions. Depending on the reservoir, different fishing rods and equipment are used. It depends on where the angler spends more time. If these are small crucian carp ponds and small rivers, you will need a light rod with a test weight of up to 60 grams, or a picker. On large rivers, such as the Volga, you cannot do without Heavy-level gear, with which you can throw heavy feeders (120 grams or more) at a distance of 60-100 meters. Lighter weights simply will not be able to withstand the force of the current.

A universal equipment option is medium, medium feeder, rods with dough up to 90 grams and a length of 3.3-3.9 meters. This is a good first tackle option for a beginner. This rod will allow you to fish in crucian carp ponds and at distances of up to 80 meters on medium rivers.

After mastering it, you can diversify - buy and equip it, for example, with a picker for short-range fishing and a heavy one for difficult river conditions or targeted flat fishing of large carp with long casting. Therefore, we will continue the conversation about equipment, based on the average medium feeder, making reservations for extra-light or heavy equipment. An article about rods for feeder fishing.

- Advice for beginners is to thoroughly study the theory of the feeder. Store shelves are bursting with a variety of goods. You can buy a lot of unnecessary things, and then it will all be uselessly lying around in the corner of the garage. To properly equip a feeder, not much is required to begin with.

- At a minimum, this is a medium-class rod with a matching reel (a spinning reel with a spool size of 4000 and a gear ratio of 4.8-5.2). The feeder is equipped with a good braid of 0.1-0.14 mm (or monofilament about 2-0.3 mm) with a length of 120 meters or more. The usual distance for a feeder is up to 90 meters plus a margin. The kit also requires several different feeders, 0.25-0.3 mm fishing line for knitting rigs, thin monofilament for leashes and hooks.

- When fishing, you will need groundbait and bait (at least maggots). You can install the feeder on a wooden flyer, and measure the bottom with a working feeder. The entry level is several thousand rubles. This is five thousand for a more or less normal rod and reel plus small things. And these are not tens of thousands for top poles, which the authors of YouTube videos love to praise. In principle, a budget feeder stick is no more expensive than a set of 3-5 donks, but exceeds them in functionality.

- Anglers who are looking for information on the feeder and its equipment are usually not beginners at all, since they have a fair amount of experience in bottom fishing. Therefore, we will not limit ourselves to superficial calls to switch to a feeder, but will take a closer look at how to equip a feeder fishing rod. Having imagined in your head the general appearance of the feeder equipment, its elegance and capabilities, any experienced fisherman will understand the beauty and advantages of the English donkey over the usual one.

More details - reels for feeder tackle.

Triangular feeders

This type of feeder is considered a relic of the past; many fishermen have abandoned their use. The main reason for this was the small capacity of the feeder body, and the food was washed out of it quite quickly. In addition, due to its shape, the feeder falls heavily into the water and comes out of it the same way.

Characteristic features are:

- triangular shape;

- metal carcass;

- There is a soldered weight on one of the planes.

Previously, it was believed that such models held best in the current, but now they no longer argue about this.

How to make a feeder with your own hands

This gear consists of:

- plastic bottle cap;

- fishing lines;

- lead cargo;

- stopper, leashes (2 pieces, 0.4 cm each);

Drill a hole in the bottom for the fishing line and thread the leash. Attach a carabiner and a swivel to it on one side, a stopper on the other (it will make it easier to replace the leash in the future), attach the ring as in the picture.

We suggest you read: How to deliciously salt red fish

From curlers

The feeder feeder can be made in various geometric shapes, the main requirement is the possibility of a useful volume that can accommodate the amount of complementary food required for the conditions of introduction, the provision of aerodynamic qualities that allow you to feed the product over a long distance without any extra effort, and a shape that provides stability when the accessory is at the bottom of the reservoir with certain current forces.

Products in the form of a parallelepiped and a cylinder are considered classic forms, but products in the form of a pyramid, cone, spherical shapes and a ball are also used. The advantages of cylindrical types are the speed of filling the accessory with a mixture of any fraction and high aerodynamic properties, but such forms are unstable in currents and are subject to rolling, which often frightens cautious fish approaching the bait.

Rectangular types are more difficult to fill with bait, and their aerodynamics are much inferior to a cylinder, but they are much more stable on all types of soil and look more natural than other geometric shapes. The feeder method and similar products are natural in appearance, but due to their design features they do not allow delivering bulk mixtures to the fishing point.

Based on these considerations, we can confidently say that there is a variety of types of feeders, which allows you to cover any fishing conditions with one or another advantage in a certain current situation.

The fastening element, in the form of a winding ring with a swivel, is placed at the end of the workpiece opposite the bullet. Due to the center of gravity concentrated at a certain point, the bullet feeder for the feeder has a high degree of aerodynamic characteristics, which allows the tool to fly over particularly long distances, sometimes covering distances of more than a hundred meters.

The workpiece is fastened by making a wire hook, attached to the edge of the cork in a hole pierced with an awl or nail. The grooves inside the cork, made to screw it onto the neck of the bottle, act as ribs that hold the bait inside. A simple, miniature, but quite effective device is capable of attracting fish at short fishing distances in slightly flowing reservoirs, and will also help out in moments of lack of bait devices or their loss, saving fishing from failures.

To impart a positive buoyancy property, a foam boss is built into the upper part of the curler, balanced with the workpiece in such a way that the upper part of the tool is kept above the surface of the water, and the lower section with bait is in the water, luring fish. Instead of a boss, it is possible to use the method of foaming the volume, followed by polishing the surface of the workpiece with sandpaper and painting it in a noticeable color.

"Watermelon" or "pear"

Anglers who prefer to fish for carp use these feeders for still water. The equipment for this type of fishing is usually made sliding, with one to four hooks on leashes if desired. Such products are rarely used for boilie equipment, more often for puffies or polystyrene foam.

Watermelon design:

- the weight of the feeders ranges from 15 to 60 grams;

- metal ribs, located quite sparsely;

- There is a through tube inside.

The equipment is collected from one feeder; it is not recommended to pair them.

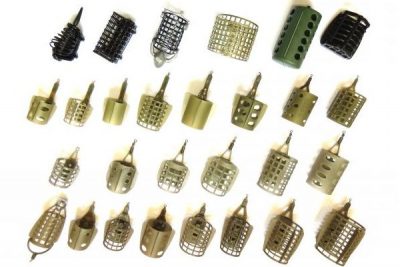

Types of feeders

Manufacturers of fishing products offer feeders various types of feeding troughs. It is important for an angler to understand under what conditions a particular model can be used.

Container feeders

Container feeders are the most popular type among feeders. These include:

- square cells;

- round;

- "bullets".

Square cages are a universal type of feeder, used in standing and flowing reservoirs. They are equipped with a flat weight soldered into the body. They do not have good aerodynamics and are more often used when fishing at short and medium distances. Some models are equipped with a plastic bottom, which prevents rapid erosion of the nutrient mixture.

Triangular-shaped containers are not widely used among feeders

Round cages - unlike square ones, have good flight characteristics and are used for long-distance fishing. When fishing in the current, it is recommended to use slightly flattened structures that better resist the flow of water.

Loaded

“Bullet” feeders have a round body made of thin wire. The weight is located at the bottom, which improves aerodynamics. They create a minimum of noise when splashing down, so they can be used for fishing in shallow water.

Bullet of different sizes

Long-range feeders for feeders

When fishing, situations often arise when an angler needs to cast a rig 70–100 m. For this, long-range types of feeders are used, which differ in:

- metal body;

- cargo located at the bottom;

- small volume.

The only drawback of long-range options is their slow ascent to the surface, which eliminates the possibility of fishing behind steep drop-offs and edges. To avoid snags when landing fish, the feeder has to get up from the chair and lift the rod up with outstretched arms.

For live bait

Feeder versions of feeders for delivering live components to the fishing zone differ from other models in the presence of a bottom plug that prevents worms and larvae from falling out during casting. Such designs are used in early spring or autumn, when a worm, bloodworm or maggot is used as bait.

Structures intended for live bait have a bottom.

After the container falls to the bottom, the living components are gradually washed out through the holes. The volume of such models rarely exceeds 50 ml. They are not suitable for vegetable bait mixtures.

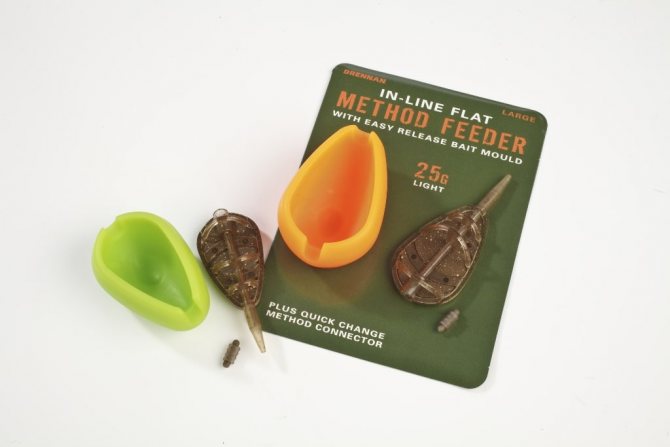

Flat method

Feeders for the flat method are used only in standing water. They have a “blind” mounting of the fastening, due to which the fish self-hook when biting. Food components are packed into a rigid rib structure. A hook on a leash 5–7 cm long is hidden in the bait.

Effective when fishing with plant-based baits.

Flat models are designed for fishing for carp, crucian carp and tench on reservoirs with a muddy bottom (crucian carp on a feeder). Thanks to the large surface area, the structure does not get stuck in muddy soil. Read how to make a flat with your own hands.

Floating feeder

Floating-type models have positive buoyancy and remain on the surface of the water after casting. When spilling out of the container, food components create a cloud of turbidity that attracts fish species that feed in the middle and upper layers of water:

- bleak;

- saberfish;

- roach;

- rudd;

- silver carp.

Floating options do not have their own load. The moistened mixture acts as a load. Due to their large volume and low weight, such structures cannot be thrown far. They are used for fishing 20–30 m from the shore.

Spring feeders

The feeder feeding element called “spring” consists of a hollow tube 5-8 cm long and a wire attached to it, twisted in the form of a spiral. Due to the sparse arrangement of hard ribs, food from this design is washed out very quickly, so they are used for fishing in standing waters.

The “spring” is not suitable for rivers with moderate and strong currents, since due to its rounded shape it does not adhere well to the ground.

The load is placed on a hollow plastic tube or attached to the lower spiral using a winding ring.

"Inline" feeders

“Inline” models are made in a sliding version and move freely along the cord or fishing line during fishing. This is the only design that is allowed to be used in competitions, since even if the monofilament breaks, the fish will be able to free themselves from the equipment and will not die.

Inline-type feeders are attached to a cord or fishing line via a swivel.

Inline feeders can have various modifications and differ in weight and shape. Feederists use them on flowing and standing reservoirs from early spring to late autumn.

Feeders for fishing in the current

Feeders for currents are made in a sliding version, which ensures clear registration of bites. They are distinguished by:

- square shape, which prevents the structure from rolling over the bottom soil under the pressure of a directed flow of water;

- frame made of thin wire, less susceptible to current;

- a heavy weight of a streamlined shape, soldered into a metal case.

When fishing on rivers with moderate currents, feeding containers weighing 40–70 g are used. For fishing on a fast river, models weighing from 70 to 120 g are used. To make the structure lie more securely on the ground, feeders use thin braided cords that are less susceptible to current pressure.

Coil spring

The most primitive and easy-to-make feeder, which is used only for ponds with standing water. The equipment can use either one or several feeders at once. Usually they are not shipped, so the final link is a sinker, which is tightly tied to the tackle.

The coil spring cannot be confused with other types due to the following characteristics:

- simple spiral shape;

- a through tube is usually installed inside;

- made from copper-clad wire or painted afterwards.

The “crucian carp killer” is considered a classic rig; it consists of three small feeders. A leash with a hook is tied over each of them; it is advisable to do this through a small outlet, then the hooks will not get tangled with the main fishing line.

There is a tackle consisting of two feeders, they call it the “carp killer”. For this type, the twisted spirals should be larger in size, leashes and hooks are placed in the same way as in the “crucian carp killer”, only their size should be larger.

Tackle with one feeder is used the least often; little bait will fit into such a tackle, and few people want to re-throw it often. The formation of equipment is carried out along one line:

- feeder;

- leash;

- hook.

Some fishermen place a sliding weight in front of the feeder, which is secured with beads or float stoppers. But more often they attach the sinker to a swivel, which will complete this simple tackle.

DIY spring feeder

Designs in the form of springs will require for their manufacture a set of plastic tubes, which are similar in appearance to the used ballpoint pen, and steel wire with diameters from 1.5 to 3 mm. The wire is wound in even turns onto a cylindrical surface, placing the turns tightly together.

Next, the body of the spring is formed from the wound coils according to the principle of symmetrically decreasing the diameter of the spiral from the center to the edges of the product. The shape of the workpiece should resemble contours similar to an egg. The formed body is threaded onto a plastic tube and secured with wire stoppers at both ends.

A hollow tube with a fixed spring is placed on the cord, ultimately forming a sliding mount. Leashes with hooks are attached to the coils of the spiral, and bait is tightly packed into the cavity of the spring. The spring, compressed before casting, weakens in the water, throwing out particles of bait and creating a cloudy spot around itself, and the remaining bait with hooks in the volume of the device will be sucked up by the fish that come up for the bait.

The operating principle of such a feeder is based on the dynamic properties of the main element - the spring. First, the fisherman squeezes it, secures it in this position with viscous bait (a mixture of millet, bread), and throws the tackle. In the reservoir, the bait gets wet, the spring sharply straightens, throwing the bait upward.

To assemble it you need materials:

- film container (preferably with a metal lid);

- spring (as in the picture);

- gel pen;

- a piece of lead;

- matches;

- drill.

We insert the spring into the film case, fill the bottom with lead so that the spring does not come off when casting. It should compress and unclench freely. We make a hole in the center of the case and insert a rod there and melt it.

We clean the rod cavity with wire. Make a hole in the bottom of the case. Insert the piston, melt the other end of the tube. When the spring is level with the edges of the case, the rod should be slightly peeking out. Pressing down the spring, drill two more 7 mm holes on the sides of the case. The structure is ready.