Accessories for creating a trailer

To create a boat trailer you will need a considerable amount of different materials.

To begin with, we note that it is advisable to purchase a certified torsion axle and coupling device from a specialized store. You will also need the following materials and parts:

- profile with a wall thickness of 4 mm and dimensions 60x40 (as an alternative, you can use a pipe with dimensions 80x40x3.5);

- channel 12;

- metal sheet (thickness 2 mm);

- wings;

- support leg;

- wiring;

- lighting elements;

- wheels;

- winch;

- keel blocks (can be made independently)

- anti-corrosion coating and paint of your choice.

You should not buy too thick channels or heavy pipes, otherwise the weight of the future trailer will subsequently increase significantly.

In turn, the latter will increase the load on the car engine and gearbox. In addition, fuel consumption will noticeably increase. For these reasons, select high-quality lightweight materials, but, of course, high strength.

When making a boat trailer, special attention should be paid to the dimensions of the product, that is, dimensions and weight. In addition, do not forget to re-inquire about the capabilities of the vehicle to which this boat trailer will be attached in the future.

The total weight of the towed trailer and boat must not exceed the maximum permissible values specified in the vehicle registration certificate.

Advantages of a DIY boat trailer

Despite the fairly large selection that has formed on the boat trailer market, many decide to create a similar design with their own hands.

This is primarily due to the following advantages:

- Costs are significantly reduced.

- At the time of operation, you can carry out repairs on your own.

- You can get a design that will meet established standards.

However, there are several significant disadvantages, which are primarily associated with reduced reliability. If mistakes are made, the created trailer will not be able to serve for a long period.

When creating a homemade design, you should take into account all the recommendations that eliminate the possibility of making a serious mistake.

Registration

Pajero mini

In order for the trailer to be registered, you need to obtain a conclusion from an organization that has a license to test and test vehicles (some driving schools, MREO, sometimes even private organizations with a license). To conduct the test, the organization that will be engaged in this good cause must provide drawings of the trailer, which must be completed properly (a high-quality drawing indicating all dimensions and parameters).

If the drawing is not made professionally, you should not even try to register. They will refuse you even when submitting documents, you will just waste your time.

If everything is fine with the original drawings and the vehicle passes the safety test, then it will be assigned a registration number and given a maintenance (technical inspection) coupon, which you must have with you every time you use the trailer (stick it on the windshield of the car so that the traffic police can clearly see even from behind the bushes).

Trailer registration

A device for transporting a boat requires registration with the traffic police. Therefore, after purchasing a trailer, it must be registered within 10 days from the date of purchase.

To register you will need:

- Collect a package of documents, which consists of:

- a document confirming your identity;

- vehicle passport, which is issued upon purchase;

- purchase and sale agreement.

- Contact any traffic police department, regardless of your place of registration or residence, and fill out an application for trailer registration in accordance with the sample.

- Pay the state fee, the amount of which can range from 350-1500 rubles depending on the type of registration actions.

- Provide the purchased device for inspection to a traffic police inspector, who will check the VIN numbers and put the appropriate mark on the completion of the procedure.

- Submit documents for registration.

Upon completion of registration, you will receive a certificate of registration, as well as a state registration mark. A registration note will be made in the vehicle's passport.

We suggest you read: How to make a floating float

Once every two years for trailers that are less than 5 years old, and once a year - if longer, the trailer must be inspected. The date of each inspection is indicated in the coupon for the device.

For owners of categories “B”, “C” and “D”, the use of light trailers with a weight not exceeding the weight of the loaded vehicle is allowed, and the total sum of the vehicle and trailer must be less than 3500 kg. For heavier installations you will need to open category “E”.

Main assembly steps

How to make a motorhome on wheels yourself, photos of finished work

The future design must accommodate the watercraft so that its mass is distributed evenly relative to the longitudinal axis. The load distribution relative to the transverse axis is designed in such a way that the front part accounts for 65-75% of the boat's weight.

Frame assembly. It is recommended that assembly be carried out not with bot connections, but with the help of a welding machine. Spars and cross members are mounted separately from the chassis. Perpendicular elements can be strengthened with a triangular gusset, which is cut from sheet metal. The beam is attached to the frame with bolts. If there are springs, studs are welded under the eyes. It is necessary to maintain strict perpendicularity to the axis of the bridge relative to the axis of the frame. It is advisable to purchase the fastening mechanism ready-made, since it will bear a high load. It is attached to the drawbar by welding or bolting.

Geometry check. An important point is to check the perpendicularity of the bridge or beam with respect to the axis of symmetry. This check is carried out visually. Having hooked the trailer to the car, you should drive a short distance in a straight line. If the geometry is broken, the trailer will pull to the side. Load distribution is determined with a dynamometer. While the trailer is not equipped with fastening elements, the boat should be moved forward and backward until a force of 500-800 N is applied to the towbar. Having aligned the boat, you can apply the appropriate marks.

Equipment installation. A support leg or steering wheel is an optional part of a trailer, but a very useful one. After coupling, the wheel should rise and be locked in this position. The wheel is lowered only when it is necessary to roll the uncoupled trailer.

Metal fenders are welded, and plastic fenders are attached to the frame with pre-prepared brackets. Some craftsmen screw the winch to a simulated front side, but since most devices do not have sides, the mechanism is welded to the drawbar approximately above the steering wheel.

Conical keel blocks are installed on a horizontal axis. If regular rollers are available, they are mounted on inclined axles. The angle of inclination is equal to the angle of the plane of the boat side

It is important that the boat rests on the keel blocks, but does not hang on them, otherwise the bottom can be damaged

There is another option for placing a flat-bottomed boat (suitable for inflatable models). A slipway with supports is mounted on the trolley platform. The cradle slats should be wrapped with foam rubber or carpet so that accidental friction does not damage the material of the boat. If there are supports, keel blocks are not needed, but rollers or wheels should be installed at the rear of the trailer on which the boat will roll when loading or unloading. This is the modification of a boat trailer for launching a boat.

Design improvement. The main work can be considered completed. The modification is aimed at improving the aesthetic appearance and increasing functionality. First of all, all metal structures are coated with a primer. If there are uneven areas, you can apply putty and then paint. Mud flaps improve the appearance, but do not forget that their presence is a requirement of the traffic police. For electrical wiring, you will have to purchase a standard socket connector, which is attached to the car's towbar.

Make sure that the boat does not damage the wires when loading or unloading. For this purpose, they are pulled from the bottom of the frame and attached to the supporting profile.

Careful manufacturing and operation of the trailer will allow you to get excellent results. In terms of reliability, such a device will not be inferior to the factory one, and in some respects it may even surpass it.

An important component of long-term service is also proper storage of the trailer. If possible, it should be treated with an anti-corrosion compound.

Dimensions

How to make, install and remove secrets on car wheels yourself

First of all, you need to decide on the dimensions of the trailer body. This must be done before planning the entire structure, as there are strict standards provided for by law.

Before carrying out all the work, you need to measure the boat itself (height of the sides, length and width at the narrowest and widest points), because the dimensions of the trailer are “adjusted” to it. For owners of larger boats, it is also necessary to measure the length of the tow vehicle from the front bumper to the end of the mounting mechanism on the rear.

Dimensions of the trailer for transporting floating equipment:

- The height of the entire trailer, including the boat and on wheels, should not be more than 3.8 m, so as not to block the view of the owner and drivers on the road from behind;

- Width (with a boat) no more than 2.2 m, so as not to block the view and for a normal position on a standard road lane;

- The length of the trailer together with the boat and vehicle (tractor) is a maximum of 20 m; more than 20 m is not even a road train - for reasons of road safety.

Advantages of using a trailer

Using a trailer for transportation has a number of advantages:

- The device has special fasteners , keel rollers, lodgements and side rollers that allow you to securely fix the structure.

- The device is able to easily transport heavy loads on uneven roads with holes and potholes due to its spring design.

- A large assortment with different configurations and lengths , allowing you to choose the most optimal option for transporting your watercraft.

- The ground clearance is exactly the same as that of a passenger car.

- Allows you to transport the boat in inflated form , which significantly saves time, without requiring it to be assembled and disassembled.

How to connect a trailer to a car

You will need to purchase a trailer hitch

When assembling the coupling part, pay attention to the length. The shorter it is, the easier it is to control the trailer.

The easiest way is to make the coupling part from 1.5 to 2.5 m long.

Do not make the coupling part short, because the trailer will react even to a slight turn of the wheels, this will cause the load to fall.

Make the towbar from a square pipe. Take a welding machine and weld three pipes. Place the middle of the connection point along the tow axle. Weld a metal corner to the assembly, so the structure will become even more reliable.

Then proceed to install the safety rope. If you don't have one, use a chain instead. Select the length so that the chain does not touch the road when driving.

Install the connection coupling; use bolts or welding for fastening. Welding is considered a reliable method of fastening.

Are you going to do the fastening with bolts? Install no more than two. If you do more, drilling holes in the mounting points will weaken the frame.

What can be altered in a trailer without certificates and permits?

Any handy man himself or with the help of a neighbor (brother, matchmaker, friend) is capable of making anything out of anything. Therefore, you need to understand that the question is posed somewhat differently - will there be any problems with the traffic police due to the modification of the trailer?

On this matter, the traffic rules say quite transparently - any change is allowed that does not affect the main structure and does not affect the original characteristics. Therefore, you can quite calmly proceed to such alterations as:

- Coating the trailer elements with anti-corrosion and anti-gravel coating and painting the body (possibly in a different color if the base color is not specified in the title)

- Minor expansion of the side, installation of a frame for the awning or installation of a plexiglass cover, additional internal lining of the bottom and sides

- Replacing wheels, tires, fenders, sides or awnings with new ones, including those slightly different from the factory ones

- Installation of mounts for spare wheel, tool box, washbasin, etc.

- Replacement of lighting equipment (if the basic design does not change, but only the quality and appearance)

You can change the shape of the sides, but so as not to go beyond the basic parameters. But more radical alterations are another story.

Stages of making a boat trailer with your own hands

First of all, you should calculate the balancing of the trailer so that the weight of the boat is distributed evenly along the sides (across the width of the boat). Well, most of the load (along the boat) should fall on the front side 65-75% (from the side attached to the car - to the tow bar).

Creating a Frame

- To create a durable structure, you must use only a welding machine. All frame elements (profile or pipe) are welded together with seams separately from the chassis and axle (grabbing and strengthening with a plate is unacceptable) and are reinforced with a “kerchief” made of thin metal.

- Attach the axle to the frame with M12-13 bolts, strictly perpendicular to the central beam (wheels). Then you need to put the wheels on the trailer, drill holes at the junction of the axle and the towbar and attach the fastening mechanism (it is advisable to buy one ready for trailers).

Frame check

- After this, it is advisable to check the finished body for perpendicularity of the axis in relation to the wheels. To do this, you need to couple the trailer to the car and drive it a little along the road to see if it leads to the side.

- The next step is to check the balance of the frame. We install the boat on the trailer and see what load is placed on the tow bar. The load on the coupling mechanism should be 50-80 kg. If the frame “leads” or the balance of the body is not maintained, remove the axle and set it to its normal position.

Frame equipment

- Next, we install the support leg on the body; it is also called the steering wheel. A very convenient thing when moving the trailer manually (but not necessary). It has a lower handle, with which you can adjust its height, and a lower handle, with which you can adjust the position of the wheel relative to the trailer axis.

- Before driving onto the highway, the wheel is raised up and fixed there with a handle. If it is necessary to move the trailer manually, it is lowered and used as a third wheel, with the ability to turn in different directions. Then we install the metal wings by welding. If the wings are plastic, then we make fastenings and install them with bolts.

- After this, we weld the winch support to the front of the axle (approximately above the support leg). It is made from a piece of pipe 60x40x2 - fastenings for wings and keel blocks are made from the same pipe.

Keel blocks are attached to the frame with pieces of metal no less than 4 mm. thick.

- You should also take into account when installing the rollers that they should rotate very easily on the keel block, so that when dragging the boat onto the trailer they do not break and damage the boat (if it gets stuck and does not spin).

- The dimensions and angle of the keel block support should be such that the rollers do not put too much pressure on one side, but are completely adjacent to the skin of the boat. This way they will deform the bottom of the boat less. In order to install them correctly, you need to make a model of the keel of your boat from a piece of plywood and align the wheels on it.

- If you need wheels of non-standard sizes, you can easily make them yourself. Rollers for the keel block are made from polyurethane, but for this you will need a lathe. Grind the polyurethane on a machine to the desired size, drill a hole and install it on a stud or bolt as an axis. Then we weld a U-shaped mount for the axle from the corner and twist the finished roller together.

Finalization

- After all the components of the trailer are in place, the trailer still needs to be finished. We prime the metal parts; if desired, we putty and paint the rough places.

- After this, we install mudguards and wiring with side lighting.

- We connect this whole thing as on a regular trailer using connectors at the towbar and fix the wiring on the body under the boat so that it does not get damaged.

A self-made trailer can serve faithfully for many years if it is properly cared for. When you are in a car on the road with a trailer attached, then behave appropriately, carefully and in accordance with all the rules.

It should also be mentioned that experienced boat owners store their boats directly on the trailer in winter. This does not harm the trailer, and the boat is preserved much better in this position.

PVC boat trailer

https://myownship.ru

DIY PVC boat trailer

There are simply a huge number of different designs on sale that can be used not only for transporting boats, but also many other cargoes.

Before starting work you should:

- Decide on the most suitable sizes.

- Select the required materials and tools.

- Design the chassis taking into account established standards and other points.

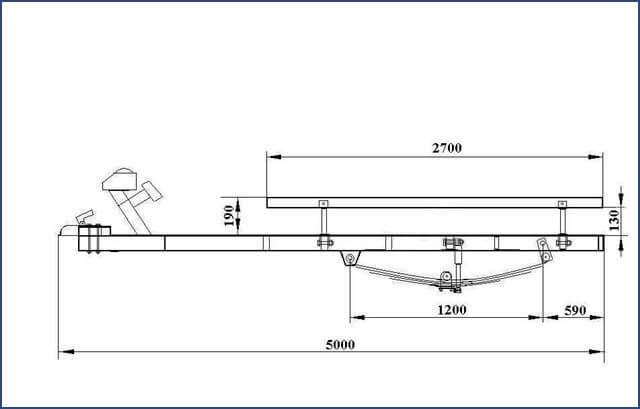

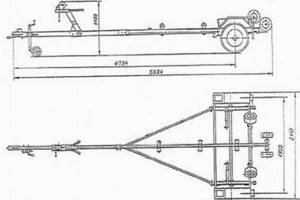

Boat trailer drawing

Trailer sizing

At the design stage, you can use ready-made drawings or carry out independent development of the project. Do not forget that there are strict rules provided for by law.

At the time of design, measurements are taken from the boat:

- Length of the entire structure.

- Side height.

- The length and width of the narrowest as well as the widest parts.

Established norms at the legislative level determine that the structure being created must have the following dimensions:

- Length no more than 20 meters.

- Width no more than 2.2 meters.

- Height no more than 3.8 meters.

Required materials and tools

You can create a boat trailer with your own hands; this requires certain materials and tools.

The collection of a classic design can be carried out if you have:

- Sheet metal, the recommended thickness of which is 2 mm.

- Metal pipe used to assemble the frame.

- Channel, the thickness of which is 12 mm.

- Metal profile with a wall thickness of about 4-5 mm. Recently, to significantly lighten the structure, they began to use aluminum profiles, which are more expensive, but can last much longer.

- You will need plastic used in the manufacture of mudguards and facing elements. This material is characterized by increased resistance to environmental influences, as well as low weight.

- Wires for connecting electricity. Do not forget that in the rear part of the structure there should be lighting fixtures and signs to indicate the trailer.

- Car lights with direction indicator.

- Manual winch and cable to improve the reliability of connecting the trailer to the vehicle.

- Support leg with lifting mechanism.

- Primer and paint to protect the main elements from exposure to high humidity.

After finding everything you need, you can begin the actual work. The recommended set of tools is as follows:

- Hammer.

- Measuring instruments with marker.

- Electrodes and the most suitable welding machine.

- A set of keys.

- Drill and drill bit.

- Grinder for working with metal.

Chassis

Do not forget that there are quite a large number of rules regarding the creation of a chassis. By complying with them, you can ensure the required safety at the time of movement.

Among the main points we note the following:

- The axle intended for mounting the wheels must have increased strength.

- Wheels are used in versions that are installed on motorcycles or cars.

- When creating the chassis, the fact is taken into account that the front part of the structure, as a rule, accounts for about 70%, the rest of the load is distributed evenly. Due to this, the maneuverability of the structure is significantly increased.

Manufacturing instructions

In order to avoid mistakes at the time of work, you should initially develop a project, which is represented by a combination of drawings and basic technical information.

The entire direct installation process can be divided into several stages:

- First, the frame is assembled, the individual elements are connected using welding, due to which the required strength is achieved.

- The axle, which is required to install the wheels, is attached to the frame using a bolt connection. This is done in order to eliminate the possibility of loss of strength due to vibration load.

- The fastening element is installed in the area where the axle and towbar connect. Craftsmen recommend using exclusively ready-made structures, as they provide the required level of connection reliability.

- The next step is to install the wheels. This kind of work is quite simple to do.

After the work is completed, you should test drive the trailer, as there is a possibility that balancing will be required. In order to eliminate the possibility of the boat capsizing during its transportation, supports are also installed.

Retainers can be created using a special pipe. The final stage consists of cleaning the surface, applying primer and paint, which significantly extends the service life of the product.

Materials for assembly that we need

There are quite a lot of components, because the project is quite complex from the technical side. First of all, you will need parts that are manufactured industrially, and it is almost impossible to make them separately - a torsion axle and a coupling device.

In addition to the previous components, you will also need a dozen different parts that you can easily make yourself. They can be listed as follows: support leg and wings, lighting equipment, wiring, winch and fasteners, wheels, keel blocks, rolled metal and paints.

Yes, to make a trailer for transporting a boat, you will need all this together, without exception.

The total cost of materials will be ten to fifteen thousand, if you are not particularly picky in your purchases. Making something yourself will reduce the price. The most expensive parts are the torsion axle, wheels and winch.

Trailer parameters and registration with the traffic police

Most often, in villages the river (or lake) is just a stone's throw away and there have never been traffic police posts on the road to the reservoir. Nobody wants to buy an expensive factory trailer to transport a boat 200-300 meters or even a couple of kilometers, so they make trailers for floating craft from scrap materials.

Such “devices” very often in small settlements are not even registered (although it is necessary), since there is no highway, and along the dirt road “gardens” 500 meters you can go fishing.

In big cities, registration of this vehicle is simply mandatory - you simply cannot get to the reservoir without it, the “valiant, honest and dear to your heart” traffic police will stop you at the first checkpoint and they will “slap” a fine or confiscate the trailer.

Lastly about trailers

Since we are talking about an inflatable boat, you should not use trailers with rigid suspension when transporting it. Choose softer options.

With high suspension rigidity, the trailer will jump on every pothole and hole, and along with it your PVC watercraft. Nothing good will come from this to anyone present.

That's all. Upgrading a flatbed trailer is truly a worthwhile alternative to purchasing a separate boat vehicle. Do you agree?

Write your opinion in the comments, subscribe to our website, invite your friends to discuss!

(

6 ratings, average: 4.33 out of 5)

Did you like the article?

Subscribe to updates and receive articles by email!

We guarantee: no spam, only new articles once a week!

How to convert a regular trailer

Now let’s look at the conversion (upgrading) of a conventional trailer into a cart for a boat.

If you don’t want to waste money and time, you can save all this significantly. You can convert your regular car trailer to accommodate boats. This is quite easy to do. You will need all the same tools as in the previous instructions.

We install a regular trailer in a convenient place and begin to disassemble the body. You can throw away the body or give it to someone - you will no longer need it. By standards, the drawbar of the design is not very long. To avoid the bow of a boat or boat hitting your car while moving, you will need to extend it by about 1 meter (do not forget to provide for the possibility of assembling and disassembling it).

The next step is to install a stop under the leg. Take the same profile pipe as in the previous step. Buy rivets and rivet the rubber. According to reviews from people who have redesigned their trailer in this way, this idea is very successful.

To prevent the legs from tossing during transportation, use regular strapping tape. Secure it with bolts or rivets directly to the beams of the structure. This way you will get a convenient, and most importantly, durable fastener.

Now make or buy ready-made rollers. They should be installed and secured so that they can easily move around the frame. In order to find the exact location for them, you can use the layout. As already mentioned, the layout can be cut out of fiberboard or chipboard, and using it to find the desired angles and locations.

Don't forget to equip your cart with additional lights so as not to break the law. Some people use old UAZ headlights for this. If your trailer already had good wiring, just stretch it to the new lamps, and if the wiring also had to be replaced, it is better to take a longer wire than you need, because the excess length can always be removed using clamps under the trailer body.

If the previous wiring was good and you don't want to change it, you can buy a regular piece of wire and solder it to the old one. It is not recommended to use the twisting method - in this situation it will not be very reliable.

If you want to convert your main trailer into a boat dolly, treat it accordingly. After all the treatments and upgrades, you will no longer be able to use your trailer for everyday purposes. Take careful measurements of the boat and all components when purchasing.

To learn how to make a PVC boat trailer with your own hands, see the following video.

Transportation options

Nowadays, the conversion of trailers Enot, Krepysh, MZSA and a number of other popular models from trusted manufacturers is widely popular among car owners.

There are many ways to adapt a flatbed trailer to a boat trailer. But they are all conditionally divided into 2 categories:

- using a slipway;

- without a slipway.

Motorists living in St. Petersburg, Perm, Khabarovsk, Shakhty or somewhere near good fishing reservoirs do not always want to fish from the shore. You know that fish hide in the most secluded corners. You have to reach them. And for this you need a boat.

Not everyone can afford a boat trailer. But making your on-board vehicle a universal vehicle is a feasible and inexpensive task. If you want to launch and transport a PVC boat on an onboard trailer, choose the option for upgrading it that suits you.

In its pure form, a flatbed trailer has several problems:

- sharp edges on the flaps;

- protruding fasteners (bolts, nuts, screws);

- sharp corners;

- insufficient width of the inner sides (not every boat will fit between them);

- friction of PVC on the bottom and sides provokes abrasion and wear of the material.

That is, a standard car flatbed trailer will not be suitable for transporting a PVC boat. Something needs to be done.

Let's consider several options for upgrading the on-board vehicle, which will allow you to make an excellent universal trailer for almost a few hundred rubles.

- Carpet or linoleum. The point is to purchase similar material, covering the most dangerous areas of the trailer with it. You can completely cover all the metal elements of the trailer with it. This will allow the boat to be transported upside down or keel down. Only on the condition that the outboard motor is uncoupled from the boat;

- Slings with tightening. They are needed to securely secure the watercraft that you load onto the boat. After all, if you simply load it on board, at the first turn and acceleration to normal speed, the lightweight PVC product will simply fly away. It does not carry 330-360 kg, like some wooden or metal boats. That's why slings are needed. They are quite cheap. If you are converting a trailer for a three-meter boat, use 3 trails to have some reserve. Distribute them evenly along the length of the craft. The third sling is used during long-term transportation to prevent longitudinal movements. Therefore, it is laid along the keel line from bow to stern;

- Motor mounts. They will come in handy if you transport the boat with the keel up (in an inverted position) and the engine is located under it. Here you can simply install several metal ears on the floor through which the belts are threaded and the engine is fixed. Or create a separate box for the size of the motor.

Roughly speaking, several elements for fastenings and covering with soft material will allow you to turn an ordinary flatbed trailer into a vehicle with universal capabilities without registration. These are not major design changes that would get you fined. Therefore, there is nothing to fear when meeting with traffic police inspectors.

Use of a slipway

Personally, I believe that using a slipway with lodgements is the most suitable, simple and affordable option for upgrading a flatbed trailer into a vehicle that allows you to transport PVC boats.

A slipway with lodgements is a fairly simple design that, if desired, can be made with your own hands.

The principle of using the slipway is that it is installed on a regular flatbed trailer. The fastening is simple, but at the same time quite reliable. This allows you to get a multifunctional collapsible trailer.

By attaching the slip liner to the trailer, you get a full-fledged boat trailer from a regular trailer. This insert is used for:

- PVC boats;

- jet skis;

- keelboats, etc.

Yes, if you have such a device, you will not be able to transport the PVC watercraft upside down. But that's not scary. Since the slipway is mounted on the sides, the space under the boat remains completely free.

Don't forget about additional fastenings and straps that hold the boat firmly on the slipway with supports.

Reinforced trailer for cars

Section: Plumbing

The trailer is single-axle (two-wheeled), has a classic layout and a very simple design. In addition, the materials used to build the trailer are those that a craftsman always has in stock.

The frame of the trailer is combined with the frame grille of the body (it turns out to be a load-bearing body: one can distinguish one from the other rather conditionally). The frame is formed by two side members and a pair of cross members (front and rear cross members). Five more crossbars located between the traverses can be structurally attributed to the platform lattice. The cross members and cross members have small cantilevered outlets relative to the side members. Longitudinal elements are welded to the ends of these outlets on both sides, which simultaneously serve as the lower trims of the side frames: four posts are installed and welded onto the elements (just across one cross member), and the upper trims are attached to them.

The spars are made of rectangular pipes 60×30 mm. All the other frame and body frame parts listed above (traverses, cross members, racks, trim) are made of square steel pipe with a cross-section of 25x25 mm.

The front and rear sides of the body are the same. They are made folding (this allows you to transport long loads on a trailer), and therefore their frames, although all made from the same 25x25 mm square pipe, are made separately from the general body frame. The platform grille on top is covered with a 2-mm duralumin sheet, forming the floor of the body, and the outside sides are sheathed with thick tin - 0.8-mm steel sheet. The floor is attached to the grille with M5 bolts with countersunk heads, and the side trim is carefully (dotted) welded to the frames and posts.

The bridge beam also has a tubular rectangular cross-section: it is welded from two identical sections of channels No. 5, inserted into one another. Two wheel axles are pre-welded at the ends of one of them. The gaps between them and the beam channels at the ends were closed with plates made of steel sheet.

The beam is connected to the frame side members by means of two springs used from the old Moskvich-412 car; 13-inch wheels were also taken from the same car. The middles of the springs are pulled to the beam by stepladders, and their ends are attached to the side members: one is put on the axis of the bracket, and the other is put on the axis of the shackle. I considered shock absorbers in the design of a simplified cargo trailer unnecessary.

With such a suspension, the distance from the ground to the platform was about 600 mm, which, as operation has shown, is quite acceptable.

The trailer drawbar is double-beam. Made from the same rectangular pipe with a cross section of 60×30 mm as the side members. The rear ends of the drawbar beams are docked and welded to the front ends of the side members with a 200 mm overlap. The front ends of the beams converge on the body of the towbar and are also welded to it. I have it homemade, but I never go on public roads with my trailer (and there is no need for this). Technical requirements simply prohibit the use of homemade towing devices.

The trailer doesn’t have brakes—I use the tractor’s brakes to stop or slow down the speed. But I installed alarm devices—tail lights with turn signals and brake lights—so that my actions would always be clear to those driving on the road.

V. KURAKIN.

Schemes and drawings of a homemade trailer

What to consider when choosing

When choosing a device for transporting a PVC boat, you should focus on models from manufacturers with a good proven reputation. In addition, do not forget about the power and functionality of your own car.

Criteria for choosing a trailer:

- The frame is a load-bearing part, so it must bear a large load. Please ensure that the base metal of the structure is not too thin, since due to constant shaking, all fasteners will become loose and eventually come out completely. The device must have an anti-corrosion coating (galvanized or painted).

- Wheels. It is preferable to use equal wheels, both on the car itself and on the trailer, then there will be no problems on the road. If there are no identical wheels, then use tires without tubes for the design.

- An autonomous braking system is a must for devices weighing over 750 kg.

- Elements of light signaling. The trailer must be equipped with brake lights, a license plate light, and turn signals.

- A winch is a special device that allows you to pull a boat out of the water and load it. Carefully inspect the bow stop attached to the tongue. When welding seams are very noticeable, there can be no question of quality. Check the mechanism and make sure that the cable and belts do not rub against nearby elements or PVC. With a manual mechanism, the handle must have free play.

The trailer may include an awning, but its presence is not necessary. When choosing, you should consider the following recommendations:

- Consider how much load the trailer can handle. Each of them is designed for its own dimensions.

- Additional components. The presence of a cradle, keel rollers and rollers allows you to transport cargo safely. If they are absent, you will need to periodically stop and check the securing of the load.

- The ground clearance must be no less than that of a car. It is preferable to have a folding stand, which ensures the stability of the structure.

- Integrity of light signals. Signals may be damaged during transportation, so check their functionality.

- Spring suspension. Regardless of whether a wheeled or lever beam is used, it is advisable to choose a spring suspension. An alternative is a dependent spring design.

- Take a good look at all moving parts and their connections.

- It is convenient to use models with a long cradle covered with soft fabrics.

Everyone chooses the model and company themselves, depending on the preferences and dimensions of the boat.

- The frame is a load-bearing part, so it must bear a large load. Please ensure that the base metal of the structure is not too thin, since due to constant shaking, all fasteners will become loose and eventually come out completely. The device must have an anti-corrosion coating (galvanized or painted).

- Wheels. It is preferable to use equal wheels, both on the car itself and on the trailer, then there will be no problems on the road. If there are no identical wheels, then use tires without tubes for the design.

- An autonomous braking system is a must for devices weighing over 750 kg.

- Elements of light signaling. The trailer must be equipped with brake lights, a license plate light, and turn signals.

- A winch is a special device that allows you to pull a boat out of the water and load it. Carefully inspect the bow stop attached to the tongue. When welding seams are very noticeable, there can be no question of quality. Check the mechanism and make sure that the cable and belts do not rub against nearby elements or PVC. With a manual mechanism, the handle must have free play.

We invite you to familiarize yourself with: Equipment for a winter donkey for burbot

How to make a trailer for a light car

Another option for a universal homemade trailer

- Determine the desired dimensions of the trailer and make a drawing, this will help you during assembly. It’s very good if you have stocks of old parts in your garage; they will be needed in your work. For example, take the connecting elements of the sides from the tractor, and knock down the sides themselves from the lining. Make the frame from a steel pipe; just buy a product with a diameter of 40 mm. Adapt a pipe of slightly smaller diameter for the draft. Buy three pieces, two you will use for longitudinal rods, and one for transverse rods. Don't forget to purchase a pipe for the bridge beam.

- Install tubeless wheels; shock absorbers from the old Ural will come in handy. In the store you need to buy a device designed to grip the tow bar and a safety chain.

What to pay attention to

You need to start by assembling the frame. You probably hope that your homemade trailer will serve you for a long time. Remember that service life directly depends on the strength of the frame. An important factor is rigidity. To assemble the structure, use welding, this guarantees a reliable connection.

Once you specify the dimensions of the trailer, try to assemble the frame. Lay out the elements on a flat floor, assemble the structure, fastening it with temporary clamps

Pay attention to the components of the frame, place them perpendicularly. Take a tape measure and measure the diagonals

The values must be the same, the discrepancy should not exceed 3%. If the discrepancy is greater, then it is worth reassembling the frame.

Since a rectangle is not the most reliable structure, reinforce the trailer with an additional stiffening rib.

Preparation of materials and tools

Proper organization of work will reduce the process to several hours. If any element is missing, the assembly is delayed, and this is an elementary law. This is why it is recommended to prepare material in advance. There is no point in giving an example of drawings, since there are enough of them on various forums dedicated to the manufacture of trailers.

On the other hand, each master must take the parameters of his boat as a basis, therefore, the dimensions can be different. If you have no experience, then it is better to use a ready-made drawing of a trailer that is suitable in size.

The general list may also differ, but the following materials will be required:

- Metallic profile. You can use a pipe instead. The wall thickness must be at least 4 mm, since the frame will be made from these materials.

- Aluminum profile. It is suitable for transporting an inflatable rubber or PVC boat. Aluminum will reduce the weight of the entire structure, however, when transporting heavy boats, you should take a closer look at the metal profile.

- The sides or bottom, if desired, are made of metal sheet 2 mm thick.

- At the request of the traffic police, the trailer must be equipped with fenders and mudguards. Here you can use sheets of polypropylene, plastic, or use ready-made products from other trailers and motorized strollers.

- Connecting wires and lights (marker lights and turn signals). You can use the tail lights of any car.

- It is advisable to buy a ready-made winch, since this mechanism must be reliable, so experimenting with it is not recommended.

- Beam with wheels.

- Primer, paint and anti-corrosion coating.

- Keel blocks.

The materials were chosen almost arbitrarily. The main thing is that they are durable and light. A heavy trailer causes increased fuel consumption, stress on the transmission, engine and wheels. One cannot ignore the capabilities of the tractor. The dimensions must correspond to the openings of entrance gates, garage doors and other structures near the storage location. The list of materials did not include a support that allows the trailer to be transported without a tractor.

Stages of making a boat trailer with your own hands

In this section we will tell you how to make a boat trailer with your own hands from the above components.

1. In order to be able to competently make a trailer for a boat with your own hands, you must be guided by the dimensions of your watercraft. Violation of the same indicators can lead to damage not only to the trailer, but also to the boat itself.

Also, do not forget about the capabilities of the vehicle with which you will be transporting; pay attention to such characteristics as the weight limit of the towed vehicle. Below is a drawing that is designed to transport boats up to 4.5 m long and weighing from 100 kg

To make the trailer exactly fit your boat, you can slightly change the dimensions.

3. Next, hang the support leg and safety rope on the trailer.

4. Then, from a pipe measuring 60x40x2, you need to weld a support for the winch and install it.

5. The wing supports are made from a pipe of the same dimensions as for the winch support.

6. And again using the same pipe, keel block supports are made. To support the keel rollers, metal of at least 4 mm in size must be cut on a guillotine and welded. In this case, the roller on the axle should move very easily, otherwise, if it jams, the keel of the boat will easily cut the roller to an unusable state. In addition, we note that the length of the keel block supports must be selected so that the wheels fall on the element of the longitudinal set, in this case the bottom will sag less. The angle of the wheels can be calculated using the bottom profile, cutting it out of plywood.

7. The penultimate touch of making a trailer with your own hands will be painting it. To do this, you must first coat the device with an anti-corrosion coating, and ordinary enamel can be used as paint.

8. The last stage of trailer manufacturing is to install lighting equipment and an illuminated plate for the license plate. To do this, you need to weld a beam from a light pipe and place everything on it.

So, the trailer is painted and ready for registration.

Finally, we note that with proper use, a trailer made by yourself will serve you faithfully for many years. But when operating a trailer, you will also need specific driving skills. When transporting a boat, always remember that you have a trailer behind you, and therefore you need to behave accordingly on the road. There are many different external factors that increase the width and length of the “corridor” occupied on the road by a car with a trailer, especially since the trailer with the boat located on it is much wider than the car itself. Overtaking when driving with a trailer is a rather dangerous maneuver, since the driver of the overtaken vehicle may not expect the trailer to appear and, as a result, may not have time to slow down in time. Always stay alert when driving a vehicle with a boat trailer, especially if the road is unfamiliar.

Safety on the road comes first!

Types of trailers

There are several types of trailers:

- The presence of a braking system makes movement safe and smooth.

Single-axle – used for transporting watercraft weighing about 1.5 tons and length about 6 m. Models of this type are equipped with coupling elements, marker and brake lights, connected to the vehicle’s electrical network . - Biaxial - larger structures capable of carrying a weight of about 2.5 tons with a size of up to 8.5 m. Due to two axes, the movement of the structure becomes uniform and, most importantly, smooth.

- Three-axle – used for transporting large boats with a length of up to 9 m and a weight of up to 3 tons. The design is very stable and can move smoothly even at high speed.

- Brake - equipped with a brake roll, winches and transportable wheel travel. The structure weighs over 750 kg. The presence of a braking system makes movement safe and smooth. The wheel travel helps distribute the center of gravity evenly throughout the structure.

- Brakeless - small-sized structures with a weight of less than 750 kg and a length of about 3-5.5 m. The suspension can be spring or rubber-band.

- The presence of a braking system makes movement safe and smooth.

Single-axle – used for transporting watercraft weighing about 1.5 tons and length about 6 m. Models of this type are equipped with coupling elements, marker and brake lights, connected to the vehicle’s electrical network . - Biaxial - larger structures capable of carrying a weight of about 2.5 tons with a size of up to 8.5 m. Due to two axes, the movement of the structure becomes uniform and, most importantly, smooth.

- Three-axle – used for transporting large boats with a length of up to 9 m and a weight of up to 3 tons. The design is very stable and can move smoothly even at high speed.

- Brake - equipped with a brake roll, winches and transportable wheel travel. The structure weighs over 750 kg. The presence of a braking system makes movement safe and smooth. The wheel travel helps distribute the center of gravity evenly throughout the structure.

- Brakeless - small-sized structures with a weight of less than 750 kg and a length of about 3-5.5 m. The suspension can be spring or rubber-band.

We suggest you familiarize yourself with: Aluminum boats Tunnel for a water cannon on an aluminum boat

Assembly process and key features

80x40x3.5 mm pipes can be used as the main frame. If it is possible to work with thicker material, this is not a problem, but lower density can lead to breakdowns, since boats weigh a lot.

Two pipes of eight meters each will be enough for the work - one will become the main axis, but the second will have to be cut into small parts and then welded to the base. This process will only take a few hours for a welder.

Next you need to drill holes in the main beam and bolt the center axle and hitch. Afterwards, you must check whether the trailer is moving while driving - for this you will need to install the wheels. It is best to carry out such a check at the initial stage of work, since problems may arise in the future, but for now the holes can simply be redrilled.

The next step is to attach the support leg and safety cable.

Weld a winch from a slightly thinner pipe - the design is complicated by a lanyard, which is intended to hold the boat in place during transportation. Otherwise, the crane mechanism itself will not last long. A pipe of the same thickness will go to the wing supports.

The same materials are used for keel blocks - several pairs of them are needed, since one will lead to damage to the bottom. The supports just need to be cut and welded in the designated places. The rollers on the axles must move freely because binding will cause damage.

Carry out the necessary tests, and then hang up the lighting equipment, and then paint.

The last step is to register the vehicle with the relevant government agencies.

Bottom line

The trailer is easy to assemble and will increase the vehicle's potential. You will transport cargo, the trunk and interior of the car will not be damaged. Car owners install a braking system on the trailer and install lighting. Entrust their installation to specialists; to do this, contact the service center.

- Next Water in the gas tank: causes, removal, prevention

- Back How to make a roof rack with your own hands?

- Aug 7, 2019

- Aug 6, 2019

- Aug 5, 2019

- Hyundai crossovers / News

Aug 5, 2019

- Aug 3, 2019

- Legislation / Taxes and fines

Aug 2, 2019

- April 13, 2019

- March 12, 2019

- Feb 17, 2019

- April 11, 2019

- July 27, 2017