Hunting, fishing and any active recreation on the water are impossible without an inflatable boat, which, in turn, must be delivered to a body of water. For this purpose, transom wheels are installed on PVC boats with NDND, with the help of which you can not only move the watercraft in equipped condition, but also launch it into the water. They cannot be used as a car trailer, they are required to be moved manually.

This part gets its name from the name of the supporting element of the PVC inflatable boat - the transom on which the motor is installed. The wheels are fixed on it, and simplify the process of moving the massive boat to and from the water. Even with a small weight of the craft, the use of this chassis is advisable, since it allows you to protect the bottom from damage.

Why are they needed?

It is very convenient to hang the motor directly next to the car and comfortably roll the boat into the water.

The weight of a PVC boat when fully equipped will significantly exceed its own weight. Let's assume that your boat weighs 50 kg, about 35 kg, the weight of the motor, a canister of fuel 25 kg, an anchor 10 kg, oars, seats, fishing rods, equipment, bait - another 40 kg, and adding 10 liters of water, which, one way or another otherwise, it will hit the boat, we get a total mass of 170 kg.

A very impressive figure. I gave this calculation so that you can imagine how much mass will need to be moved with the help of these wheels, and how they will facilitate human efforts.

Even if you have a small and light boat, the use of such chassis will be justified; you will save it when immersed in water, since coastal pebbles and sand wear out the bottom.

How to choose the right transom wheels

The choice should begin by determining the weight of your boat when fully equipped.

Let's calculate the weight of a loaded boat using the example of the popular CAYMAN 330 model:

- boat weight – 52 kg;

- Yamaha motor weight 15 – 36 kg;

- gasoline tank – 24 kg;

- 2 anchors – 12kg;

- food, bait, fishing rods, tools, fish... – 50 kg;

- water -10 kg.

The total came out to 184 kg. This means that wheels must be selected with a load capacity of at least 200 kg. If you have to transport a boat through sand and mud, then choose not only wide wheels, but also with the maximum possible diameter. The wheels will dig into the ground less.

Wheels can be with ball bearings and plain bearings. The last option is a bushing with an axle inserted into it. These bearings have high friction, especially under heavy load. If sand gets into them, the wheel can completely jam. But they are cheap.

Wheels with ball bearings do not have these disadvantages and have an excellent ride, but they are more expensive.

Types of transom wheels

Transom wheels come in two types:

- Removable , as the boat is delivered to the place, they are removed manually.

- Folding , while moving through the water they remain on the boat and are folded up like an airplane landing gear. They are also called quick-release, they are attached to the transom in one movement. No additional bolts or other fasteners are needed.

The size of the transom wheels should not exceed the dimensions of the transom, so that there are no problems with moving the boat on land or water.

General concepts

Today the situation has changed radically, and such a device will certainly be found in the arsenal of an avid fisherman or outdoor enthusiast. For those who have never encountered the installation of wheels, it will be useful to get acquainted with the advantages and disadvantages of this device. Judging by the name, it becomes clear that the wheels are attached to the transom, a special insert at the stern that serves to mount the motor.

Rubber and PVC boats are equipped with a transom made of pressed plywood, so this part is sufficiently rigid and suitable for installing additional equipment.

Transom wheels for PVC boats allow you to conveniently transport the boat from one place to another. Despite its compactness and functionality, this device is not used on long trips. This is the main disadvantage of transom wheels. There are several reasons for this:

- The absence of rolling bearings reduces the service life of the wheel; moreover, the bushings are not designed to rotate at high speed.

- The narrow rut makes the boat extremely rolly. Its overturning on the highway is fraught with an emergency situation.

- The low position of the boat above the ground increases the risk of damage to the material from objects that may lie on the road.

The above disadvantages do not at all mean that the device in question is a useless device. Often fishermen find themselves in a situation where moving the boat just a few meters is considered an important necessity and they simply cannot do without quick-release wheels.

To confirm the above, consider an elementary example. An ordinary PVC boat weighs about 50-60 kg. If it also has a motor installed, then another 25-30 kg should be added here. Equipment consisting of a fuel tank, anchor, and gear will add another 30 kg. As a result, moving a boat with a total weight of 120-130 kg from a car to a body of water will be very problematic.

It's not just about the force applied, but also about the likelihood of damage to the bottom from branches or stones. The best option is to install transom wheels, which can then be quickly removed or folded.

What are they made from?

Inflatable - they need to be inflated using a pump and ensure that they do not deflate. They can get punctured, although the rubber that is used to make them is thick, but often there is always a lot of broken glass or sharp metal objects on the shore. Despite the risk of puncture, inflatable tires are good because by changing the tire pressure you can adapt them to different soil conditions.

Cast ones are cheaper than inflatable ones, but the maneuverability on loose soil and sand is worse.

Plastic ones are stable and durable, but they pass very poorly over loose or loose soil. Although their appearance is very stylish, they are made of fiberglass.

Chassis disks can be made of metal or durable plastic.

Wheel stands are made of painted steel or stainless steel, very rarely aluminum. Stands can be straight or curved to suit different boat designs.

When purchasing wheels, pay special attention to the racks; they must be durable; high-quality stainless steel is the best material for them.

Bushing or bearing

According to the majority of inflatable boat owners, it is better to purchase transom wheels that have a caprolactane or fluoroplastic, in general, plastic sleeve in the structure, rather than bearings.

Most wheels are equipped with bearings made in China and are not protected from water. After launching they rust.

Many people simply replace the bearings in purchased wheels with bushings.

How to install transom wheels on a boat: step-by-step instructions

On the forums you can find a lot of useful tips on how to install transom wheels on a boat.

The photo shows several drawings shared by talented “homemade artists”:

We will show you how to install removable wheels with your own hands, and below there will be an excellent video on this topic.

To start, make sure you have:

- Level.

- Drill, screwdriver.

- Silicone sealant.

- And, of course, the set itself, consisting of transom wheels, a bracket and fasteners. It is better to use stainless steel bolts (usually these are the ones that come in the kit).

Instructions:

- Fitting. First you need to mark the location of the wheel and the bracket itself. To do this, we attach the entire structure and outline the bracket with a pencil, and also mark the places where we will drill holes. We do the same on the right side.

- We drill holes, insert bolts (at this stage we also do fittings before final assembly), try on the bracket and check how it will hold.

- We remove the bracket that we tried on, as well as the bolts.

- We install the plate from the bracket on the reverse side. We will use silicone to prevent water from getting into the drilled holes. Apply sealant to the plate and push a little silicone into each hole. Then we install the plate and the bracket itself, screwing the bolts into the holes.

- We install the nuts and tighten everything. It is better to use self-locking nuts so that the fastening does not loosen over time.

- We remove the remaining sealant that came out during tightening.

- Install the transom wheel.

- We do the same with the second transom wheel bracket.

- We check the quality of the installed wheels.

Details (and possible difficulties) of how to install transom wheels on a boat are shown in the video:

We hope our article on how to install transom wheels on a boat was useful and understandable to you. Share your experience in the comments. And remember that we have excellent motor boats with which any boat trip will be a pleasure!

Share link:

How to attach to a boat

The mounting procedure is not very difficult; the wheels are bolted to the outside of the transom.

All accessories for fastening wheels are sold complete with them; you only need tools: drill, screwdriver, glue, ruler.

The installation steps are as follows:

- Inflate the boat so that all elements of the boat are visually visible, get an idea of how the brackets will be positioned, and evaluate the mounting location.

- To ensure that both wheels are installed parallel to each other, mark using a ruler and draw a perpendicular straight line. Holes for the brackets will be drilled along it.

- Place the wheel mounts on the center line and mark the drilling points. To ensure that the fasteners are marked parallel to the bottom of the transom, it is appropriate to use a triangle.

- Drill four holes.

- Lubricate the holes and fasteners with silicone sealant.

- Tighten the wheel stands with bolts and washers.

Transporting a PVC boat on transom wheels

Transporting a boat on transom wheels is not difficult. You go down with your bow up, and you lift up with your stern down.

Try to avoid areas with soft, loose soil: mud, sand, silt. It’s hard on yourself and the wheels wear out more.

Do not use transom wheels to transport boats as trailers to a vehicle. They will not withstand a long journey. But it’s hard to even imagine how the inspector will like it. The wheels and fastenings are designed to transport the boat only over short distances and only with manual human traction.

Which ones to choose

The cost depends directly on the size of the wheels.

It is necessary to choose wheels taking into account each specific boat.

Short wheels - for a small PVC boat up to 3.5 meters, a hard bottom is required. The average price is 4000 rubles.

For a small boat with a hard bottom, from 3.5 meters in length, “Standard” economy wheels are suitable, at a price of about 4,000 rubles.

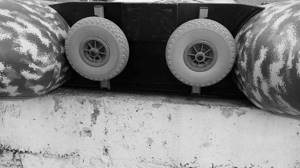

Reinforced wheels, when there are 2 wheels on an axle, are intended for heavily loaded boats, they have good maneuverability on difficult soil, their value will already be around 6,500 rubles.

Certain types of chassis are produced for boats with a low-pressure bottom of the “Solar” type.

There are wheels with a German folding system, they are also called transformers ; they do not rise up, but descend to the transom.

How to install wheels yourself?

The process of installing wheels on a PVC boat is quite simple; the detailed algorithm of actions is as follows:

- The structure is applied to the transom at an angle of 90° with the wheels parallel to each other to prevent bending; The lateral boundaries are marked.

- The lower limit of the fastener is measured and marked.

- The fastener element is superimposed on the marked boundaries so that the locations for the holes can be marked.

- Holes are drilled at the marked points; at this stage, accuracy is important.

- The holes made and the places where the fastener element comes into contact with the transom are treated with sealant to prevent the accumulation of moisture and subsequent rotting, as well as to ensure a tight adhesion.

- The structure is secured with bolts, after which the nuts are tightened tightly. You shouldn’t tighten them all the way right away; they need to be gradually tightened one at a time to the required state.

- The wheel can be inserted into the securely fixed mount. Initially, a frame is threaded into it into which it should be inserted.

- The bolt required to secure the wheel is threaded through the pipe, and it is secured with a nut.

- The position of the wheel can now be changed depending on whether the boat is in the water or on land. Its location will be maintained using a special clamp installed on the mount protrusion.

- The algorithm of actions for installing and fixing the position of the second wheel is similar.