What is a snowmobile? This is an indispensable assistant in moving through snowy forests, fields and other areas. From a technical point of view, this is an automatic vehicle that has runners instead of wheels and is driven by a classic internal combustion engine and propeller.

Such sleds reach speeds of up to 140 km/h. Speed is the main advantage of snowmobiles over snowmobiles. And if you equip it with a cabin and improve the suspension, then you won’t find more comfortable movement in deep snow. The design is so simple that it is not difficult to make one yourself using available materials.

Technical characteristics of snowmobiles

In terms of technical properties, snowmobiles differ little from chainsaws. However, with low thrust it is possible to develop high speed.

- 4700 rpm engine power;

- 15 hp;

- 62 kg - maximum propeller thrust;

- screw diameter 1300 mm;

- 2300 — maximum number of propeller revolutions per minute;

- 1.85 — gear ratio;

- 0.68 sq.m. – area of the sliding surface of the runners (skis);

- 40-50 l. — volume of the fuel tank;

- 40-50 km/h – maximum speed;

- 50-70 km/h - maximum speed on packed snow;

- 75-80 km/h - maximum speed on virgin snow;

- 100-110 km/h – maximum speed on ice;

- 90.7 kg – weight without driver (dry weight);

- 183 kg – total curb weight.

Load capacity

Carrying capacity refers to the weight of the driver, passengers, cargo and additional fuel. The snowmobile carries 1-5 passengers on board. The weight of cargo on board reaches 300 kg.

Thus, snowmobiles become useful in moving goods and people between remote settlements in snowy areas. They will also become indispensable during a hunt to drag away a carcass or get to the desired square.

Range

If a snowmobile has a small-displacement engine, then it has one standard tank of 40 liters. At cruising speed it is possible to cover up to 300 km.

Fuel reserve

The amount of fuel in the car directly depends on the volume of the fuel bank. On average it is 40-50 liters. In relation to weight and occupied volume, this is considered a standard that harmoniously distributes the load.

Therefore, it is possible to cover long distances without refueling. In addition, an additional canister of fuel with a volume of up to 20 liters is taken on board, and when the reserve in the tank is used up, add an additional one and get to your destination.

Speed

On compacted snow, the speed of the sled is 40-50 km/h. When driving in deep snow and virgin soil, 75-80 km/h. Nast allows you to accelerate to 110 km/h. However, it is dangerous to move at such a speed, the stability of the machine is reduced and there is a risk of capsizing.

Engine braking and starting system

The brakes on a mechanized sled are installed in the form of a scraper on the rear ski. When the driver presses the brake pedal using a cable system, the scrapers are lowered to the ground and slow down.

The engine is started either by spinning the flywheel using a cable, or by using the ignition system via a key.

How to make a snowmobile

Making a snowmobile yourself is not difficult. However, this will require time, tools, blank materials and drawings. Accurate calculation and compliance with the requirements imposed by the laws of physics for machines moving on snow and on a screw drive depends on the safety and durability of the unit.

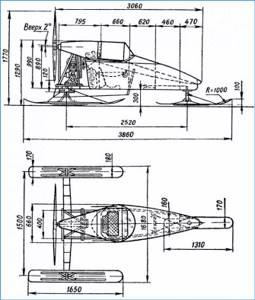

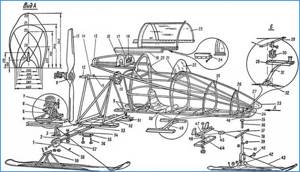

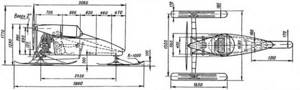

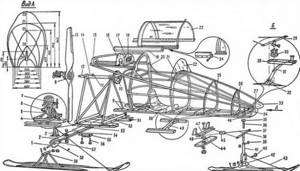

Frame

Making your own snowmobile starts with the body. It consists of a frame and casing. For normal strength of the frame, it has two spars. The standard dimensions for them are 35x35x2350 mm. The structure is strengthened with power stringers measuring 25x16x2850 mm and five supporting stringers (20x12x2100mm). The body also has a front part and an engine compartment at the rear. To streamline the body towards the front, the cabin is narrowed.

Throughout the entire hull, 4 frames (circular beams) are installed at equal distances from each other. They are monolithic and made of 10 mm thick plywood. The widest frames for reliability and stability of the structure are reinforced with transverse beams in the spacer on the upper part.

First, the lower frame is installed on which the frames are mounted. They are equipped with spacers, attached to the frames with corners. Then the stringers are attached. The frame is glued with casein glue. The joints are wrapped in gauze and soaked in glue (or a bandage already soaked in glue).

The hull sides are covered with plywood sheets. A duralumin cladding is installed on top. A driver's seat made of plywood or a ready-made plastic one is installed inside the cabin. There is a luggage compartment behind the driver's seat. It stores tools, consumable parts, an additional fuel canister and the driver’s personal belongings.

Propeller installation

Installing a propeller engine installation is a more complicated process than assembling a cabin. A motorcycle engine, for example, IZH-56, is often used to drive the propeller. A bearing is installed on the frame, into which the propeller shaft is then placed.

Using two brackets, the engine is attached by four struts to a wooden plate measuring 385x215x40 mm. The slab is sheathed on both sides with plywood sheets 5 mm thick. The legs of the struts are reinforced with duralumin corners.

To subsequently adjust the tension of the V-belt, a plate of plywood or textolite is placed between the channels and the load-bearing plate. The engine is cooled by a fan, which is placed on the crankcase using a bracket.

Chassis

The third stage of assembling a homemade product is the installation of the chassis. To make skis, 10 mm thick plywood is used. Birch timber is used for reinforcement, and the top of the ski is covered with stainless steel sheet metal. The fastening mechanism of the ski to the body, called the “hog”, is attached with M6 bolts.

The ski has an undercut made of a steel tube with a diameter of 8 mm. The ends of the tube are flattened. They are attached in the middle under the hog. The function of undercuts is to maintain machine stability when turning.

The front of the ski is curved. To bend the plywood, it is heated in boiling water and shaped using a jig. A metal plate is installed for preservation. The ski spring is made of wood and consists of three parts.

The lower part is made of birch, has dimensions of 25x130x1400 mm and an axle shaft is attached to it. The middle and upper parts are made of pine. Together they are secured with a duralumin sheet and M8 bolts. The front ski has a kind of shock absorber that prevents it from digging into the snow when moving.

It is a rubber band. Due to the fact that the rear part of the machine is heavier, together with the harness, the ski does not fall into the snow and remains with its nose slightly above the horizontal axis.

Acceleration and braking of the snowmobile occurs by pressing on the corresponding pedals, and steering is provided by the steering wheel.

To simplify the assembly of the structure, it is better to attach a ready-made propeller. Making your own is difficult and not everyone can do it.

Equipment for homemade snowmobiles

Screw-driven sleds are equipped with a variety of devices. However, the fuel level indicator, tachometer, speedometer, ignition switch and ammeter are usually installed on the front panel, made of PCB sheet.

There are many more devices that can be installed, but the feasibility is not justified. Inside the cabin there is a lever for the air and throttle valves of the carburetor. A mirror is installed on the left side, and a visor is installed on the top of the cabin inside.

Snowmobile with chainsaw engine

The design of a snowmobile driven by a chainsaw engine is an even simpler machine than the snowmobile described above. However, the ease of their manufacture is offset by a negative factor - you won’t go far with them.

To move normally across snowy expanses, you need an engine with at least 12 horsepower, while a chainsaw has 4 horsepower. The principle of installing such an engine is similar.

It’s convenient to move across a frozen body of water from hole to hole on such a unit, but making a foray somewhere further is no longer possible.

technical specifications, how to do it yourself

An snowmobile is a unique vehicle; this type of transport has no equal in cross-country ability on snow. Therefore, they are considered an indispensable assistant for any fisherman. In terms of design, it is a vehicle with skids for driving on snow, and it moves with the help of an aircraft propeller that rotates a gasoline engine.

The sled is capable of reaching speeds of up to 150 km/h, which is an undeniable advantage over snowmobiles. With a cabin and soft suspension, a snowmobile can be the most comfortable vehicle after a car. But the car will not drive through impassable spaces covered with snow.

At first glance, everything is very complicated, but if you get into it, there are no difficulties, and you can really make a snowmobile yourself using available materials, without spending a lot of effort.

Technical characteristics of snowmobiles

A snowmobile is essentially a chainsaw, but with relatively little power it can reach high speeds. For example:

- Engine speed – 4700.

- Power – 15 hp

- The maximum propeller force is 62 kg.

- Screw diameter – 1300 mm.

- The highest number of propeller revolutions is 2300.

- The gear ratio is 1.85.

- The area of the runners is 0.68 square meters.

- The capacity of the fuel tank is 40-50 liters.

- The highest speed is 40-50 km/h.

- The highest speed on hard snow is 50-70 km/h.

- The highest speed on snow, in open spaces is 70-80 km/h.

- The highest speed on snow crust is 100-110 km/h.

- Maximum weight (without driver) – 90.7 kg.

- Maximum weight with cargo – 183 kg.

Load capacity

Load capacity is the total weight of the vehicle with passengers and equipment. The snowmobile can accommodate up to 5 people. Therefore, when fully equipped, the weight of the vehicle can reach 300 kg.

In other words, a snowmobile is a fairly capacious type of transport that allows you to transport people and cargo over considerable distances in conditions of total snow cover. They may also not be replaceable in fishing or hunting conditions.

Movement range

If the vehicle does not have a powerful engine, then one tank with a capacity of 40 liters is enough to travel up to 300 km.

Fuel reserve

As a rule, a standard tank of 40-50 liters is installed. In addition, on the road you need to take a container of fuel with a volume of 20 liters. This fuel is quite enough to cover a significant distance without refueling. In any case, you need to correctly calculate the fuel supply, since in the snowy wilderness, it is unlikely that you will be able to refuel.

Travel speed

On ordinary compacted snow, a snowmobile can be accelerated to 50 km/h, and on untouched, long-standing snow – up to 80 km/h. The presence of hard crust allows the structure to accelerate to 110 km/h. At such a speed, there is a danger of capsizing, since the stability of the snowmobile decreases.

Design of brakes and engine starting

Since snowmobiles are an exclusive type of transport, the brake system has a far from classical design. The design of the brakes resembles a kind of scrapers that are mounted on the ends of the rear skis. They are activated by cables coming from the brake pedal. When you press the pedals, the scrapers go down, which slows down the speed of the snowmobile.

Features of snowmobiles for fishermen

A snowmobile for fishermen in winter, as useful as a boat in summer, although you can’t go very far with a watercraft in summer. And, nevertheless, on a snowmobile you can safely get to the center of any body of water, if there is strong ice. Although, if you compare it with a car, you can travel on a snowmobile in deep snow, which you cannot do with a car. In addition, the thickness of the ice required is somewhat less, since the snowmobile is much lighter.

How to make a snowmobile with your own hands

As practice shows, making a snowmobile is not so difficult, although you will have to stock up on time, tools, materials for work and drawings. At the same time, it is necessary to maintain precision in manufacturing, since here the laws of physics and aerodynamics come to the fore. The quality operation of all units, and therefore the durability of the vehicle, will depend on such knowledge.

Housing design

The production of snowmobiles begins with the manufacture of the body, which consists of a frame and skin. To ensure that the frame has significant strength, the design has two spars. They have the following dimensions: 35x35x2350 mm. In addition to them, the design includes 5 power stringers, measuring 20x12x2100 mm. Plus, the body has a front compartment and a rear compartment where the engine should be located. The body must be aerodynamically shaped, so it tapers at the front.

The entire hull is reinforced throughout its entire length with four frames located at equal distances from one another. They are made of solid plywood, 10 mm thick. For greater reliability, frames, especially wide ones, have transverse reinforcement with special beams.

First of all, the lower frame is mounted, on which the frames are installed. Spacers are also mounted here, which are attached to the frames with corners. After this, the stringers are secured. The frame is glued with casein glue. The joints are fixed with gauze, after which these places are generously saturated with glue. Another option is also possible: first the bandage is soaked in glue, and then it is wrapped around the connection points.

The body is sheathed with sheets of plywood, and duralumin sheathing is mounted on top. The driver's seat can also be made of plywood or a factory-made plastic one installed. In the rear, behind the seat, there is a luggage space where tools, spare parts, a container of gasoline, and the fisherman’s personal belongings can be stored.

Propeller system

The propeller engine installation requires a more serious approach than assembling the cabin and hull. To rotate the propeller, they mostly take the engine from the IZH-56 motorcycle. The propeller shaft is mounted on a bearing, which is located on the frame.

The engine is mounted on a wooden plate using two brackets and four struts. The plate has dimensions of 385x215x40 mm. It is advisable to sheathe the slab on both sides with plywood, 5 mm thick. Duralumin corners are attached to the legs of the struts.

To make it possible to adjust the V-belt transmission to the screw, a plate made of plywood or textolite is provided between the channels and the plate. The engine is cooled by a fan, which is mounted on the crankcase using a bracket.

Travel suspension

Installation of the chassis is a continuation of the 2 previous stages. Plywood, 10 mm thick, is used as skis. To strengthen them, a thicker beam is used, and the upper part of the ski is sheathed with stainless steel. The entire ski mechanism is attached to the body using M6 screws.

The design of the ski also consists of an undercut, which is made of a pipe with a diameter of 8 mm. The ends of the pipe are flattened. The pipe is attached in the middle part of the mount under the “hog”. Undercuts allow the snowmobile to remain stable when turning.

The front of the ski flexes. To do this, the ski is placed in boiling water (only the part that needs to be bent) and bent using a device (slipway). To ensure that the front part of the ski retains its shape, a metal plate is installed. The ski spring is made of wood and has three parts.

The lower part is made from birch, which has dimensions of 25x130x1400 mm. The axle shaft is attached to it. The upper and middle parts are pine. Together they are connected with M8 bolts and duralumin sheets. There is a special shock absorber in the front of the ski, which prevents the ski from digging into the snow when moving. It is made of a rubber band. The back of the snowmobile is already heavier, and together with the harness, the ski is always directed upward.

Acceleration of the snowmobile's movement is carried out by pressing the corresponding pedals, and changing the direction of movement is carried out by means of the steering column.

To avoid any problems with the operation of the snowmobile, it is better to take a ready-made propeller, since it is very difficult to make it yourself, especially the first time.

How to equip a snowmobile?

Any vehicle must have several mandatory instruments, such as a speedometer, tachometer, ammeter and ignition switch. A fuel level indicator wouldn't hurt either. All main instruments are installed on the front panel made of PCB.

You can install some additional devices, but only if there is at least some sense. Well, for example, a GPS navigator, which may be needed if the path is long and the places are unfamiliar.

There should also be a carburetor air and throttle lever in the cockpit. It is advisable to install a rear-view mirror on the left side of the cabin, and a visor on top of the cabin.

Snowmobile based on a chainsaw engine

This design is much simpler than the design described above. The engine used here is a chainsaw motor. Despite its simplicity, it is unlikely that anyone will decide to go fishing on such snowmobiles.

To travel long distances, you need a motor with a power of about 12 hp, and the motor power of a chainsaw is only 4 hp. The installation principle is the same as in the first case.

If the reservoir is not far away, just a few kilometers away, then you can go fishing on such snowmobiles, equipping them with a place to move fishing equipment.

Safety precautions

A design such as a snowmobile requires special attention, since there is a rotating part that poses a potential danger to others. This part is a rotating screw or, as it is called, a propeller. To prevent a person from getting into the area of its rotation and being injured, it must be hidden in a special casing. In addition to the fact that this casing will protect those around you, it will also protect the screw itself from foreign objects that could simply break it.

During the work, all dimensions given in the drawings must be strictly observed. Self-production requires great care: it is necessary to check every bolted connection, especially on skis, since they experience the main load.

During operation, you should regularly check the mounting points, as well as the propeller itself, for defects. In addition, you should pay attention to the normal operation of the engine, the presence of fuel and the oil level. This is the only way to count on trouble-free operation of a homemade device, especially if it is designed for long-term operation.

Snowmobiles can make a fisherman’s life easier, and quite significantly, especially in snowy areas. This is the only vehicle, other than a snowmobile, that can be used to travel long distances in such conditions without problems.

fishingday.org

Safety precautions

First of all, you need to pay attention to the normal protection of the screw from the unwanted entry of foreign objects into it. That is, a person or animal standing next to the machine should not be harmed by a rotating propeller. To do this, it is installed in a special protective mesh box.

During the assembly of the snowmobile, it is necessary to strictly adhere to the dimensions and requirements of the drawings, if they are taken from an official source. If production is carried out independently from scrap materials and your own ideas, then you should pay attention to the correct level of tightening of bolts and nuts. They should hold the parts together tightly enough, but not overtighten, so that during use they do not crack or fall apart while moving.

The ski should have a raised nose so as not to dig into the snow. The engine must be in good working order and have sufficient fuel and oil. The propeller must be constantly checked for defects.

Aerosleighs make life ten times easier for a fisherman who wants to make an excellent catch on a large body of water in winter. A properly planned and manufactured snowmobile will not only delight the owner with its practicality, but will also help with housework. Therefore, for a person who often faces winter forays into untouched nature, a snowmobile will turn into the best assistant.

Types of snowmobile enginesAmateur V.P. Rumyantsev made a gearbox (Fig. 50) for the GAZ-M1 engine, using ready-made gears of the third and fifth gears of the ZIL-150 car’s gearbox. The gearbox housing is welded. The gears are mounted on rollers mounted on ball bearings. The presence of a gearbox and the installation of a propeller on a special shaft made it possible not to create a thrust mechanism.

When using IZH-350, IZH-49 and IZH-56 engines with a chain drive to the propeller shaft, the chain from the drive sprocket upwards is hindered by tides on the crankcase and on the cover. These tides must be cut down in such a way that the chain goes up freely.

I. L. Sinitsyn (Altai Territory) when installing the IZH-49 engine, completely removed the crankcase cover (Fig. 51), thereby reducing the weight of the engine.

Fig. 50. Gearbox for the GAZ-M1 engine.

Many amateurs use “PD-10” and “PD-10M” starting engines (from tractors “DT-54”, “KD-35”, “KDP-35”, “Belarus” and etc.). When operating on a tractor, they are cooled with water from a common cooling system with the main engine. On snowmobiles, it is more profitable to adapt them for air cooling.

The cylinders of the IZH-49 and IZH-56 motorcycle engines are suitable for the PD-10 and PD-10M engines in all connecting dimensions. When replacing cylinders, the installation of the piston rings should be checked. Their locks and clamps, which protect the rings from turning on the piston, should not come into contact with the suction and exhaust ports of the cylinders, as this can lead to breakage of the rings, scuffing of the piston and cylinder, and engine jamming.

The pins on the piston must be rearranged, and the ring locks must be deployed accordingly. The gap between the piston and cylinder should be 0.12 mm. If it is smaller, the piston is ground against the cylinder until the nominal clearance is obtained. Grinding is carried out with oil and very fine emery dust. Check the gap size with a special feeler gauge.

Rice. 51. Installation of the IZH-49 engine with the crankcase cover removed.

When replacing a cylinder, it should be taken into account that the cylinder of the IZH-56 engine is much lighter in weight than the cylinder of the IZH-49 engine.

During assembly, all engine parts in detachable, fixed joints are placed on thin gaskets, lubricated on both sides with acetone or oil paint. This ensures the crankcase is sealed. Without good crankcase sealing, the PD-10 two-stroke engine will lose power.

Two bearings are installed on the crankshaft from the flywheel side - roller and ball No. 206. The cover is ground off. The carburetor can be used from the PD-10 and IZH-49 engines, but the diameters of the nozzle flow sections must be increased.

Some snowmobile builders, when converting the PD-10 engine, remove the flywheel to make it easier and install a propeller in its place.

This should not be done. Removing the flywheel breaks

balancing the engine, as a result of which it quickly wears out, and sometimes this leads to breakdowns.

To ensure good starting performance at low temperatures, one amateur from the Kemerovo region installed a second magneto and a second spark plug on the PD-10 engine. He screwed the spark plug into the socket of the decompressor removed from the cylinder, and put the second magneto in place of the speed controller, having previously bored out the intermediate crankcase plate to the diameter of the magneto seat and welded an eyelet to it for a fastening bolt with a thread diameter of 6 mm. In addition, on the engine crankcase he sawed off the sidewall that interfered with the rotation of the magneto accelerator.

The same amateur installed a generator from the M-72 engine on his engine, making it drive from an intermediate gear. The generator provides illumination of the road while the snowmobile is moving at night.

Many builders install PD-10 and PD-10M engines with the cylinder down (Fig. 52). The engine works quite normally in an inverted position, and this installation provides a number of significant advantages: the center of gravity is lowered, the parking height of the car is reduced, and the location of the gasoline tank is improved, since the carburetor is significantly lowered down.

Some hobbyists boost the PD-10 engine. They grind down the cylinder mating flange by 1.5-2.0 mm, reducing the volume of the combustion chamber, that is, increasing the compression ratio. This allows you to increase engine power to 12-14 hp. With. But in this case it is necessary to take “A-70” or “A-72” fuel.

Rice. 52. Installation of the PD-10 engine with the cylinder down.