Fishermen, hunters and winter sports enthusiasts use snowmobiles to travel to the best vacation spots. Even inexpensive models of such equipment cost about a hundred thousand rubles, often more. Those who want to save money can assemble a homemade snowmobile on tracks in a regular garage workshop. The cost of parts for construction does not exceed 40 thousand rubles.

Snowmobile device

Homemade snowmobiles are built on caterpillar tracks. The tracks are driven by an internal combustion engine mounted on a rigid metal frame. They are supported in working position by wheels and special rollers. Main options:

- With a solid or fracture frame.

- With rigid or shock-absorbed suspension.

- With an engine from a walk-behind tractor or from a stroller.

Short skis are used for steering. Light snowmobiles (weighing up to 100 kg), designed to travel at a maximum speed of up to 15 km/h, do not necessarily require a braking system. They stop easily when engine speed drops. make a homemade snowmobile on tracks using the following algorithm:

- Selection of engine, calculation of frame and chassis.

- Frame assembly by spot welding.

- Steering device.

- Installing the engine in the design position on a temporary mount.

- Checking the structure for resistance to capsizing.

- If the test is successful, the frame is completely welded and the engine is installed.

- Installation of drive system, axles.

- Assembly and installation of tracks.

- Installation of body parts.

After this, final tests are carried out. If the snowmobile drives normally and does not tip over, then it is driven into the garage and disassembled. The frame is cleaned of rust, painted in 2 layers, the remaining elements are finished, and then a homemade snowmobile on tracks is assembled with your own hands.

Homemade snowmobile from a walk-behind tractor

This transformation is especially popular today. The walk-behind tractor can be used either partially or completely. In the first case, a supporting frame with a rear axle is welded to the unit (engine with steering fork and wheels). The most difficult stage in this case is the transformation of the working shaft of the walk-behind tractor into a drive gear.

A homemade snowmobile from a walk-behind tractor with partial use of parts is more versatile. In this case, only the engine and steering fork are removed from the “donor”, to the lower part of which skis are attached instead of wheels. The motor itself can be located in the rear part of the structure.

It should be noted that the engines of the main part of the walk-behind tractors are designed for the weight and pressure of the wheels, which is several times less than the caterpillar one. Therefore, in order to avoid increased wear of parts and fuel consumption, it is better to equip such a snowmobile with low-pressure wheels.

[sc:ads5]

Engine selection

Gasoline engines are used for walk-behind tractors or strollers. Engine speed is controlled by a throttle handle located on the steering wheel. To make a homemade tracked snowmobile with your own hands, the easiest way is to use ready-made small-volume engines for walk-behind tractors with pre-installed:

- Fuel tank.

- Ignition system.

- Reduction gearbox with a ratio of 1:2.

- Centrifugal clutch, automatically activated when the speed increases.

The power of these engines does not exceed 10 horsepower, but they are easy to install: the technician does not need to separately assemble the ignition system, connect fuel pipes, adjust the clutch, etc. There are different options on the market:

| Brand | Model | Power, l. With. | Volume, cm3 | Weight, kg | Approximate price, thousand rubles. |

| Kipor | KG160S | 4,1 | 163 | 15,5 | 20−25 |

| Sadko | GE-200R | 6,5 | 196 | 15,7 | 15−20 |

| Lifan | 168 FD-R | 5,5 | 196 | 18,0 | 15−20 |

| Zongshen | ZS168FB4 | 6,5 | 196 | 16,0 | 10−15 |

| Nomad | NT200R | 6,5 | 196 | 20,1 | 10−15 |

| Brait | BR-177F-2R | 9,0 | 270 | 30,0 | 10−15 |

| Honda | GX - 270 | 9,0 | 270 | 25,0 | 45−50 |

If it is not possible to purchase a ready-made engine from a walk-behind tractor, then you can use an engine from a stroller. Such engines are 10-15 horsepower more powerful, but require self-assembly. The system includes:

- Engine.

- Clutch.

- Gearbox.

- Gas tank (volume 5-10 liters).

- Muffler.

- Generator.

- Electronic ignition switch and coil.

Some of the elements will come from old motorcycles (“Minsk”, “Vostok”, “Java”, “Ural”). The gas tank is located as close as possible to the carburetor to reduce the length of the pipes.

How to make a snowmobile with a Lifan engine with your own hands?

Riding with children on a beautiful, homemade snowmobile is always exciting. However, a successful purchase will hit the family budget hard, so it makes sense to think about how to assemble special equipment yourself using drawings, auto parts and your own ingenuity.

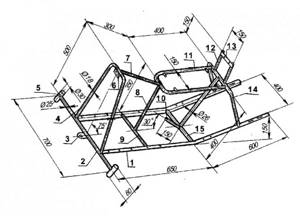

Frame and body

Before work, it is recommended to draw up a drawing of the frame. The structure is welded from a square pipe 25 x 25 mm with a wall thickness of 2 mm. For a payload of over 150 kg, the section size is increased to 30 x 25 mm. The loading area and body elements are covered with plywood. The seats are selected with a hydrophobic coating.

In the center of the fracture frame there is a hinge that allows rotation around a vertical axis. The maximum rotation angle is limited by welding metal plates. The front half is used for steering, and the engine is placed on the rear half frame.

The solid frame is welded in the form of a rectangle, inside of which axles and tracks are located. The engine is placed in front on a special platform, rigidly welded to the rest of the frame. In both cases, the motor is installed in the transverse direction (the shaft faces the end).

Chassis

Light snowmobiles designed for riding on loose snow are equipped with a hinged suspension made from an extended M16 nut. This is a lightweight design with a simple structure that does not provide comfortable driving characteristics of the homemade product.

Snowmobiles on tracks intended to travel on compacted snow must be equipped with shock absorbers (from a motorcycle or moped). Shock absorbers are installed where skis and axles are attached to the frame. The suspension travel is selected so that moving elements do not touch the snowmobile body during operation.

Steering wheel and skis

The steering is output to two front skis according to a scheme structurally similar to the suspension. It is made from a threaded stud installed in an extended M16 nut, rigidly welded to the frame. The steering wheel from a moped or motorcycle (“Minsk”) is used.

In total, the design uses 3 plastic skis from a children's scooter (or homemade ones from 3 mm thick plywood). A pair of front skis is used for taxiing. Skis up to 1 meter long are used and, if necessary, reinforced with a steel pipe and plate.

The third ski is a support ski, used to maintain the belt in working condition. It is shorter than the others, located between the bridges (in the center). A T-shaped beam is attached to the support ski, rigidly welded to the frame. On top of the beam are freely rotating rollers for the tracks. Installation of such a structure is not necessary if the track does not sag.

Construction of bridges

Bridges are located under the loading area. One bridge requires 2 inflatable wheels from a garden cart and a metal rod. The wheels rotate freely and have no drive. In snowmobiles built on the basis of motors from walk-behind tractors, the wheels are inflated halfway. Clamps are welded to the outer ends of the wheels, with the help of which the axles are attached to the frame.

The front axle is stationary, its clamps are rigidly welded to the frame. The rear axle must move freely along the frame as it serves to tension the track. Its clamps provide friction tightening from M10 bolts, securing the bridge in the working position.

Construction began with the manufacture of the frame:

The frame is assembled and welded from a profile pipe according to our own drawings.

Were purchased:

engine, caterpillar, rollers, driven and drive shafts with sprockets, drive and driven variators (drive variator “Safari”).

After this, the assembly of the chassis began:

The build process has begun:

Installing a driven variator with a belt on the frame.

Assembling the front suspension, installing the engine and adjusting the variators. The engine is mounted on rubber mounts for less vibration.

All components and assemblies were installed in their places, after which the production of the skins began:

The engine compartment linings are made of plastic (polypropylene).

The seat is made on a metal frame with soft padding and covered with artificial leather.

And here he is, handsome! Standing in the yard and waiting for snow