Purpose and principle of operation of the ice auger

The main purpose of a classic ice drill is to drill cylindrical holes in ice to a depth of up to 1 meter, which distinguishes this tool from an ice pick.

During operation, the noise emitted by this device is at a fairly low level, which is a significant argument when fishing.

The device and principle of drilling ice is similar to the rotators used in construction.

For this reason, some craftsmen use an ice drill when installing poles, which leads to damage and complete unusability of the knives.

There are models with replaceable augers, which allows, when installing the appropriate equipment, to drill both ice and soil.

The only difference is that when drilling ice, the knives do not cut off its layers, but break off pieces ranging in size from grains of sand to heavy stones.

With an ice screw on spring ice

On one of the last fishing trips, perch was caught happily, but, as always happens in early spring, there is one very serious obstacle between the prey and the fisherman - ice that is a meter (or even more) thick. This kind of ice is accurately characterized by the phrase: “under the arm.” Although physical strength matters when drilling a hole in spring ice, it is not the most important thing. Skillful handling of the ice auger and preliminary preparation of it at home play a decisive role.

Heavy ice time begins around mid to late March. Usually this period of time in Siberia is not yet the last ice, which means you can’t expect the fish to look for your bait on its own. The fisherman is forced to drill hole after hole. Very often, many people run out of strength and desire on the 5th-6th hole, and they spend the whole day catching only them and returning home with a bad catch. Of course, there is practically no alternative to a motorized drill during this period, but there are still time-tested methods for drilling holes with a hand-held ice drill in spring ice.

Let's start with the fact that it's all the little things that matter here. It’s like a stayer’s race: you haven’t calculated your strength over the distance, and just before the finish line you can just “stand up.” In other words, if you drill through thick ice competently and sparingly using energy, then by and large it is not so “deadly.” If I drill 4-5 holes at a time on the first ice, now I do no more than two. But two holes in one go is also a result that allows you to fish a fairly large area of the reservoir in a day.

Stages of drilling a hole

To begin with, it would be good to clear the area for the hole from snow, since snowdrifts 30 and sometimes 50 cm high cause additional inconvenience when drilling, and also take away already precious centimeters from the height of the ice drill. You can clear a place for a hole with your foot, but in the spring the snow becomes quite dense, and in many places where they previously fished, it completely turns into almost a monolith. Scattering such snow with your foot is almost more labor-intensive than drilling a hole. Therefore, I always carry a small and light wooden spatula with me. You can clear the hole from snow in just a few seconds. As a rule, I clean “windows” for several holes at once. I don’t forget to make a recess for the winter box, since sitting on the “chair”, which stands at the very top of the snowdrift, is uncomfortable.

There is one more nuance: when choosing a place for a hole, try to find clean, ice-free ice. Usually such places are either closer to the shores, where the ice subsides less, or where fishermen often fish - it is already so “trodden” that there is no ice. In such places it is easier to drill and catch. Drilling spring ice with domestic ice drills with straight blades, and even in water, let’s say, is a bit difficult.

Choosing a drill

The hole is ready. Now the ice auger needs to work. You need to choose a drill for spring ice with the smallest possible diameter; 100 or even 80-90 mm is quite enough for catching roach or perch weighing up to 500-700 grams. The longer the auger, the better: you can pull out the drill less often when drilling and shake it off ice chips. Not only Scandinavian ones, but also domestic ice screws, specifically those made in Barnaul, can cope with this task quite well. By the way, they now have a “drill match” with a diameter of 80 mm in their line. I can say that when using our Tonar and the Swedish Mora of small diameters, there is no significant difference in drilling speed between them.

Well, what should you do if you need to catch bream, large pike using spoons or using jigs? Here you already need a diameter of 130-150 mm. To drill such wide holes, it is best to use Scandinavian-made ice drills with spherical blades. And the point is not only that spherical blades drill dry and wet ice equally well, but also that the hole will freeze overnight, and with such blades it can be easily re-drilled. This is very convenient, especially when you are faced with a choice: drill a new hole in a meter of ice or “uncork” the old one in a few seconds. In addition, with spherical blades you can try to drill out old holes left by other anglers who fished a day or even two ago. Is it worth trying to drill out old holes if, by all indications, they are at least a few days old? I am sure that two days is the limit. At temperatures below –10°C, within 24 hours the hole freezes almost to the base, and there is no point in drilling it out.

If you feel that the ice auger at the end of drilling a hole begins to get stuck, get stuck and does not go any further, then you need to immediately remove it and shake off the ice crumbs. The problem is almost certainly ice frozen on the auger. You need to carefully tap it with a wooden stick or the handle of a scoop so as not to damage the paint on the auger, otherwise the ice will freeze much more firmly on the bare metal. Having drilled the hole to the end and feeling that the ice drill has reached the water, the first movement is not to lift it up, but, on the contrary, to push the ice plug down, under the ice, and only then lift the drill. This is the easiest and most correct technique. Sometimes it is simply impossible to lift up a layer of wet ice crumble, then you should push it down and swing the ice screw up and down a couple of times in the hole. “Pumping” the hole more than once or twice is not recommended. The light suspension in the water does not let the sun's rays pass through the ice, thereby scaring the fish away from the hole less. In addition, I almost always try to fill the hole with dry snow and, having made a hole in it, fish in a darkened hole. It won't get any worse, but in half the cases it turns out to be useful - the catch from one hole is much larger. When fishing with spoons and a balancer, I don’t “pump” the hole at all - the baits are heavy and easily penetrate any slush.

Drilling wet ice

By the way, you can “teach” our Russian ice drill to drill into wet ice. Firstly, you can use special knives for wet ice. Here, of course, you first need to make sure that the ice is wet. Very often it is dry, and the ice that appears on top is deceiving. When there is little snow and severe frosts, the emerging water quickly freezes, but in the spring this ice can remain for a very long time, especially in the middle of lakes and rivers, where the ice subsides most of all. Dry ice under ice can be drilled with regular blades.

A more typical situation for spring is when the ice is wet and there is snow porridge on top. Here you need either special blades, or, in their absence (and for some drill diameters such blades are simply not produced), you can “make” the classic ones work. The fastening screws are loosened and matches or pieces of wire (aluminum or copper, but without insulation) with a diameter of 1.5-3 mm are placed under the “heels” of the knives. Then you need to tighten the screws firmly. By increasing the blade angle, we make it easier to drill through wet ice. A wire or match is enough for one fishing trip, but for convenience it is better to make stronger conical gaskets, for example, cut from dense rubber.

It is more practical to drill wet ice in several passes, periodically removing the drill and removing ice chips. In addition, drilling through thick ice without stopping is dangerous: under the pressure of ice chips and water that gets into it, the ice drill will simply get stuck in the hole. You can't take it by force. Before my eyes, one fisherman pulled out an ice auger like this?... and got to the point where he pulled out the auger with the auger folded into an accordion. So it’s better to drill 20-30 cm, “pump” it with a drill, throw out the ice chips, drill 20-30 cm again, and so on several times until the finish.

The easiest way to drill is wet ice, on which there is no longer any snow or ice. This is the last ice. Such ice can be drilled with absolutely any blades, but it is very dangerous, and you can fall under it quickly and without first crunching the ice. When moving on the last ice, carry the ice screw in front of you. If you fall through, you will have something to cling to and lean on the ice and get out of the hole.

Often in the spring it freezes well at night, so you should not leave a drill drilled deep into the ice overnight. An ice screw can become frozen into the ice so that you won’t be able to free it without an axe. If you are leaving an ice auger on a pond overnight, then the best way (and also safe from thieves, although I don’t remember such cases) is to tap the auger off the ice, wipe the blades with a rag or glove and lay it horizontally on the snow. If the blades are dry, then the ice drill can be hidden directly in the snow - nothing will be done to it.

Evgeny Korepin, Tomsk

Device and characteristics

The ice screw consists of the following parts:

• Handles. In a manual ice auger, they are placed on opposite sides of the central axis, or the upper handle is located strictly on this axis, forming a brace. Drilling is done with both hands, which allows you to evenly distribute the load.

• Auger – the spiral part of the tool, located below the handles, is designed to remove ice chips from the hole, determines the direction of rotation of the ice auger. It is connected to the brace with a connecting unit, which can be telescopic or removable. It is a rod with a welded spiral in the form of a metal strip.

• The cutting part is directly responsible for cutting into the ice. In most cases, it is a holder with two straight or rounded knives, or a monolithic cutting head. The shape determines the effectiveness of drilling holes in ice with specific characteristics. This is also affected by the angle of attack and tilt of the knives.

For electric and gasoline models, the handles are located directly on the frame with a drive, and are designed to fix the tool in a stationary position, preventing rotation opposite to the direction of drilling.

Material

In the production of ice tools, mainly cold rolled sheet steel or hardened steel with a high-quality coating is used.

There are titanium options, but along with the high strength and lightness of this material, which, due to the formation of an oxide film, is protected from corrosion, there are also disadvantages.

Among them are high cost, loud ringing noise when drilling, freezing of large amounts of ice in severe frost.

Iron is used less often because it is heavy.

The handles are covered with a material that should not crack upon impact.

Here the leader is hard rubber, which has a tactile sensation reminiscent of microporous rubber.

As for tool knives, they are made mainly from stainless alloy steel or tool steel.

Dimensions and weight of ice screws

The main dimensions of an ice auger are its length and the diameter of the auger.

The latter determines the diameter of the hole, and the first determines the drilling depth.

As for weight, on average it is about 2.5 - 3.5 kg.

The length in working position, as a rule, varies between 1.5 - 1.9 m.

This parameter can be increased by using a special extension, which is a rod 200 - 600 mm long, which is installed between the auger and the handles.

Auger sizes

The diameter of the auger is selected depending on the size of the fish:

- 90 – 100 mm – for sport fishing;

- 110 - 130 mm - for fishing with a balancer or jig;

- 150 mm – for fishing with girders;

- 180 – 250 mm – for catching large fish.

Making an annular ice drill

Most fishermen who prefer to use a ring ice auger to create holes prefer homemade tools, since they are extremely easy to make at home. The most important thing is to follow the pre-written instructions and also be careful when working.

Drawing

First, be sure to create drawings on which the work will be carried out. This will not only speed up the work process, but will also reduce the likelihood of errors in calculations to a minimum. It is important not only to draw the shape of the future drill, but also to indicate the dimensions of each side. Otherwise, even a couple of centimeters of discrepancy between parts in size can lead to a shift in the angle of the blade and incorrect operation of the drill.

Ring

The easiest way to make a ring for a drill is to use a piece of water pipe of the required diameter, cutting off a piece of suitable size from it. At the same time, it is not recommended to make the ring too high, otherwise it will be difficult to enter the ice. The optimal thickness is 17-20 millimeters, but the diameter should not exceed 190 millimeters - such a hole is enough to pull out almost any fish. Well, if you are lucky enough to catch a trophy specimen, you can always drill an additional hole next to the existing one.

Particular attention should be paid when making the cutting surface of the ring. The knife should be at an angle of 42-48 degrees (depending on preference). At the same time, it is initially made at an angle of 45 degrees, and only then it is sharpened with a grinder or receives a lining in the form of metal plates. The distance from the cutting edge to the bottom surface of the ring should be no more than 15 millimeters, but not less than 10 millimeters - otherwise the ring may not withstand the load.

Rotator rod

You can make a brace rod from almost any available tool, but we personally recommend using a 16 mm pipe for this purpose. To connect to the ring, it is best to install a metal rod, and then weld the pipe to the ring. This design is quite rigid, which guarantees its durability. It is recommended to treat the welding areas with a grinder to eliminate all irregularities.

Knife

You can make a cutting part for a ring ice ax using an ordinary kitchen knife or plane - purchased at any hardware store. To cut out a part of the optimal shape, you will first have to make a blank from thick cardboard (a slot is cut with a width equal to the diameter of the fastening bolts). After this, we apply the workpiece to the metal, trace the contours and, using a grinder, cut out the optimal part from an old knife or plane.

Handle and fungus

For ease of use, it is recommended to equip the ice drill handle with a special rubber bushing that fits onto a metal tube. Additionally, a thread made of anti-friction material (nylon) can be wound around the handle so that holes can be made even without gloves. Well, to prevent water from getting inside the pipe, a fungus is installed on top, cut from a wooden block exactly to the size of the pipe.

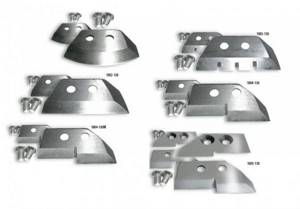

Types of knives for ice augers

Ice screws use 2 types of knives:

Flat

They are used mainly on domestic products.

Among the advantages are low cost, compactness, ease of replacement and the ability to sharpen at home.

Disadvantages: frequent chipping of corners.

Spherical

They are used in most cases on imported ice screws.

The advantages include quieter operation, smoother running, efficient drilling of wet ice and reaming out old holes.

Flat knives, in turn, according to the configuration of the cutting edge, are divided into:

- Straight – the edge is made in the form of a straight line;

- Rounded - the edge has a smooth rounding along its entire length;

- Serrated – straight edge with slots. The protruding parts form teeth.

- Stepped - steps made of two or three straight edges.

Instead of knives, some ice augers, particularly those from Rapala, use a removable spherical cutting head.

Homemade motorcycle ice drills

In addition to the ring ice drill, you can also make other simple devices at home using available materials and tools. Here are some successful examples:

- Ice auger-shovel. It is a brace with a pin, in the lower part of which there is a tip made in the shape of a spatula or spoon. With the help of such a drill, you can easily drill a hole, the depth of which is no more than 30 centimeters.

- Auger ice screw. It consists of a rod in the form of a pipe, as well as a special screw belt welded to the rod. The “blades” are made from ordinary metal rings, which are then bent at a certain angle.

- Electric ice axe. It is made from a ring ice ax and a screwdriver. The two instruments are connected using a special adapter. It is important that the engine power is at least 18 Volts, otherwise the ice auger will not last long.

- Motorized ice drill. This device is made from a chainsaw or trimmer (a device for cutting grass). It is very difficult to create a tool, but even if you do it, be prepared to catch unkind glances from other fishermen, since it will make a lot of noise.

Making an ice auger for winter fishing is not such a difficult task as it might initially seem. The most important thing is to create the correct drawings, as well as prepare suitable materials in advance. A home-made device for making holes will not only cost less, but will also cause envy among other fishermen.

Types of ice drills and their prices

According to the type of drive, the ice auger is:

• Manual – rotated by hand.

There are one-handed versions, where one of the handles is located on the same axis with the auger, and two-handed ones - with handles spaced on opposite sides of the axis.

The cost starts at 1500 rubles.

• Gasoline – driven by an internal combustion engine.

Among the advantages are the ability to drill large-diameter holes and operability at low temperatures.

The disadvantages of a motorized ice drill include noise, the presence of exhaust gases, and the need for fuel.

The motor of this fishing tool has handles attached on both sides, which act as a frame, and the auger is attached to the gearbox shaft.

The cost of good models complete with an auger ranges from 25 to 50 thousand rubles.

• Electric.

The auger is rotated by an electric motor powered by a battery.

Among the advantages of an electric ice drill are ease of operation and low noise level.

Compared to the previous option they have a low cost.

Most cordless ice augers are equipped with electrical cables for recharging the battery from a car cigarette lighter.

High-quality models will cost the buyer 18–30 thousand rubles.

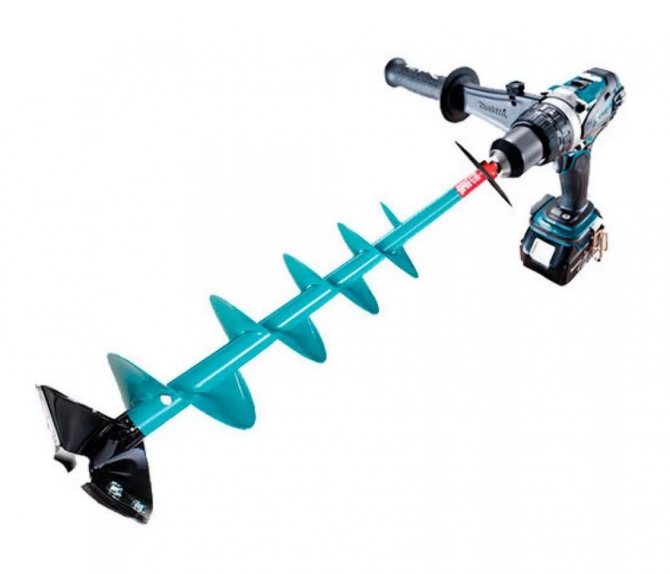

Electric models include a screw mounted with a special adapter in a screwdriver chuck.

Some manual options are initially suitable for use with a power tool, gasoline or electric motor.

A screwdriver for an ice drill must have a torque of 80 N/m and have a battery with a capacity of more than 2.5 Ah, where the voltage is at least 18 V.

According to the type of working part, the ice auger is:

• Screw – the most common option.

Structurally, it is a rod on which knives are attached in the lower part; there is a spiral metal tape around the entire length.

Available in diameters from 70 to 250 mm.

• Ice drill “cylinder” – used extremely rarely.

Another name is “cutter”, obtained due to the corresponding shape of the cutting edge.

In operation, a circular ice drill cuts a circular groove through the entire thickness of the ice.

The resulting ice cylinder is simply pushed under the ice.

• Ice drill “spoon” – the cutting part is made in the form of a tablespoon with a pointed edge.

This design is considered obsolete and is used extremely rarely, since an unreasonably large amount of effort is spent on the work.

Rotation is performed in any direction.

For ease of transportation of the ice drill, its length is expected to be reduced.

According to the design they are distinguished:

• Telescopic models – broken in half due to a special connection.

The length of the tool is reduced by almost half, depending on the length of the auger.

• Options with a removable handle, where the handle is removed accordingly.

According to their purpose, ice screws can be divided into:

• Models for dry ice – equipped with flat blades, which are ineffective on wet ice due to their frequent jamming.

• Models for wet ice – equipped mainly with spherical knives.

Such ice screws are often called universal, as they cope well with all types of ice.

Products equipped with replaceable knives allow you to adjust the angle of attack and tilt using washers and pads to achieve better performance.

Screwdriver and ice screw - how to connect them

When planning to make an ice auger from a screwdriver, a very pertinent question arises about how to connect these two devices. To ensure the transfer of torque from the screwdriver chuck to the ice drilling attachment, you will need to use a special adapter. This is a metal adapter that you can buy or make yourself. To make such an adapter, you need a cylindrical steel blank, the shank of which must be sharpened to a hexagon.

The size of the hexagon should be such that it fits inside the keyless chuck of the screwdriver. It is not recommended to use cylindrical shanks, since they can rotate in the chuck when the drill rotates.

This is interesting!

Many fishermen complain that the drill falls out of the chuck after making a hole in the ice.

To prevent this from happening, it is recommended to use a key chuck instead of a quick-release chuck, which is more reliable and effectively holds the nozzle shank. To connect the adapter to the ice auger, you need to use a threaded connector. A simple way to connect is to drill a hole with a diameter of 6-8 mm in the side of the nozzle and cut a thread. A bolt is screwed into this thread and serves as a clamp for the adapter inserted inside the ice auger. So, when all the nuances of constructing a nozzle for drilling ice for the appropriate tool have been identified, all that remains is to make it yourself.

Which ice screw to choose?

When choosing an ice drill, you should take into account its following characteristics:

- • Rod length (to handle) – determines the maximum thickness of ice that can be drilled. This figure can be increased by using extension cords.

- • Auger diameter – completely determines the diameter of drilling holes. Depends on the size of the fish for which the hole is drilled. The most common diameters are 110 – 130 mm.

- • Noise level during drilling. When fishing, sometimes this indicator is decisive, since excessive noise can simply scare away all the fish. Among hand-held ice augers, titanium models are considered the noisiest, producing a characteristic ringing sound. In addition, improperly sharpened knives can also make noise. Among all ice drills, the noisiest ones are gasoline models.

- • Availability of spare knives. When choosing an ice drill model, you need to make sure that the knives for it are on sale, and you won’t have to spend weeks searching for them. The fact is that knives are the first thing to fail. They get dull and break.

In addition, variants of a certain configuration are better suited to certain ice, which means that when fishing you must have at least one set of replacement knives with you.

- • Weight. Lightweight models are comfortable to carry, but their low weight makes drilling more difficult.

It should be noted that you can easily drill the ground with an ice drill if you install an auger appropriate for this task on it.

In order to expand the functionality of the device in this way, you should check in advance the availability of similar screws on sale for a specific product model.

Choosing a drill for winter fishing

If an angler expects to drill 2-3 holes in a whole day and passively sit on them waiting for a bite, then there is no particular need to purchase a high-quality tool. For fishermen who prefer to actively search for fish, a good fishing drill is one of the main components of successful fishing.

Fishing stores offer a wide range of drills, so it can be quite difficult for a novice ice fisherman to decide which ice drill to choose for winter fishing. First of all, you should decide on the choice of diameter. The most universal are products with a screw diameter of 130 mm. A fish of very respectable size can fit into a hole of this size, and the drilling process itself does not take much effort.

Sports fishermen, as a rule, catching small fish, use products with a diameter of 90 mm. Such a drill very quickly makes holes in ice of any thickness, which plays an important role when fishing for a while.

When fishing for pike perch and pike, it is preferable to use drills with a diameter of 150 mm. You can easily drag a trophy specimen into such a hole.

To catch such wide-bodied fish as bream, you will need an ice auger with a diameter of at least 200 mm. Drilling holes with such a tool is very difficult, but when fishing for bream, there is usually no need to make more than 10 holes.

Just a couple of decades ago, ice fishing enthusiasts had only mechanical (manual) rotators at their disposal. In recent years, the fishing industry has created units with different types of drive. Modern ice screws can be divided into several categories:

- manual,

- gasoline,

- electrical,

- drills with a screwdriver.

Hand rotators are invariably in demand among most fishermen because they are relatively inexpensive and, apart from regular replacement or sharpening of knives, do not require additional maintenance. The hand drill is lightweight, which allows the fisherman to actively move around the reservoir in search of fish. The most trusted products are from Scandinavian companies. The ice drill, which occupies a leading position in the rating of hand drills, has gained great popularity among domestic manufacturers.

When drilling holes in thick ice, you can use a gasoline ice drill for winter fishing. This tool requires constant monitoring not only of the sharpness of the knives, but also of the availability of fuel and the health of the engine. This category has several main disadvantages:

- high cost,

- high noise level when drilling,

- heavy weight.

In addition, when using such a device, the fisherman’s hands will constantly smell of gasoline. The smell of fuel can remain on the bait, which will negatively affect the fish bite.

Electric drills are inferior to gasoline drills in power, but have significantly less weight and operate very quietly. In order to use such a product throughout the day, you need to charge the battery well before fishing. The price of an electric rotator ranges from 60-80 thousand.

Russian craftsmen remake standard rotators and use a homemade adapter to attach a screwdriver to them.

In recent years, this design has become widespread. For stable operation of such a device, you will need a powerful screwdriver and one or two spare batteries.

What you need to know about ice screws?

Double-bladed ice screws are the most widely used.

Three knives are installed, as a rule, only on models whose auger is made of titanium, providing an easier move.

The other side of the coin is that three knives become clogged with ice crumbs faster.

The angle of attack is one of the most important characteristics of knives. The shallow angle is great for working on sticky wet ice.

Drilling takes longer, but is much easier.

Dry hard ice lends itself better to drilling with cutting elements with a larger angle.

The number of drilling revolutions in this case will be less, but physical effort will have to be made.

Consequently, the angle of attack for a layer of ice formed by severe frosts in a snowless winter increases slightly, and for a loose layer of ice in spring it decreases.

Alternatively, you can experimentally find the average angle, but there can be no universal solutions to “ice issues”.

In field conditions, when you need to drill one to three holes, it is enough to have a spare set of knives in case the main one breaks.

If you plan to drill a large number of holes, it is advisable to have a set of different types of blades with you, and then install the ones suitable for the operating conditions locally.

Ice drills can be used for drilling shallow holes in frozen ground, but one must understand that during such work the knives quickly become dull.

In general, the suitability of this tool for such work is questionable, since the main purpose is to break off pieces of ice that are denser than the soil.

For excavation work, specially designed drills or rotors are used.

What is a ring ice screw

Ring ice screws are currently losing their popularity. They are used mainly by older fishermen, as well as those who do not have enough money to purchase an electric drill. However, this does not mean that the ring ice auger is inferior in characteristics to its competitors. Yes, it requires some physical effort to operate, but it weighs almost nothing, and also has a simple design that can be easily made at home.

Principle of operation

The operating principle of a ring ice drill is based on the use of a ring, the outer diameter of which is 130 millimeters and the inner diameter is 80 millimeters. At the same time, during operation, the cutting edge selects ice only according to the shape of the outer ring, as a result of which a cylinder with a diameter of about 130 millimeters remains inside - such a hole is usually more than enough for successful underwater fishing.

Centering of the annular ice drill is carried out using a special triangular collar, which is located in the sole of the working part of the tool. Well, thanks to the eccentrically located drill handle, the load in the process of creating a hole is distributed evenly across both hands, as a result of which the fisherman hardly gets tired. Moreover, such a tool does not make noise, unlike the same motor drill.

Advantages and disadvantages

The ring ice auger, in comparison with modern motorized augers, has a fairly large list of positive aspects, which is why many fishermen still prefer it. Here is a list of just the main advantages that such a tool boasts:

- An even “glass” is drilled out, equal to the diameter of the ice drill ring. In this case, there is no need to destroy the cylinder during operation, which means that relatively little effort will be spent on creating the hole (unlike the same auger ice drill).

- There is no need to pump water after drilling a hole. After working with a motor drill or auger, the hole becomes clogged with crushed ice, as a result of which you have to “pump up” the water with a drill. With a ring tool, water immediately flows to the surface of the hole.

- Smooth edges of the hole. Due to the fact that the ring ice screw leaves behind a smooth hole, during fishing the fishing line will not cling to the edges of the hole. This means that the likelihood of gear breakage will be minimized.

- Ease of maintenance. All you need to do is sharpen the bottom edge of the knife from time to time. But motorized drills or electric drills are extremely difficult to maintain - they require regular lubrication, and also do not tolerate water getting into the engine.

However, ring ice drills also have some disadvantages. Not to say that they are critical, but it is precisely because of these points that many professional fishermen have abandoned the use of hand tools and switched to automation:

- hole drilling time is much longer than with tools with motors;

- the need for constant physical impact - the fisherman gets tired at least a little;

- difficulty at the beginning of drilling - it can be quite difficult to properly bury the knife into the ice.

However, ring ice screws are completely worth their cost, since their manufacture does not require the use of expensive materials or complex systems.

Rules for the operation and storage of ice augers

Proper operation of ice drills significantly extends their service life.

For proper operation of the tool, the following rules must be observed:

• After each fishing, all elements of the product should be thoroughly wiped of water, and the knives should be coated with a thin layer of machine oil.

• You can protect your knives from becoming dull during transportation by using a special cover.

• When drilling, you cannot hit the ice with an ice auger, as this leads to breakage and dulling of the knives.

• To warm knives, it is unacceptable to use an open flame, since fire changes the properties of the metal, which leads to rapid wear of the cutting elements.

• Sand contaminating the ice can damage both the knives themselves and the coating of the ice auger. To avoid the spread of corrosion to exposed areas of metal, all scratches after fishing are covered with paint.

• Using an ice auger to drill holes in the ground may cause it to break. For these purposes, products that will no longer be used for their intended purpose are better suited.

• A wet auger should not be placed in snow. It is preferable to leave it drilled into the ice to a depth of 10 cm. Otherwise, ice build-ups will form on the auger.

• Ice-covered knives should never be cleared of ice by blows, especially using metal objects such as a hammer. This is a direct way to break them.

• Drill elbows and all threaded connections must be lubricated periodically.

Before long-term storage, all elements of the ice drill are lubricated with machine oil, after which special protective caps are put on the knives.

Features of choice

Before buying this or that option, it is important to know some selection rules so that there are no problems with use and operation. Because not all models of screwdrivers are suitable for this task. Selection criteria include:

- Tool power. This is the main parameter that is important to pay attention to. The higher the score, the easier it will be for a person to cope with various tasks. It will break through even a thick layer of ice and overcome obstacles. It is always better to pay attention to branded and expensive tools; of course, you can take budget versions, but their functionality may disappoint.

- The second thing to pay attention to is torque. Here you can also follow the rule: the higher, the better. However, this also increases the cost; this should not be forgotten. The minimum indicator is 50-70 Nm. You can buy such models, but they can take a lot of time before a person gets the finished result. It is best to purchase models - 80-90 Nm. It is important to remember that the torque indicator is not achieved at the expense of the impact properties of the tool. Because this option is completely useless when drilling ice.

- It's also worth looking at the overall build quality. Everything must be tight and secure. It is recommended to pay attention to the materials used. After all, the product will be used in extreme conditions and severe frosts. It is desirable that there is high resistance to bad weather, otherwise the device will quickly break. You should always give preference to well-known brands, as they produce reliable and durable products that will last for years and have a long warranty.

- Availability of additional options. The handle with two supports has a positive effect on the ergonomics of the tool. Because the product will not jump out of your hands. All this ensures convenient use. Of course, you can buy products that are not equipped with this element. But drilling in this case will become inconvenient.

Rating of powerful screwdrivers for ice augers

Makita DDF481RTE

A high-quality option that is highly durable and reliable. The model belongs to the professional category. There is no point in buying a tool just for winter fishing, because it will take a long time to pay for itself.

A powerful brushless motor is installed inside, which effectively copes with the tasks. The maximum torque is 115 Nm, so the product is capable of creating holes in a short time.

There is a rubberized handle that guarantees comfort throughout the entire time of use. The case is protected from dust and moisture, so it is not afraid of any bad weather.

Sold at a price: from 26,800 rubles.

Makita DDF481RTE

Advantages:

- Good power indicator;

- Comfortable handle;

- Small sizes;

- Effective work;

- High torque.

Flaws:

- High price;

- There are only two speeds.

DeWALT DCD991X1

A high-quality model that is well-built and attractive in appearance. The design is widely popular in all areas, as it guarantees the owner high reliability over a long period.

Battery capacity – 9 Ah. The power of the product makes it possible to drill up to 100 holes with a thickness of 1 meter or more without any problems, which is a good indicator. The built-in LED flashlight allows you to drill even at night.

But it should be understood that such a model is designed for those who do not fish for fun. Because the cost of the tool is quite high for simple use. Another benefit is a long warranty.

Sold at a price: from 23,000 rubles.

DeWALT DCD991X1

Advantages:

- The engine is highly resistant to wear;

- The body is made of durable plastic;

- There are three speeds;

- The model is equipped with a bright LED flashlight;

- High reliability;

- There is a high-quality brake that is designed to instantly stop drilling.

Flaws:

- Price;

- Large mass.

Bosch GSR 18 VE-EC 0 L-BOXX

One of the best options that guarantees the user reliability for the entire period of use. The model is shockless, so drilling occurs without any difficulties. Torque – 75 Nm.

There is a reliable and efficient 18 V lithium-ion battery. In addition, the product is equipped with an additional handle, which provides additional comfort during operation. The case is made of durable and resistant to various influences of plastic.

The average cost is 17,500 rubles.

Bosch GSR 18 VE-EC 0 L-BOXX

Advantages:

- Reliable manufacturing;

- Strength indicators;

- Efficiency;

- Long service life;

- Quality work.

Flaws:

- Not found.