What is a fishing yawn?

A snapper is a tool used to safely remove a hook from the mouth of predatory fish. Its use allows you to avoid cuts on your hands and simplifies the handling of trophies caught from the water.

In appearance, a fish gapper is a large pin. To make such devices, spring wire (less commonly plastic) is used, with which the mouth of a predatory fish is fixed in an open state. Steel wire has a diameter of 3-5 mm.

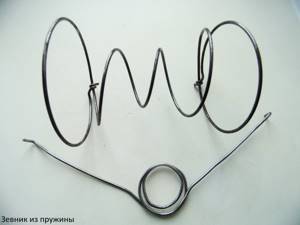

Photo: fishing yawn

Experienced fishermen know that such an accessory minimizes the likelihood of damaging your fingers on the hook and fish teeth.

Making a quality yawn with your own hands

The most common predator in our waters is pike. For large pike, a do-it-yourself yawner is made from wire with a diameter of at least 4 mm. The wire must contain alloyed elements. For small fish, devices made from elastic steel wire with a diameter of 2.5-3 mm, the length of the workpiece is 35-45 cm, have performed well. Below are examples of how to make a yoke for pike from a knitting needle or spring.

From a knitting needle

You will need one knitting needle made of alloy steel (you can take a bicycle one, but the quality will be worse). Visually divide the knitting needle in half, retreat 1.5-2 cm from the middle. Using pliers, bend the knitting needle around a metal rod or file handle with a diameter of 1.5-2 cm, make a full turn, bring the ends of the knitting needle so that an angle of 120° is obtained, compare ends. We retreat 4 cm from the edge and bend it at 45° in a plane perpendicular to the plane of the resulting spring. From the resulting bend in the same plane, bend the knitting needle in the opposite direction, retreating 1.5 cm, so that the total angle between the plane of the yoke and the transverse bar is 90°. We put on a heat-shrinkable tube (preferably a bright color) up to the spring coil and heat it with a hairdryer or gas burner. We do the same with the second arm of the device.

The corners of the cross bars should point in opposite directions. We make a clamp-bracket in the shape of the letter S from rigid wire for convenient transportation of the yawner. We bend one end of the staple around the arm of the device. If you bend the arms of the device in a vertical plane towards each other, then the clamping bracket is not required. The yawn will be fixed in the fastened position due to elasticity and transverse bars. In order not to lose a useful accessory, you can attach it to a flexible suspension.

From a spring

The main difficulty in making a gapper from a spring is that it is necessary to straighten the spring. To do this, use pliers to unbend the coils of the spring and beat them on the anvil. The goal is to get an equal straight workpiece. During manufacturing there should be no chips or cracks on the surface of the spring, otherwise it will burst during the process of repeated bending. We repeat all manipulations, as in the case of the knitting needle. There is a nuance: it is better to make not one, but two or three turns. It is better to re-wind a 2.5 mm thick spring onto a blank with a diameter of 1-1.5 cm.

Using a yawner when fishing for pike

The yawner is actively used by spinning anglers when fishing for pike: they squeeze it in their hand, insert it into the fish’s mouth, and then release it. Simply pull out the bait from the open jaws.

It is recommended to have this accessory with you when fishing from the coast and fishing from a boat. Many novice fishermen neglect this device, significantly complicating their lives.

About

Do it yourself

We'll look at how to make a pike yawn with your own hands in this section. A yawn can be made from a bicycle spoke. You can also use a piece of flat steel wire of a suitable diameter.

- You need to take a knitting needle or wire and, using pliers, make one and a half turns in the middle; you can use a screwdriver handle, a file handle, or another suitable object as a shape.

- The ends of the shed must be bent at right angles so that they look in different directions, then they must be processed with a file, removing the burrs.

- After this, you need to put rubber tubes on the ends of the wire so that the fisher does not injure the fish and does not scratch the bag or pocket and the things in them during transportation.

You can also make a wire brace that fits over the yawner to keep it folded when not in use. Thanks to this clip , the device will be more convenient to carry and transport.

A yawner cannot be called mandatory device, but fishing with it is much more convenient. Many beginning spinning players do not pay attention to this issue, but this is wrong. Every pike hunter should have a yawner in his arsenal . This device is inexpensive, and you can easily make it yourself. It does not take up much space, and you can always have it on hand when fishing. Using a yawner, it is easy to remove the bait from the pike’s mouth , while the likelihood of injury or damage to the fish’s mouth is minimized .

How to make a pike yawn with your own hands

To make your own yawner, a bicycle spoke or steel wire of the appropriate diameter (usually from 3 to 5 mm) is suitable.

You need to proceed as follows:

- Use pliers to form one and a half turns in the center, using the handle of a file or screwdriver to form the shape.

- Bend the ends of the product so that you get a right angle (they should look in opposite directions), process them with a file, remove burrs.

- Place rubber tubes on the ends of the wire so that the yawner does not cause harm to the fish and things in the angler’s backpack.

Using wire, you can also make a bracket that fits onto the accessory to hold it folded when it is not in use.

A yawn can also be made from a spring removed from a mattress, having first straightened it and then performed the same manipulations with it as with a knitting needle.

Manufacturing instructions

To make your own yawner, a bicycle spoke or steel wire of the appropriate diameter (usually from 3 to 5 mm) is suitable.

You need to proceed as follows:

- Use pliers to form one and a half turns in the center, using the handle of a file or screwdriver to form the shape.

- Bend the ends of the product so that you get a right angle (they should look in opposite directions), process them with a file, remove burrs.

- Place rubber tubes on the ends of the wire so that the yawner does not cause harm to the fish and things in the angler’s backpack.

You can also make a bracket from wire that fits onto the accessory to hold it folded when not in use.

A yawn can also be made from a spring removed from a mattress, having first straightened it and then performed the same manipulations with it as with a knitting needle.

DIY making

Many experienced fishermen prefer to make their own tools that meet their specific needs. Making a pike yawn with your own hands is quite simple. The most important thing is the choice of wire - it should not be too stiff, but at the same time have high elasticity, without bending from weak compression. To make relatively small yawns, ordinary bicycle spokes are often used. In addition to the material, you must have:

- Insulation from a wire corresponding to the diameter of the wire or suitable heat shrink tubing.

- An ordinary steel wire with a diameter of about 1.5 millimeters.

- A round rod or a fairly thick bolt, about 2-3 centimeters in diameter (you can use the handle of a screwdriver).

- Vise.

- Pliers.

- A lighter.

The manufacturing process itself is quite simple and accessible even to a teenager. Necessary:

- Clamp the end of the rod in a vice so that it is convenient to work with the remaining part.

- Place the middle of the wire on the rod and wrap it around it (the number of turns can be from one and a half to three and a half, depending on the hardness of the material). The last turn must be done so that the angle between the ends of the wire is about 40 degrees.

- Trim one of the ends of the future tool so that they become equal in length.

- Stepping back about 2 centimeters from the edge, bend the ends of the wire in different directions at an angle of 90 degrees so that they are strictly parallel to each other.

- Place 2-3 centimeters of heat-shrinkable tubing or plastic insulation from the wire onto the edges of the yawn.

- Using a lighter, heat the tubes so that they are tightly fixed to the wire. It is especially important to melt the ends so that the resulting tool does not injure the fish or scratch the tackle in the box.

- Cut a piece about 4 centimeters long from a thin wire.

- Form two hooks at the ends with a diameter approximately equal to the diameter of the knitting needle from which the shed is made.

- Throw one of the hooks over any of the arms of the resulting instrument and bend it into a full loop, thus obtaining a jumper for fixing the arms in the closed state.

Some anglers make two bends at the ends of the arms to position them opposite each other - first, at a distance of about 3.5 centimeters from the edge, an angle of about 120 degrees is formed, and at a distance of 1.5 centimeters from it another, about 45 degrees, directed towards the opposite side

At this point, the production of a homemade yawner can be considered complete. The main advantage of such gear is that it can be made in a convenient size and shape for the fisherman, suitable specifically for the size of the trophy he is targeting.

From a knitting needle

You will need one knitting needle made of alloy steel (you can take a bicycle one, but the quality will be worse). Visually divide the knitting needle in half, retreat 1.5-2 cm from the middle. Using pliers, bend the knitting needle around a metal rod or file handle with a diameter of 1.5-2 cm, make a full turn, bring the ends of the knitting needle so that an angle of 120° is obtained, compare ends. We retreat 4 cm from the edge and bend it at 45° in a plane perpendicular to the plane of the resulting spring. From the resulting bend in the same plane, bend the knitting needle in the opposite direction, retreating 1.5 cm, so that the total angle between the plane of the yoke and the transverse bar is 90°. We put on a heat-shrinkable tube (preferably a bright color) up to the spring coil and heat it with a hairdryer or gas burner. We do the same with the second arm of the device.

The corners of the cross bars should point in opposite directions. We make a clamp-bracket in the shape of the letter S from rigid wire for convenient transportation of the yawner. We bend one end of the staple around the arm of the device. If you bend the arms of the device in a vertical plane towards each other, then the clamping bracket is not required. The yawn will be fixed in the fastened position due to elasticity and transverse bars. In order not to lose a useful accessory, you can attach it to a flexible suspension.

From a spring

The main difficulty in making a gapper from a spring is that it is necessary to straighten the spring. To do this, use pliers to unbend the coils of the spring and beat them on the anvil. The goal is to get an equal straight workpiece. During manufacturing there should be no chips or cracks on the surface of the spring, otherwise it will burst during the process of repeated bending. We repeat all manipulations, as in the case of the knitting needle. There is a nuance: it is better to make not one, but two or three turns. It is better to re-wind a 2.5 mm thick spring onto a blank with a diameter of 1-1.5 cm.