Without batteries, many devices and mechanisms are not able to function. For example, in devices where electric current is used as the main energy carrier, special traction batteries are used.

If such a power source runs out, then the car will no longer be “push-started”, and the battery will need to be charged using a special device. This article will examine in detail the main types of traction sources of electricity, and also indicate the differences between various technologies for the production of such batteries.

What is a traction battery

Fundamentally, a traction battery does not differ from a conventional acid battery, but in order for the battery to obtain certain qualities, some changes are made to its design.

First of all, such products increase resistance to deep discharges. The number of charge/discharge cycles is also one of the most important characteristics.

To prevent the plates from crumbling and becoming covered with an oxide layer, the lead gratings are made thicker, and alloying elements are introduced into the metal alloy. The battery case is made of high-strength plastic, which also has minimal electrical conductivity values, which helps reduce battery self-discharge.

There are several main types of batteries of this type, so before purchasing a new battery, it is recommended that you familiarize yourself with the main characteristics of each of them.

Traction battery

Popular brands of traction batteries

The German manufacturer Sonnenschein has been in the market of autonomous power supplies for more than 100 years. The company's products use advanced developments in products designed to suit most of the needs of its customers.

Ventura offers more affordable but high-quality batteries. Reasonable prices are possible due to the location of production facilities in China. Nevertheless, the brand’s products are manufactured using AGM technology and are characterized by minimal evaporation and decent performance.

Types of traction batteries and their characteristics

Knowing the basic parameters of traction batteries is very important, because only in this case the product will be correctly selected, installed, and during operation consumers will not be connected to it in excess of the power limit calculated by the manufacturer.

The main batteries of this type are:

- Lead-acid. Cheap batteries that have the necessary qualities for use as traction batteries. The main disadvantage of such devices is their heavy weight.

- Nickel-cadmium. They have a long service life and are able to provide various self-propelled vehicles with electric current in the required volume. Ideal for forklifts, stackers and other warehouse equipment.

- Nickel metal hydride. High quality battery that can be used in a variety of tools and machines. Ideal for electric bicycles, wheelchairs and other low-power equipment.

- Lithium polymer. Modern devices in which there is no memory effect, and performance is maintained over a very wide temperature range. Due to its high cost, it is rarely used as a traction battery.

- Lithium iron phosphate. Ideal for electric motors of powerful cars and other types of equipment. They can also be used as the main electricity storage devices in a UPS.

- Lithium-ion. This type of modern traction batteries is the most common and is used as a battery for electric vehicles in uninterruptible power supply systems. Such electricity storage devices tolerate deep discharge well, have a long service life and can maintain voltage for a long time without loss.

Almost all of the listed battery models are effectively used as a source of electromotive force. The main criterion for selecting such products is the ability to withstand deep discharges and maintain electricity at rest. The possibility of using devices in high-power electrical engineering largely depends on these characteristics.

For loader

Dmitriy

It so happened that my echo sounder, with full illumination, consumes 1 amp hour, and in sunny weather, no matter how you look at it, in order to see everything well, you have to turn on the backlight to full. For ordinary fishing, you can take two 7 amp hour batteries with you and, in principle, they have tension enough for a day. But what about trips lasting 10 days or more? Where is it not possible to charge the battery? But Hidea9.9(15) has a lighting coil that, in principle, can charge the battery, so why not use it? Having studied the Internet in this area, I chose two options for myself: the first is to purchase a VRNL rectifier

this is what VRNL looks like

and this is how the Chinese rectifier is already on my engine

technically, it was more suitable for these conditions, but there is one drawback - its price tag. The second option is to turn to the Chinese for help! I found a rectifier on aliexpress that has almost the same function but is used in scooters, the price tag is 4-5 times less than on VRNL, but there is one drawback: the shunt circuit is used there. which means that when installing a rectifier, it will constantly load the lighting coil, regardless of whether the consumers are turned on or not. The scooter constantly has consumers of the same battery, which is always recharged when the engine is running + a headlight, which should always be on when the engine is running. After thinking a little about this topic, I came to the conclusion that it is best to use the Chinese version. When charging the battery, it will output voltage more correctly. When the battery is completely discharged, and as the battery charges, it will drop due to the shunt. Well, in order not to load the coil when it is not needed, you can simply install a button that will turn off the rectifier, and the coil will no longer be strained. On Ali I ordered a button for the motor and the rectifier itself. In total, everything turned out to be 4 times cheaper than the domestically produced VRNL. I assembled everything, even used the button backlight to work as an indication that charging is working.

True, I had to install a diode so that the indication would not light up from the battery.

But another drawback emerged: at idle and at low speeds there was not enough voltage for charging, but at full speed the batteries were charged quickly, you still had to save money. Over time, I also assembled a small electrical box for myself.

In which I placed two batteries, separating them with switches. That is, I installed two switches, with one I chose which battery would be charged, and with the second I chose which battery the echo sounder would be powered from. I installed a cigarette lighter socket, USB and a voltmeter with an ammeter in the box. Which I also bought from my Chinese brothers. My box has become more versatile; it has become possible to charge all sorts of gadgets such as cell phones, video cameras, and basically anything that can be connected via USB or a car cigarette lighter, as well as to organize LED lighting in a marquee or tent during evening gatherings on the road. I installed two batteries of 12 a/h and another one with a capacity of 9 a/h fit into the box, which was used as a reserve; it was not difficult to transfer the terminals to it. I have used all of this for more than one year and, in principle, everything is fine except for the lack of recharging at idle. But for us, large transitions were not uncommon, so everything was fine. The fact that I had to monitor the charge of the batteries and periodically switch them also didn’t bother me. but one day I came across a 23 ah battery and the idea was immediately born: why not build a new box on one battery? Yes, I will lose 1 a/h, but there will be no need for constant switching. Without thinking twice, I picked up a new box for the battery. By the way, a little about boxes, I tried a bunch of different tool boxes made of plastic, they all didn’t last long, then in a boat on a wave it will jump up and hit the duralumin slate and crack, then during transportation it will hit somewhere and something will fly off, then you’ll hit the latch with your foot and it will break until I come across this box

The small one fits perfectly into batteries with a capacity of 7-12Ah, and for 23Ah a slightly larger box is also ideal. I no longer installed an ammeter in the new box. I already knew how much it consumes, so I went by the principle of greater moisture protection of the devices, found a sealed voltmeter with a charge level indication, installed it in the same way as in the previous box, USB and a car cigarette lighter, and installed another voltmeter that will show how many volts are coming from the engine. The diode, which originally served to decouple the charging circuit from the battery, was moved from under the engine hood to a box and, due to it, the voltage from the batteries was not displayed on the second voltmeter.

But in the spring it wasn’t really possible to really test the new box; on the first trip to the water, the lighting coil that is located under the flywheel gave in to a long life! It seems that constant full-time work still affected her lifespan. Why not to the fullest because she always recharged a fairly drained battery while the other one was drained. But I’m an electromechanic, so why should I rewind the coil? There are almost any wires. And again, searching on the Internet, I found that these coils wind without problems, they use a wire with a diameter of 0.8 mm. I take off the flywheel on the engine, remove the coil and find that it is wound with 1mm wire. Now, what's the difference? A thicker wire will give more current, but the number of turns on which the voltage depends will go in less, and a thinner wire can be wound more, but the current will drop, but the voltage will rise! It turns out that the batteries will charge longer but in a more gentle mode and the voltage will rise at low speeds and, as a result, there will be a small recharge! And this is exactly what you need! A more capacious battery + charging at low speeds should provide me with an uninterrupted power supply throughout a trip of any duration, and now even while trolling while searching for active fish, the battery will be recharged a little! reeled it in and here is the first test in a barrel!

everything works charging at idle! This reel and box have already been tested on trips of 10 days on the Yumaguzinsky reservoir and 8 days on Irysh, everything works; the battery is enough for light in the tent and for the echo sounder and for charging gadgets. What else could you need?

What is the difference between a traction battery and a starter battery?

It is not always possible to use a traction battery instead of a starter battery. This limitation applies if the traction device is used for low-power devices, for example, for outboard motors.

More powerful 12 Volt devices, which can provide an electrical output of several hundred Amps, can be used to start car engines. Some differences are unique to certain types of batteries.

Gel. Gel traction batteries, unlike starter batteries, have lower discharge currents. For this reason, it is important not to confuse different models when purchasing a battery for a car with an internal combustion engine.

Traction products of this type are more resistant to deep discharge, but it is not recommended to consume 100% of it, even when using high-quality batteries.

Lead-acid. Batteries of this type can be used both as starter batteries and for permanent connection to powerful electricity consumers.

When used on electric forklifts and other equipment, lead batteries with a reinforced grid are used, to which alloying elements are added during production.

Lithium-ion. Lithium-ion batteries, due to their high price, are practically not used as starter batteries for cars, but there is no alternative to them for electric vehicles.

The products have a large safety margin, low self-discharge and no memory effect. Lithium-ion batteries installed on electric vehicles can provide a range of up to 400 km.

Boat

Using a car battery

Some novice fishermen install a car battery as a permanent power source for their electric boat motor. Experts do not recommend doing this for the following reasons:

- A car battery produces a high current when the engine starts, after which it is charged from the generator.

- Not all boat internal combustion engines have generators; they are installed only on powerful models. Therefore, after starting the engine, the battery may quickly discharge and it will no longer be possible to start it again.

- It is impossible to use the power source in question to constantly power the electric motor due to the fact that after 2-3 full discharges the battery completely fails.

We recommend: Parallel battery connection diagram

That is why it is recommended to choose boat batteries to start the internal combustion engine and provide long-term power to the electric motor. With proper maintenance they will last a long time.

Where are traction batteries used?

Traction batteries are used wherever it is necessary to ensure long-term operation of powerful electrical devices. Most often, such sources can be found in the following devices and mechanisms:

- Electric cars.

- Uninterruptible power supplies.

- Electric forklifts.

- Electric bicycles and scooters.

- Boats and boats with electric motors.

Depending on the voltage of the equipment’s on-board network and the electrical circuits of various devices, 12V and 24V products can be used. 48 Volt batteries can also be used to power powerful equipment.

Advantages and disadvantages of traction batteries

Traction batteries have both positive and negative qualities. The advantages of such energy sources include:

- Low self-discharge.

- Resistance to heavy and prolonged loads.

- A large number of charge/discharge cycles (Gel batteries are designed for 1200 such periods).

- Easy maintenance and storage.

- Russian-made batteries have quite acceptable price-quality ratios.

The disadvantages of such batteries include:

- Higher weight compared to other batteries.

- Low capacity recovery efficiency.

Despite the presence of some disadvantages, a worthy alternative to traction devices simply does not exist when it is necessary to ensure the operation of powerful electrical equipment that cannot be connected to a 220 or 380 Volt network.

For electric vehicle

Storage and operation rules

Activities carried out during operation are divided into three groups - daily, weekly and monthly:

- During operation, traction batteries must be fully charged daily after discharge, monitor the amount of electrolyte and, if necessary, add water.

- Once a week, the battery should be inspected for damage, cleaned of surface accumulations of dirt, and it is advisable to perform an equalizing charge.

- Once a month, it is necessary to check the performance of the charger, check the density of the electrolyte in all sections of the battery, and the voltage at the outputs.

The functioning of the traction battery directly depends on the electrolyte poured into it. Therefore, it is more preferable that filling with electrolyte is carried out under the manufacturer’s factory conditions.

Main conditions for proper storage:

- Storage premises must be dry, not freezing, and there should be no heat sources near the battery.

- During storage, do not allow self-discharge to exceed 80% (60% for GEL technology);

- Do not allow a completely discharged battery to remain idle for long periods of time.

- Fill only with distilled water (in no case with electrolyte or sulfuric acid).

- To avoid the appearance of condensation on the battery case, it is necessary to minimize fluctuations in temperature and humidity in the room where they are stored.

- Batteries are stored exclusively vertically, in one layer - it is strictly forbidden to put anything on top.

Important! The conditions for storage, operation and maintenance of traction batteries depend on the specific model, are determined by the manufacturer and are described in the relevant instructions.

Traction battery maintenance

Considering the fact that such batteries operate under very harsh conditions of electricity consumption, trouble-free operation can only be ensured if the battery is serviced on time.

First of all, traction batteries need periodic charging. This procedure should be performed using special chargers, and to ensure fire safety, the room must be equipped with a powerful ventilation system.

Monitoring the level and quality of the electrolyte is also the most important preventive measure for traction battery models. If there are deviations from the norm, the density of the electrically conductive composition is normalized or it is completely replaced.

What to look for when choosing a traction battery

When choosing a new traction-type battery, it is necessary to ensure that the battery is physically placed in a special compartment. Many car models have limited space for installing a battery, which must be taken into account first.

The power of the electricity source is also the most important parameter, therefore, when purchasing a new product, you should definitely select the battery by voltage (V) and capacity (Ah).

The optimal solution to the problem is to purchase a traction battery of the type recommended by the manufacturer of the devices where the battery is planned to be installed.

Features of LFP batteries for boat motors

We supply batteries for outboard motors in durable cases made of ABS plastic. Thanks to the use of a rubber gasket, they are sealed and waterproof. For convenient carrying of the battery, the protective boxes have a handle, and a valve to equalize the pressure. To track performance characteristics, the case may additionally have a display with a charge indicator.

For safe use, LiFePO4 traction batteries are equipped with an electronic control system - a BMS board. It maintains the operating parameters of the battery within acceptable limits, preventing overcharging, deep discharge, current overloads and other dangerous situations. In emergency situations, the BMS board breaks the connection with the external source - disconnects the batteries from power or load, preventing them from operating beyond permissible values.

How to choose a charger for traction batteries

The charger for traction batteries must ensure high-quality restoration of the battery charge. A conventional starter battery charger cannot always be used to charge traction batteries.

First of all, insufficient voltage may be generated in such a device. For example, to recharge many traction batteries, a voltage of 48v is required, which conventional devices are not able to provide.

The current power is also very important, because the traction battery can be used on a daily basis and to replenish electrical losses it is necessary to provide sufficiently high current levels.

The cross-section of the connected conductors will depend on this indicator, so wires with “crocodiles” from conventional charging also cannot be used to connect more powerful chargers to the battery.

It is recommended to buy a new charger only if the model is approved by the battery manufacturer.

Charge current and voltage

Charge voltage

Small 12 volt battery

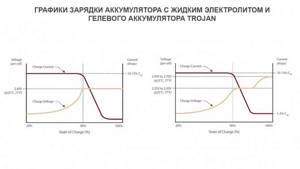

Thick plates of serviced traction batteries with liquid electrolyte allow an increased voltage of the second stage of charging - 14.8 V. For AGM, gel and maintenance-free batteries with liquid electrolyte this voltage is 14.4 - 14.7 V.

Charge charts for a battery with liquid electrolyte and a Trojan gel battery. Source https://www.trojanbattery.com/

Gel batteries are the most sensitive to increased voltage, so it is recommended to charge them in the range of 13.8 - 14.4 volts.

Charge voltage for Trojan and DEKA traction batteries

| Battery type | With liquid electrolyte | AGM | Gel | ||

| Brand | Trojan SCS 150 | DEKA DC 31 | Trojan 31-AGM | Trojan 31-GEl | DEKA 8G31 |

| Absorption voltage, V | 14,8 | 14,8 | 14,1-14,7 | 14,1-14,4 | 13,8-14,6 |

| Support voltage, V | 13,2 | 13,4 | 13,5 | 13,5 | 13,4-13,6 |

The charging voltage differs for different brands of batteries, so first of all follow the manufacturers' recommendations, and not the type of traction battery

Charge current

Depends on the type of battery and is determined as a percentage of the C20 capacity. The higher the current, the faster the charging, but the greater the danger of overheating and destroying the battery. Permissible maximum current for different types of traction batteries:

- Lithium batteries – 100% C20

- AGM batteries – 30-50% C20

- Gel – up to 30% C20

- Batteries with liquid electrolyte -10-25% C20,

Charge current for Trojan and DEKA traction batteries

| Battery type | With liquid electrolyte | AGM | Gel | ||

| Brand | Trojan SCS 150 | DEKA DC 31 | Trojan 31-AGM | Trojan 31-GEl | DEKA 8G31 |

| Charging current % C20 | 10-13 | 20 | 20 | 10-13 | 25-30 |

How to charge traction batteries

The process of charging electric vehicles is described in detail in the instructions for using such equipment. Fundamentally, this operation is no different from connecting a mobile phone to a network adapter.

Only the increased power consumption and temperature where the battery recovery process will be carried out should be taken into account. To ensure the necessary conditions, the room must be heated in winter.

Low temperatures negatively affect the electrical capacity of many traction battery models. You should also ensure a reliable power supply with wiring of the required cross-section.

Still have questions or have something to add? Then write to us about it in the comments, this will make the material more useful, complete and accurate.