What do we need for this?

- A set of screwdrivers, or replaceable bits (like mine);

- Lubricants: liquid (usually included with the reel, used mainly to lubricate bearings) and thick - for the main gears and the endless screw. (all this is on the diagram of your coil);

- 10mm wrench;

- Cotton swabs and cotton swabs - for wiping reel parts;

- Medical alcohol. I use alcohol because when it evaporates it does not emit harmful or foul-smelling substances, and if you do not take it orally, then there are no problems, alcohol washes away all sorts of contaminants no worse than solvents or gasoline;

- Medical syringe for 5-10 cc.

Rating of multiplier reels

To conclude the material, we will present a rating of the most popular cartoons that are popular among our domestic fishermen and have earned a reputation as reliable and easy-to-use devices.

Abu Garcia Ambassadeur BCX

Undoubtedly, the Swedish manufacturer Abu Garcia is considered the recognized world leader among cartoons. Among the brand’s huge offerings, we highlight the Abu Garcia Ambassadeur BCX casting model, which has become the leader in our rating.

Kosadaka Atlas

The second position belongs to the Asian representative Kosadaka with the Atlas power model, a universal tool for sea and freshwater fishing. A reliably fixed stepped clutch and a lightweight body contribute to comfortable trolling and, if necessary, throwing fishing.

Daiwa Steez

Among the ranking of the best multipliers, we bring to third position the Japanese brand, the famous Daiwa and its brainchild, the Steez model. An ideal soap dish for twitching and jig fishing with medium and light spinning rods.

Banax Zest

Fourth place goes to Banax with its Zest universal multi-purpose model. This mechanism for casting fishing with lures of 15–20 grams will become a reliable tool for beginners mastering multipliers. This product is budget-priced and of quite decent quality.

Before you start disassembling the coil, you need to remember a few nuances:

- Disassemble in a place where you can easily find small parts of the coil that accidentally fell;

- Lay out the removed parts in the order of disassembly, you can also photograph the entire process, so that if necessary, you can see how to correctly install certain parts of the coil. If there is a coil diagram, then even better;

- When wiping or cleaning parts of the reel with cotton swabs or swabs, you must ensure that no lint remains on the wiped surfaces;

- Too much lubricant is harmful; excess must be removed;

- The thread on the handle nut in a left-handed reel is left-handed, unscrews clockwise;

- For reel maintenance, special lubricants must be used that will not cause corrosion of the rubber and plastic parts of your reel.

How to use a baitcasting reel

One of the important advantages of a multiplier reel is the controlled delivery of bait of any weight or size into the fishing zone. But in order to make a competent cast, you need to adhere to certain rules or techniques developed as a result of the practical use of the multiplier. Let us present to the spinning angler a number of basic recommendations that help to correctly cast with tackle equipped with the type of fishing reel discussed in the article:

- the swing of the spinning rod should not be strong and sharp, so as not to impart excessive acceleration to the spool;

- casting is carried out smoothly, with an even supply of the form;

- when unwinding the cord, hold the spool with your finger, controlling the speed of its rotation;

- in order to make a long cast, the bait is lowered from the tip of the spinning rod by an amount of at least 40 cm, this accelerates the weight that regulates the braking system of the mechanism and at the same time tightens the line, eliminating overlap.

So let's begin

Unscrew the side cover screw, remove the side cover and take out the spool (photo 1).

We wipe the surface of the spool bearings and the side cover, lubricate it by adding a micro-drop of liquid oil. If necessary (whistle or rumble of bearings), remove the retaining ring of the side cover bearing and take out the bearing, having previously marked which side it was in the cover (photo 2), wash it in alcohol. Washing is best done by placing the removed bearing in a 5-10 cc syringe and drawing up and draining the alcohol with the syringe several dozen times; at this time the bearing will be washed. If such procedures do not help, then solving the whistling problem will require replacing the bearing. The same must be done with the spool bearing. Before removing, you also need to mark which side it stood on the spool axis. The only thing is that it is better not to try to remove the bearing without a special puller, as this can damage the pin in the spool axis and the spool itself, as well as cause scuffing on the spool axis. It is better to unwind the cord from the spool, put it in a bath of alcohol and, while twisting, rinse the bearing. After washing, let the alcohol dry and evaporate, then add a micro-drop of lubricant. Unscrew the screw of the decorative cap of the handle (photo 3).

Unscrew the nut with the left-hand thread and twist the friction brake adjuster from the axle (photo 4, 5).

Remove the ratchet with two thrust washers from the axle. Important (!) - the thrust washers should be positioned with their bulges outward and be slightly lubricated. Remove the axial brake cap, remembering how the ratchet parts are located (photo 6).

We unscrew the screws securing the power cover: two on the handle side and one on the spool side (photo 7, 8).

Remove the power cover and final drive gears (photo 9).

We clean the gears of old grease and wash them. Make sure that the metal discs that are inserted between the friction washers are free from scoring. If necessary, they must be polished - this affects the smooth operation of the friction brake. Remove grease on the friction brake washers and discs by washing them with alcohol. You also need to pay attention to the condition of the reverse stopper, clean it and lubricate it with liquid lubricant (photo 10).

We remove the line guide assembly (photo 11), for which we remove the lock washer (photo 12) and press on the worm screw shaft, it will rise, and a pin will come out of the groove of the line guide drive gear, which must be removed with tweezers (photo 13).

We remove the window of the line guide runner and the cap of the endless screw knife, the worm casing and the worm (photo 14).

At this point, in principle, further disassembly of the coil can be stopped. At least, I don’t see any point in further disassembly if there are no traces of contamination, unless the coil was in water and is not very dirty (photo 15). If you use your gear carefully, then you definitely won’t have such a need.

Next, we wash the parts of the units and, lubricating them, assemble the coil in the reverse order. We lubricate the main gear by applying a small amount of thick grease to the gear teeth with a spatula or screwdriver, turning the gears several times, removing the excess grease that has come out (photo 16, 17).

How often should a baitcasting reel be serviced? With intensive use - no more than once a season, but if the reel is used infrequently, then I believe that it goes without maintenance for at least 100 fishing trips. But if some incident happens while fishing: the reel gets into sand, dirty water, or something else, then you must immediately remove the reel from the rod and carry out maintenance as soon as possible. On the new generation Abu Garcia reels released in 2012, there is a technological hole for controlling the lubrication of the main gear, through which, if necessary, you can add lubricant without disassembling. As can be seen from the photo, we did not encounter any difficulties in disassembling and assembling the baitcasting reel; any fisherman, having the most minimal skills, can service his reel. The service described above took me about 30 minutes. Agree, there is not much to ensure trouble-free operation of the gear for the whole season. Good luck to you!

How does a baitcasting reel work and how does it work?

In comparison with inertia-free reels, we note the fact that multiplier reels have a simpler device, distinguished by some significant features that characterize the functionality of the device. The fishing line is laid on the multiplier drum using a worm gear. The main power load is transmitted to the spool drum, which has a cylindrical shape, due to a gear transmission with a special drive mechanism. Casting baits is ensured through various types of mechanisms, such as a braking system and can be designed according to the centrifugal and magnetic principles of operation, which are adjusted and adjusted in steps, and also eliminates the possibility of tangling the fishing line.

Brake system

In the majority, even budget baitcasting reels have a fairly serious braking system that regulates the casting of the bait, as well as protecting the cords from breaking, and the blank itself from breaking. The friction clutch ensures safe and reliable fishing. The friction brake system consists of a set of metal plates and fluoroplastic liners. Structurally, it is located on the handle and most often looks like a lever in the shape of an asterisk.

The main braking system is designed to control the decrease in the inertia of the drum during casting and splashdown of baits. This multiplier coil device can be made according to the principle of magnetic braking, centrifugal-mechanical braking, or a general combination of these operating principles. Magnetic braking is inherent in the device for working with small baits, and the centrifugal-mechanical and combined brake device will ensure high-quality fishing with medium and heavy simulators.

Handle location

For the convenience of fans of spinning fishing, manufacturers have mastered the production of multiplier reels for left and right hands. When purchasing a device, you should pay attention to this design feature of the product. After all, in practice, each spinning player has his own fishing characteristics. For example, when fishing with a spinning bait, which has already become a classic of the genre with a left-handed handle, switching to a reel will become more common with the selection of a similar, left-handed mechanism.

A right-handed multiplier reel is quite familiar to an angler who prefers an inertial action for a spinning set. Indeed, in the Neva and similar Soviet models of inertial reels, the handles on the drum were always located on the right side.

Coil power

The power of the device is determined by a number of characteristics of the mechanism, expressed not only in the size of the product, but also in some other important parameters. You can select a multiplier reel for a spinning rod for various purposes and its power according to the markings applied to the product body. Using the specified data, it is easy to determine the direction of the cartoon, which is expressed in the volume of the main cord placed on the drum, as well as the gear ratio of the device, which determines the ratio of the number of revolutions of the product handle to the number of revolutions of the drum collecting the cord.

Important! It is recommended to strictly adhere to the data indicating the thickness of the fishing line used for fishing.

Neglecting the recommendation risks tangling the line when casting and incorrect winding, which can lead to loss of tackle range and deformation of the line, leading to a decrease in its strength. The gear ratio indicates the power of the selected multiplier reel and the lower the value, the higher the traction force. Thus, a parameter less than the ratio to the gear ratio of 4.5 is considered to be a clearly expressed orientation of the mechanism towards a high-torque and powerful mechanism.

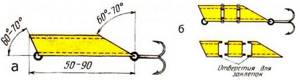

Features of the line layer

When choosing a multiplier reel, pay attention to the design of the line layer. In devices, this element can have either a wire plug or a ceramic eye. When planning a hunt for heavy and massive baits, the most suitable option is considered to be multis with a line guide in the form of ceramic eyes. And also for these types of structures it is recommended to use rigid, but at the same time more reliable braided lines as the main cords. In miniature soap dishes designed for delicate and sensitive wiring, manufacturers use line guides in the form of a wire fork in their designs. In such mechanisms, the requirements for the use of one or another type of cord are not so important and when fishing you can use both monofilament and small-diameter braid.

Since wire forks are much softer than ceramic line guides, you should constantly pay attention to their condition, excluding the appearance of nicks and other defects on the surface of the fork that could damage the cord. We also recommend applying backing made of medical plaster, with a rough structure, to the base of the drum when using wickerwork, which can often scroll during winding due to its smooth surface.