What is an extractor - design and types

An extractor is a useful tool that is designed to remove deformed threaded connections. Structurally, the tool is a bit or punch, which consists of two parts:

- Working - has a wedge-shaped thread, which is cut to the left (for fasteners with a left-hand thread, devices with a right-hand thread are used)

- Shank - hexagonal or tetrahedral shape, which is needed to connect an additional tool - a wrench, die holder or screwdriver

Manufacturers produce extractors of different sizes, which is important, since threaded connectors have different diameters. That is why extractors are sold in sets, which allows you to use a suitable attachment if necessary, when you need to unscrew a broken bolt. The most popular sizes of extractors are from M1 to M16.

The devices differ in design, and they are:

- Wedge-shaped - they have the shape of a cone without threaded edges.

The principle of their operation is that a hole is drilled in the stuck part of the bolt. The diameter of the drilled hole should be such that the extractor engages tightly with the stuck bolt. The nozzle is lightly driven into the drilled hole, and then the stuck bolt is unscrewed using a wrench. The tool is easy to use, but to achieve a positive result, you should drill a hole in the stuck bolt strictly in the center. Misalignment of the hole can cause the tool to break.

- Spiral or threaded - have wedge-shaped rods with threaded or spiral edges.

The difference between spiral and threaded ones lies in the reliability of engagement. The principle of operation of such devices is that a hole is first drilled in the stuck fastening joint, and then the extractor rod is screwed in a counterclockwise direction. After the rod is securely engaged, the stuck bolt is unscrewed. If a bolt with a left-hand thread is stuck, then it is necessary to use extractors with cutting edges in the right direction, that is, vice versa

- Rod - have a shortened shape of the working part, which consists of straight edges and with perpendicular slots.

Rod-type extractors resemble taps for cutting threads on nuts. The operating principle of such devices is also similar to taps. A core is used to make a mark in the center, after which the rod extractor is screwed in in a counterclockwise direction. As soon as the edges of the nozzle engage with the stuck bolt, jamming occurs and then it is unscrewed

The most popular are the spiral type models. For the manufacture of devices, high-strength alloy steel is used, which is why the cost of the tools is appropriate. Wedge-shaped extractors are the cheapest, but they are not effective in the following situations:

- When there is no space to drive a wedge into the hole

- When blows with a hammer can destroy the integrity of the entire device into which the broken bolt is screwed

Spiral devices eliminate the disadvantages of wedge-shaped extractors, however, to use them, a hole must first be drilled. If the broken bolt is in a hard-to-reach place and it is impossible to get to it with a drill, then rod extractors are used. Rod devices have hexagonal shanks for mounting in a drill or screwdriver chuck.

This is interesting!

It should be understood that extractors are used in the most extreme cases, when the head on the bolt is torn off flush. If the edges of the head are licked off, then you can unscrew the bolt using special clamping pliers - a hand vice.

Main types of extractors

Depending on the design and operational features, bolt removal is divided into several types and modifications. He can be:

- Wedge-shaped. The product has a faceted conical shape; during operation it is used as a wedge, which must be driven into an already prepared hole on the broken base of a stuck pin. After driving in and fixing the tool, it must be gradually turned out using a wrench. Using such an extractor is absolutely easy; the main thing to remember is that the hole that is drilled for it should be placed directly in the center of the base of the fastener. If this is not maintained, then the force applied during rotation will be displaced, which will not allow the broken element to be removed. Moreover, there is a possibility of breakdown of the device itself.

- Sterzhnev. It is a faceted rod and its operating principle is in many ways similar to a wedge-shaped tool. It should also be hammered into the drilled hole in the broken pin, wedged and unscrewed with a wrench. The main disadvantage of the rod device is the difficulty of removing it from the unscrewed part.

- Spiral-screw. It is the most common, convenient and effective device for unscrewing broken bolts. It also has a cone-shaped shape, only it already has a special left-handed or right-handed thread cut into it (for unscrewing left-handed threads). These types of extractors are not driven into the part, but are screwed into drilled holes in the fasteners, wedged and, together with the fasteners, are slowly removed. It is worth noting that when using it, a special wrench is required instead of a wrench.

What are extractors used for and what fasteners can be unscrewed with them?

The design of extractors is described in detail, but for what purposes can such cutting attachments be used? The devices in question are used for unscrewing any types of fastening connections - aluminum, steel, plastic, hardened and other types of bolts, self-tapping screws. It is very difficult to drill a hole in a hardened bolt, so to make the work easier, you should heat it and temper the metal.

Extractors are used to remove broken bolts from the following parts:

- From a car engine block - and this applies not only to outdated car brands, but also to modern foreign cars. When assembling a vehicle, defective parts are encountered, which are identified directly by the vehicle owners. When dismantling the engine block, a set of extractors will help you unscrew a bolt with a torn head.

- From the car hub - not all car models use nuts to tighten wheels, but also bolts. When tightening or unscrewing the bolts that secure the wheel, the cap can be torn off. This unpleasant situation can be solved by using extractors, without the need to replace the hub

- From the valve cover. Often the bolts remain in the valve covers and cylinder head, which can be removed using a set of extractors. Car owners are advised to acquire such an indispensable tool as extractors for unscrewing broken bolts

- From a concrete wall. You've probably encountered a situation where, when screwing a self-tapping screw or mounting bolt into a wall, it becomes deformed. Such malfunctions can be solved simply by using an appropriately sized extractor.

- Ignition switch in a car - when it becomes necessary to replace the ignition switch on a car along with the mounting frame in which it is installed, this is problematic. The steel frame of the ignition switch is secured with special disposable bolts (vandal-proof). To unscrew them, you will need to use extractors.

- Damage to the spark plug - when unscrewing, this part on the car can be damaged. Such cases, although rare, are quite appropriate. To unscrew the remainder of the broken spark plug, you should use an extractor. The task is complicated by the design of the engine, since on most modern cars the spark plugs are located in the shafts

- Small bolts - often when repairing phones, laptops and tablets, a problem arises when one of the remaining screws refuses to unscrew. It is impossible to find such a small extractor, since they are not produced. There are several current methods to solve the problem. The first is to use a thin drill bit. A through hole is drilled in the screw, after which the fastener can be removed. The second is to glue the screwdriver blade with epoxy glue, after which hardens, unscrew the fastener. In this case, it is imperative to use high-quality resin glue

Depending on the size of the fastening joints, it is necessary to select extractors of appropriate diameters. The price of extractors is affordable for everyone, but those who like to save money need to be careful, as cheap Chinese analogues are of unsatisfactory quality. Already the first time they are used, the threaded edges are licked off. The situation is even worse when part of the nozzle remains in the drilled hole of the remaining part of the bolt. In this case, the ability to unscrew the rest of the bolt becomes more difficult.

Everything about an extractor for fishing - how to choose or make it yourself

Almost every fisherman has encountered a problem when, when catching a fish, the hook sits very deep in the mouth of the prey. If the hook is very difficult to get, a special device called an extractor comes to the rescue.

Operating principle of the extractor

How to use the extractor?

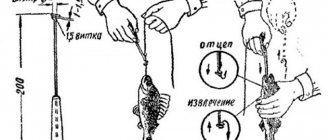

The principle of operation is to remove the hook from the fish’s mouth as quickly and easily as possible. If the extractor is made in the form of a needle, then at its end there is a special cutout, which must be pressed onto the shank of the hook, after which the hook will easily pop out.

If the tool is made in the form of tweezers, then you just need to hook the hook onto the fore-end and pull it forcefully in the opposite direction. To facilitate the process, donuts of this type have small notches; they allow you to improve the hook hook.

Types of extractor for fishing

- There are many different types of instruments of this type. If we consider the needle options, which are most often found among fishermen, they have a fairly stable principle of operation, it is also worth saying that the needle models are very durable, and with careful handling, they can last a single fishing season. Needle options are available in both plastic and metal versions.

Both options are quite good and reliable. The big advantage of needle models is their compactness and lightness. Such a unit can be put in any pocket, and it will not interfere with you when fishing. You can often see this device hanging around a fisherman’s neck. This solution is also very convenient; it allows you to quickly get the hook at any time.

- The second option is presented in the form of tweezers, which is also very convenient. The handles of these tweezers are rubberized, which allows you to work with the tool even if your hands are not very clean or dry. This model is made only of metal, which gives the tool very high strength and wear resistance.

You can often see such tweezers among spinning fishermen, since such an extractor is intended mainly for removing hooks from the mouth of predatory fish. It is worth noting that tongs are very convenient for removing both small and large spinning baits. When stored, they take up fairly little space; every fisherman can take them with him to a remote location.

Which extractor should I buy?

Now there are a large number of different options on the market. Everyone has both their pros and cons.

Extractor with Stonfo needle

This model is available in two versions. The only difference between them is size; the rest of the functionality looks exactly the same. The model is very durable, which makes it very popular among fishermen, both professionals and amateurs. A very important addition is the presence of a needle.

This needle is necessary in order to untangle the knots that often appear on the fishing line while fishing. This needle can also be used to clean the float rings. These models are used mainly by fishermen who catch peaceful fish.

The Extractor with a Stonfo needle is not very suitable for extracting spinners, so this model should be used exclusively for float or bottom fishing.

Extractor 24 LH from PRESTON

This model enjoys some success among fishermen. The 24 LH extractor from PRESTON is quite durable and reliable. It is also worth noting its compactness. It is very convenient to remove both short and long shank hooks. The price of such a tool is more than affordable.

Extractor SALMO 9604-009

This option is presented in the form of tongs. The length is 23 centimeters, which makes it very convenient and easy to work with such a tool. The handles are rubberized and also made in black. It is very popular among spinning fishermen, since the SALMO 9604-009 Extractor is very convenient for extracting spoons, while it is not possible to damage the bait.

All metal parts of the instrument are painted, this will help avoid corrosion in the future, since the instrument is constantly located in an environment with high humidity.

Making the simplest do-it-yourself fishing extractor

Unfortunately, not everyone has the opportunity to purchase this device. Especially for such people, there is an excellent way to make a homemade instrument, and the whole process is very easy, and even a child can make such a device, since there is nothing complicated about it. This method is also budget-friendly; you will spend no more than 50 rubles on it, or even less.

Homemade toothbrush extractor

This version of a homemade assistant will consist only of a toothbrush. I advise you to buy the cheapest toothbrush, since purchasing an expensive one will simply not be advisable.

Let's start with the fact that you need to saw off the bristles from the toothbrush along with the head, while you need to leave a fairly long leg on which the head with bristles was held, since the longer you leave the leg, the easier it will be for you to work with the tool, which is what actually comes from it required. Afterwards, you need to cut a little through the leg of the toothbrush; this cut will help you remove the hook from the fish’s mouth.

Next, sand off all the resulting burrs on the toothbrush, as they will greatly rub your fishing line in the future, and instead of benefiting, the homemade option will only bring harm. When making a cut, it is worth considering the diameter of the shank of the hook; it should slide freely into the resulting cut. It is also worth making a small hole at the top of the toothbrush.

This hole is designed to hang the extractor on your neck, which is very convenient for vigorous fishing. After the above manipulations, your tool is ready for use. I think if you do everything competently and carefully, you will get an excellent assistant.

Reviews and advice from fishermen

All experienced fishermen advise before purchasing a tool to pay close attention to ensure that the extractor is not a cheap fake, since such specimens are famous for their extremely short service life. It is also worth paying attention to the reliability of the part that pulls out the hook; it should be made of either metal or thick plastic.

Once you try an extractor while fishing, you will not be able to refuse it in the future, as it is very convenient and practical. You don’t have to worry about trying to get the hook out with your hands; it’s better to just buy an inexpensive extractor.

I caught this carp using a bite activator. Now I never return home without fish! The time has come for you to guarantee your catch!!! The best bite activator of the year! Made in Italy…

MORE →

bolshoyulov.ru

How to use extractors or a simple way to unscrew a damaged bolt

Knowing what types of devices in question there are, it remains to understand the question of how to use them correctly. The process of using different types of extractors to unscrew broken bolts has already been briefly described above. Below is a detailed step-by-step description of how to use the tool:

- Prepare the necessary tools and materials - punch, set of extractors, hammer, drill and metal drills

- Using a center punch and hammer, mark the center on the remaining part of the bolt. This point should be given special attention, since not only a positive result depends on it, but also the serviceability of the extractors used. In addition, if you incorrectly mark the center of a damaged bolt, the thread can be damaged during the drilling process.

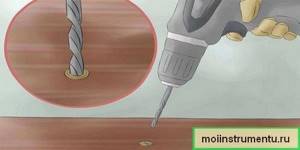

- After marking, you need to use a drill with a drill of the appropriate diameter. The choice of drill requires an appropriate approach. The drill must be smaller than the diameter of the bolt to avoid damaging the thread. It is recommended to start drilling with a small diameter drill

- The depth of the hole depends on the size of the thread. If the damaged bolt is short in length, then it is enough to drill 10-15 mm

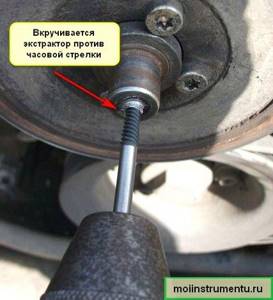

- An extractor is installed in the hole. This may be a wedge-shaped or spiral element. The wedge-shaped one is hammered into the hole until it stops, and the spiral one is slightly compacted in the hole with a hammer, and then screwed in with a knob or die holder. The nozzle must be rotated to the left or counterclockwise

- As soon as the nozzle goes all the way, it will begin to unscrew the remaining part of the mounting bolt. When rotating the attachment, make sure that it is parallel to the direction of the broken bolt.

- After unscrewing the broken part of the bolt, you need to fix it in a vice and unscrew the extractor in a clockwise direction

As you can see, this procedure is not difficult and does not require special skills, with the exception of special equipment. In addition, you can unscrew a broken bolt in this way if it is in a visible and accessible place. However, bolt heads often come off where they are difficult to reach, so it all depends on the situation. How broken bolts are unscrewed using extractors is shown in the video below.

Conventional twisting methods

All cases of breakage of fasteners can be divided into three types. It depends on them which tool and method of troubleshooting will be chosen. As a rule, bolts break:

- Protruding above the surface.

- Level with her.

- Deep inside.

In the first case, the problem of unscrewing is solved by using any clamping device: pliers, vices, clamps. The protruding piece is picked up and carefully turned out. If the protruding part is not long enough to hook, the end is sawed with a grinder or a hacksaw. It looks like a slot where a screwdriver is inserted, and the remainder is removed. For reliability, you can try to cut a cross-shaped slot.

Another method requires the use of a drill. The protruding fragment is cut off with a grinder, the surface is polished and a hole is marked in the middle using a core. A drill is selected and the broken bolts are drilled out to a depth of at least two diameters of the fastener. Using an old triangular file driven inside the hole, the broken bolt is unscrewed.

If none of the similar methods save the situation, you will have to turn to a special tool - an extractor.

Causes of bolt heads breaking

If you are faced with a situation where the head on a bolt is torn off, then the first question that arises is what to do? Few people are interested in why this happened; the main thing is to find a way out of this situation. How to unscrew a broken bolt with an extractor is described in detail above, so it is imperative to find out what causes such consequences. By knowing the reason, you can prevent such situations from occurring in the future. The reasons for breaking off bolt heads are as follows:

- Sticking - happens when the part experiences strong temperature loads

- Corrosion is the most common cause that has been combated for centuries. A rusty bolt is very difficult to unscrew, and almost impossible, depending on the degree of corrosion

- Low quality. Increasingly, low-quality products are found that deteriorate not when unscrewing, but even at the screwing stage. You need to beware of such products, otherwise you will need to use extractors often

- Wear - threaded connections experience various loads, including mechanical ones. For example, if you fasten a wheel on a car with one bolt, then the cap will break due to the impact of a heavy load.

- Rotation in the wrong direction to unscrew - standard fasteners are screwed to the right side and unscrewed to the left, but there are also non-standard devices. They have a reverse thread direction, which you need to know, otherwise an attempt to unscrew the bolt will result in licking the edges of the head or its breakage

- Incorrectly selected wrench - in this case, the edges are licked off rather than the head being torn off

Most of these causes can be eliminated. Make it a rule to lubricate all types of threaded connections with lubricants. This will eliminate the possibility of sticking and corrosion of connections. Never use low quality bolts, as today's savings will result in even greater costs tomorrow.

This is interesting!

In any case, no matter how it happens, if it turns out that when you unscrew the bolt, its head comes off, then do not rush into action. Consider your options carefully. What other methods are there for unscrewing broken fasteners are described below.

Other ways to unscrew broken bolts or how to do without an extractor

The method of extracting fasteners with a torn head using an extractor is the most reliable and effective, but its disadvantage is that not everyone has such tools. Of course, it is recommended to buy them and always have them in the garage, but if they are not there and you urgently need to unscrew a stuck bolt, then there are other ways to do this. Let's look at them in detail.

- How to unscrew a self-tapping screw with licked edges under a screwdriver - there are two ways.

The first method is to use thick fabric or rubber, which should be used as a spacer between the head and the screwdriver. Pressing the screwdriver tightly, you must try to unscrew the screw.

The second method is to use a mini grinder. With its help, you need to make a longitudinal groove on the surface of the head (cut a new edge for a screwdriver), and unscrew the fastener

- How to unscrew a screw with damaged edges on the head.

If the screw has a protruding head, then it is recommended to use special clamping pliers. This tool is also suitable for bolts that have licked edges. The cap is tightly fixed with pliers, after which the part is unscrewed

- If the cap on the fastener is torn off - when there are no extractors at hand, then you will need to use a welding machine.

Using welding, it is necessary to carefully grab the stuck part, and then unscrew it. This method was used before extractors appeared. If the size of the remaining part of the bolt allows you to drill two holes, then another method is used. Two holes are drilled into which two nails are inserted. Using pliers, you can unscrew the remaining part of the threaded element, but provided that the thread is not rusted

- If the cap is torn off, but part of the fastener protrudes.

In this case, you can use clamping pliers or a pin driver.

The decision to remove the remaining part of the threaded device must be made depending on the current situation. You should also know that there are no hopeless situations, and as a last resort, you can always drill out the remaining part of the broken fastener and cut a new thread. However, remember that this is the most extreme case.

Methods for unscrewing bolts, screws, screws with licked edges

If the usual method fails to unscrew the fasteners whose edges have licked off, you can use one of several proven options.

Gas key

This method is used when unscrewing bolts, since they have a protruding head that you can grab onto. For this:

- Clean the bolt head.

- Lubricate the joint with kerosene or diesel fuel, a liquid like WD-40 works well, and leave for 15–20 minutes.

- Unscrew the bolt. They do this with a gas wrench. With its help, a lot of force is created and it is possible to grip even a round head well.

The disadvantage of this method is that it is not always possible to get a gas wrench to the desired bolt.

Cutting new edges

If the bolt is large, then using a grinder you can cut new edges on it. It is enough to make only 4 of them and use a smaller key to unscrew the bolt. You can cut new edges on a bolt with a file, but this is more difficult and takes longer. You can make a cut on the head of a screw or screw using a hacksaw or grinder.

You can make a deeper cut on the head of a screw or screw for a screwdriver.

Hammer and chisel or impact screwdriver

This option is more suitable for licked nuts or fairly large screws. The chisel is pressed against the head of the fastening element and, hitting it with a hammer, the screw or nut is gradually turned. Small screws or screws can be removed using an impact driver and a hammer. After loosening the fastening, the work is done with a regular screwdriver.

An impact screwdriver can be used to unscrew small screws or screws with licked slots.

Band or piece of rubber

In this case, use a small part of a medical tourniquet or a piece of thick rubber. The selected material is placed on top of the head of the screw or screw, after which it is pressed with a screwdriver and gradually turned. The presence of rubber will help increase friction and solve the problem.

The harness is placed between the screwdriver and the head of the screw or screw.

Extractor

An extractor is a special tool that is used to unscrew screws, bolts or screws with licked or broken heads.

Extractor - a tool for unscrewing screws, bolts or screws with licked or broken heads

The order of its application:

- Using a thin drill, a small hole is made in the head. In some cases, the extractor can simply be driven into the licked screw slot.

- Select an extractor of the required diameter. Drive or screw it into the prepared hole. This depends on whether a regular or screw tool is used.

- Unscrew the bolt.

Video: unscrewing a licked screw using an extractor

Regular or left hand drill

Left-handed drills with counterclockwise rotation are available for sale. They improve tool centering and reduce the load on the drill, which gives higher productivity and drilling accuracy. By inserting such a tool into a drill, you can unscrew a screw or screw with a licked head. If you don’t have a left-handed drill, you can try to drill out the stuck fasteners using a regular one. In this case, you need to take a drill whose diameter is smaller than the diameter of the bolt or screw

You must act carefully so that you do not have to cut threads for new fasteners later.

The drill bit should have a diameter smaller than that of the problem bolt

Glue

A nut of the appropriate diameter is fixed to the head of the problematic screw or screw using epoxy glue or glue called “cold welding”. After the glue secures it securely, use a wrench to turn the nut and unscrew the screw or screw together with it.

Using glue, fix the nut to the licked head, and then unscrew the screw together with it.

Welding

If you have a welding machine nearby, you can fix a new nut on the head of a bolt or screw by welding it. After this you can immediately unscrew it.

A new nut can be welded to a problematic bolt or screw.

Solder and soldering iron

If you need to unscrew a small screw or cog, use a soldering iron and solder:

- Heated solder is dripped onto the head of the fastener with licked edges.

- While the tin has not hardened, insert a screwdriver into it and wait a few minutes.

- Unscrew the problematic screw and clean the solder tip of the screwdriver.

Useful recommendations from experts on how to unscrew a broken bolt

If an attempt to unscrew a threaded connection is unsuccessful, then there are some useful tips and recommendations from experts that will definitely be useful to anyone who is faced with such an unpleasant situation. These tips are as follows:

- To increase the efficiency of the actions carried out, it is necessary to heat the threaded connection

- Using a hammer and a punch set at a 45 degree angle will help remove the remaining part of the broken bolt.

- It is necessary to use lubricants, including WD-40 lubricant, to remove corrosion

Experts also recommend purchasing a set of extractors. They are sold in quantities of 4 or more nozzles of different sizes. Having the appropriate attachments available, you can always quickly remove the deformed part of the bolt. The video below shows why you should buy only high-quality extractors and avoid low-quality and cheap devices.