Experienced fishermen who use spoons (including homemade ones) to catch fish can talk about frequent cases of them breaking due to hooks. After all, as a rule, there is only one option in this case: grab the line as close to the spoon as possible and pull it until it comes off, which naturally leads to the loss of the spoon. And it can be very disappointing if the lost lure was made with your own hands at home and had good “catchability”. In order to reduce the percentage of lost spinners, you need to slightly improve their design as described and shown on the drawing of a homemade spinner below.

Read more about oscillating spoons at the link

There are several ways to make loaded spinners. The simplest is to add lead to the inside of the petal. But the spinner has an untidy appearance. It is better to cast spinners in special molds. For this purpose, gypsum, cement, graphite (the inner surface of the latter is metalized with copper), and metal forms are used.

Materials for making spinners

For the manufacture of spinners, sheet metal with a thickness of 0.5-3.5 mm is most often used.

The best metal for making spinners is copper and its alloys: brass, tempah (golden color) and cupronickel (silver-white color). Tombak and cupronickel are especially good.

In addition, a bimetal, which is soft iron coated with a layer of copper, or less often tin and zinc, can be successfully used.

Elastic grades of stainless steel are less suitable. Soft varieties are quite acceptable, but require processing. At an annealing temperature of 200-250° C, stainless steel acquires quite a variety of colors.

Aluminum and its alloys are unsuitable materials due to their lightness.

For casting spinners, it is most advantageous to use lead, adding tin or zinc to it if necessary. Lead is first poured into the mold, and then, when the lead has cooled, tin is poured, or vice versa. To increase the strength of the junction, the mold is additionally heated to the melting temperature of lead. Since lead spoons fade quickly, there are the following methods for finishing their surface.

The easiest way is to paint the lure “gold” or “silver” using the so-called “serebryanka”. There are sets on sale with varnish and bags of bronze or aluminum powder; After painting, it is advisable to sprinkle the spoon with mica crumbs.

Another method is galvanic tinning with the composition (in grams per liter of water): tin sulfate - 40-60 g/l, sulfuric acid - 45-90 g/l. First, tin sulfate is diluted in acidified water, and then the remaining acid is added. Treatment is carried out at room temperature of the solution. Power: coin cell or two coin cell batteries for flashlight; plus - tin plate, minus - bait.

There are other methods for finishing the surface of spinners.

Spinner thickness

The thickness of the spoon is closely related to its size and purpose. The thicker the spoon, the less mobile it is and vice versa. Thin spinners have easy mobility, while thick oscillating ones have good, stable movement.

The division of spinners into light, medium and heavy is determined by the degree of their mobility, depending on the thickness and regardless of their weight.

As a general rule, it is recommended to make spinners from thin sheet metal, ranging from 0.5 to 1.2 mm, and oscillating ones from thick metal, ranging from 1.2 to 3 mm.

As already mentioned, the thickness of the spoon is closely related to its size and stamping shape. Therefore, although changing the thickness is acceptable, it must be approached with great caution, since with a change in the thickness of the spoon, the nature of its play also changes.

It is not recommended to use spinners with a thickness of less than 0.5 mm, since very thin spinners, especially small ones, work unreliably and often “stick”, that is, they do not give play, and large and thin ones flutter a lot when casting. Likewise, small but thick spoons perform poorly, while large and thick ones will be too heavy to cast.

If it is necessary to have spinners weighing 40-45 g, their thickness should be in the range of 2.2-2.3 mm. It is best to take the thickness of the spinners according to a well-tested sample. If you have a good sample of a spoon and it is desirable to build the same spoon, but of a larger or smaller size, then their thickness should be taken in direct proportion to the area, i.e., how many times the area of one spoon is smaller than the other, the same number of times its thickness should be be smaller. In the case of using dissimilar materials, an amendment is made to the thickness of the spoon: by how many times the specific gravity of one metal is less than the other, the thickness of the spoon should be greater by the same amount and vice versa. If this rule is not followed, the spinners will differ in the degree of ease of their play.

Lure fishing

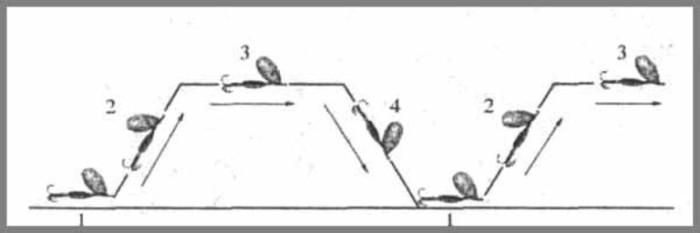

Using the sheer trolling technique is quite simple. The metal plate should reach the bottom surface, and the tip of the tackle, meanwhile, should make periodic short strokes.

After throwing the bait, you should observe a short pause (about 4 seconds). At the first bite, the spoon should lie on the surface of the bottom and, after a couple of seconds of calm, move slightly. Such behavior will only arouse the predator’s interest.

If the striped predator is sufficiently active, uniform wiring shows excellent results. To do this, after casting the bait, you should reel it in the opposite direction, maintaining a horizontal position. The speed of the retrieve directly depends on the fishing conditions.

With a relatively clean bottom surface, the game is played at an average pace, but in overgrown windows it is more advisable to reel in quickly.

The next most popular is the wiring called stop and go . This game is played in the style of reeling, alternating with minor stops. Another jerk - another stop. Frequent pauses contribute to disruption of the established course and provoke a chaotic fall of the bait to the bottom surface. This wiring will not leave any striped predator indifferent.

The procedure for making a homemade spinner with your own hands

From a large oscillating spoon, it is necessary to remove the winding ring connecting the spoon to the tee. Using a line of smaller diameter than the main line, tie the tee to the second winding ring. Attach the forend of the tee with soft copper wire (0.4-0.7 mm in diameter) to the spoon through the lower hole for the winding ring. Cut off the excess ends of the wire and separate them a little. The specified fastening will not affect the play of the spinner and will reliably ensure the integrity of the “tee-spoon” structure during casting and small efforts when hooking onto small and not very strong obstacles on the bottom, and at the same time, in the case of a “dead” hook, it will allow you to preserve the spinner, having lost only the tee.

You can read more about the equipment of spinners in the material “Equipment of scaffolds”

Recommendations for choosing the diameter of the main line and leader:

| Characteristic | Spinning reel type | Fish caught | ||

| pike | zander | perch | ||

| Line diameter, mm: main (leash) | Inertial Inertialess | 0,6-0,7 (0,5) 0,4-0,5 (0,35) | 0,5-0,6 (0,4) 0,4-0,5 (0,35) | 0,35-0,4 (0,3) 0,3-0,35 (0,25) |

| Lowest breaking load of fishing line, kg: | ||||

| basic (leash) | Inertial Inertialess | 10.5 (7.5) 5,3 (4,0) | 7,5 (5,3) 5,3 (4,0) | 4.0 (3.0) 3.0 (2.1) |

When using fishing lines and leashes according to this table, the safety margin of the main fishing line compared to the leash is on average 25-30%. This is quite enough to prevent the loss of the spinner when hooked, losing only the tee.

Homemade vibrator

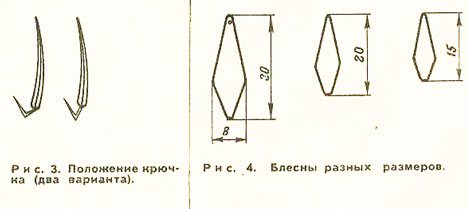

Oscillating spoons are considered very effective. This bait can be made in the following way:

- Mark the material according to the sketch. You need to get a diamond-shaped blank.

- Cut out the workpiece.

- Determine the minor axis and bend the part along this line.

- Solder a triangular metal plate to the part. The smaller it is, the better.

- Attach the hook to the plate, also by soldering.

- A ring will be fixed at the top to which the fishing line will be attached. First you need to make a hole for the ring.

- Sand and polish the bait to give it an attractive shine.

Homemade babbitt spinners

It is problematic to stamp spinning lures at home; for this, at a minimum, you will need a press. Cast lead spoons are less complicated to manufacture, but require galvanic coating with copper or other metal to create the necessary rigidity, which is also impossible without the appropriate equipment. In addition, such spinners are heavier than factory ones and therefore unsuitable for light spinning reels.

However, at home you can make simple cast homemade spoons from babbitt - an anti-friction alloy based on tin or lead, intended for use in sliding bearings. Babbitt spinners are cast in the same way as those made from lead, and the model is taken from a factory spinner or a plasticine imitation of any design. The mold for casting the spinner is made of gypsum (withstands up to 50 castings) or cement (M400-M600, withstands several hundred castings). The surface of the finished product requires only minor processing and sanding.

How to make a homemade spinner from babbitt

- Take (or glue) a cardboard box 6-7 cm high (the dimensions of the box should exceed the dimensions of the model by 1-2 cm).

- Fill the box halfway with a solution of gypsum or cement (the consistency of sour cream).

- Cover the model with a thin layer of Vaseline and carefully lower it into the solution so that it lies at the same distance from the edges of the box (in a factory lure, you must first cover the holes with plasticine). Lightly tap the box until the model is immersed in the solution to the desired depth.

- After the solution has partially hardened (25-35 minutes for gypsum and 24 hours for cement), remove any streaks of solution from the surface of the model.

- After complete hardening (after 2 hours for gypsum or 3 days for cement), grease the upper surface of the mold and model with a thin layer of Vaseline, then pour a new portion of the solution to the top of the box.

- After the solution has completely hardened, divide the mold, remove the model, and use a file to make a channel for casting (sprue) and air outlet in each half.

- Dry the mold well (7-10 days), otherwise during casting the process of vaporization and eruption of metal through the sprue may begin.

- Melt the babbitt in a container with a narrow “spout” (in an aluminum tablespoon), remove carbon deposits during the melting process and lighten the surface by periodically adding powdered ammonia. Try to avoid overburning the babbitt (pronounced blue color of the melt), which makes the product brittle. It is preferable to use Babbitt-83, which contains 83% pure tin, which does not tarnish and always has a silver tint.

- Pour the melt into the mold, shaking it slightly so that the babbitt spreads evenly, and remove the finished spoons after cooling. In the resulting castings, drill holes for the winding rings. Smooth out any unevenness on the cast spoon with sandpaper or a file.

Spoons made in this way usually do not require silvering, but if the homemade spoon is dark in color, it can be silvered.

You can get a silver spinner if you immediately pour melted babbitt into the mold. If you keep it on the fire a little longer, it will become golden in color, and the spinner will take on this shade. Keep it on the fire even longer and you will see the babbitt turn blue; the spinner will be of a bluish-olive tone. This type of lure does not require a sinker; it can be quietly cast “under the nose” of a perch or pike.

Posting spinners for perch

The simplest wiring, accessible to all beginners and experienced spinners, is to work with a reel normally. After casting, it is necessary to reel in the line at the same pace.

With such a simple game, you will be able to first examine the reservoir for the presence of snags and areas of vegetation invisible from the shore. In this case, you can quite count on a perch bite.

If a spinner is used, then in order for it to start working, it must be started.

If you simply reel in monotonously, the petal will remain motionless, and the bait will drag behind the fishing line, without attracting the attention of the fish.

To do this, you need to make several quick rotations of the reel, after which a slight vibration will be felt on the rod, indicating that the petal has wound up. After this, you can reduce the speed, making it minimal, but feeling the speed limit, below which the petal will stop.

Complex postings

Often it is complex wiring that forces the perch to rush to the spoon. They are quite difficult for beginning spinners, and at first bites are extremely rare. With experience, the play of the spinner in the hands of the fisherman acquires the necessary rhythm and bites become regular. There are different types of wiring:

wavy;- stepped;

- twitching.

Wave-like wiring is used when the perch is highly active. It is especially good if you manage to spot a place where a flock of striped predators is chasing fry.

Having cast there, you should reel in the line at an average speed, while either pulling it up or letting the rod go. As a result, the bait will swim in waves, changing the depth. The line should not weaken.

Such wiring is also possible using a slightly different technique, when the end of the blank moves left and right, causing the spinner to roll from side to side.

Stepped wiring involves changing the speed of rotation of the coil. The bait bounces up and smoothly sinks to the bottom, imitating the behavior of a fish looking for food. The perch usually grabs the spoon as it falls.

You should experiment with the speed of rotation and the number of revolutions per lift.

You can even work with a turntable this way. This will happen if the petal starts easily and only needs a few moments to start rotating again.

Flashing technique

Twitching resembles wave-like wiring, but the movement of the form is accompanied by periodic twitching. The jerks are made through a certain number of revolutions of the coil. In this case, you can use pauses. The repetition algorithm should be changed, achieving the most successful one on a particular body of water. You can do more pauses than jerks and vice versa.

Features of wiring in autumn

Autumn is the golden time for catching perch with a spoon. The fish is located mainly at the bottom at depth. And the easiest way to reach such conditions is with heavy spoons, because they sink well. Their weight and aerodynamics make it easy to throw far, where pits, edges and pits are usually located.

Most of all, spinners are ahead of other baits in terms of catchability starting in October.

In November, when the fish gather in large schools, moving along the bottom works very well. The rotation speed is a little slower than in summer.

Acceleration should be done only a few revolutions so that the spoon does not rise high. The cast is aimed at areas 5-10 m deep.

On small bodies of water, the wiring goes near the steep shore. At this time, the best bite is observed in cloudy weather without wind.

Oscillating spoon "Leningradka"

According to the dimensions indicated in the figure, cut a blank from sheet metal 3 mm thick, make two figured cutouts A and B with a depth of up to 4 mm in it. After this, stepping back 20 mm from the head part, use an emery wheel to grind the workpiece along its entire remaining surface so that its thickness towards the tail part reaches 1 mm. Next, bend the workpiece as shown in the figure, equip it with winding rings and a hook.

In addition to the holes in the head and tail parts, you need to punch a hole in the protrusion of the upper figured cutout (the diameter of all holes is 1.5-2 mm). It happens that it is useful to equip the spoon with an additional hook - then it is attached to the figured cutout.

For fishing at a depth of 1.5-2 m, the assembled weight of the spoon should not exceed 32-36 g.

Thanks to the bending of the spoon and the shift of the center of gravity to its head, the play of such a bait attracts a predator. If you attach red hairs to the tee and in the hole of the upper figured cutout, they prevent the spoon from quickly sinking to the bottom, which allows you to move the spoon slowly at the desired depth.

Spinner-spoon

Very often this spoon is used when fishing for perch and you can easily make it yourself. Below we will similarly explain how to make a lure for perch with your own hands:

- Take thin sheet metal, steel will do just fine, if not, then you can take an ordinary tin can from any drink. Cut a square sheet with metal scissors and straighten it, this will make it easier to draw the contours of the bait.

- Our bait will be in the shape of a diamond, use a permanent marker to mark the dimensions on the sheet.

- Using metal scissors, cut out the prepared layout.

- Calculate where the minor axis is located, along it you need to bend the metal gradually giving the shape of the bait.

- After giving the workpiece a shape, you need to solder a small triangle of copper, this can be done using a soldering iron.

- Then the hook is soldered to the copper plate.

- You will need to secure a ring at the top of the triangle; it is necessary for attaching the fishing line. To do this, drill a hole, it is advisable to wet the drilling site, otherwise you may damage the drill or part.

- Finally, we need to sand our vibrator and then it will be ready for use. Below you can see photos of do-it-yourself spinners.

Read here Fishing boat - principles of use and secrets of catchability. Essence, effectiveness and features of use (125 photos)

Good homemade spoon

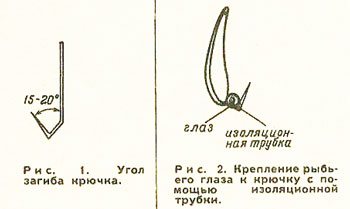

V. Sadikov offered the following homemade spoon. What’s new about it is not so much the lure as the hook (it’s homemade, there are no such things on sale). It is made from a needle or steel wire.

A hook of this configuration (Fig. 1) is unnoticeable and tenacious. The spoon is easily grabbed by fish. Placed on a hook and pressed with an insulating tube (Fig. 2), the fish eye film is hardly noticeable and does not interfere with the play of the spinner. The hook is bent immediately from the end of the spoon or released 2-4 millimeters. The neck with the sting is retracted at an angle of 15-20 degrees. The back of the hook also has a characteristic shape (Fig. 3). For a large spoon, you can also use a factory hook with a barb, after first releasing it on the fire and giving it the desired shape.

All sizes of the spoon decrease in proportion to its length.

Hooks for such spinners are made from sewing needles. They can withstand large fish, do not bend or break, are unnoticeable, very sharp, and make it easy to remove fish, which is important in the cold.

To make such hooks, you need to have steel sewing needles of different numbers:

- for small perch, roach, grayling - No. 3-4, sometimes even No. 2;

- for large fish (whitefish, large perch, ide, etc.) - No. 5-6.

The needles must be driven, their length does not matter. Hooks are made using small pliers, one of the planes of which is rounded by 2-3 mm. A special bend made from the eye of a thick needle driven into a wooden handle is also suitable for this. Anneal the needles in the flame of a match or candle. Start annealing near the thick end of the needle and observe the color of the tarnish. Stop annealing when the blue stripe that appears when heated approaches the thin tip of the needle.

After this, the tip of the needle is clamped with tweezers to the required length of the sting and bent around their flat antennae. Using the rounded side of the tweezers, the fore-end is slightly bent and a hook blank is obtained. Then, along the required length of the hook, a hook ring is bent around the rounded tendril of the tweezers, which should be perpendicular to its plane. The hem is first made in the direction opposite to the future ring, and then it is completely bent around it.

It is very important to configure the hook exactly as shown in the picture, otherwise it will not work well. These hooks must be tied with the point up, so that the fishing line is located at a right angle to the hook.

Non-snagging lure

For fishing in reservoirs with a large number of snags and grass, you need to use non-snag hooks. They usually do not cling to obstacles, so they do not break off.

How to make antiseptic with your own hands: the best instructions for making antiseptic at home + photo reviews

DIY medical mask - TOP 100 photos and step-by-step instructions with diagrams of the best ways to create

- How to embroider icons with beads - a review of the best ideas with photos and examples from masters

Made this way:

- Solder the hook to the lure. Use any suitable hook to suit your needs.

- Attach the antennae inside the spoon so that they cover the sharp parts of the hook.

- Solder the workpiece to the wire.

You can make your own antennae from springy wire or purchase ready-made ones. They will protect the tip of the hook, preventing snagging.

Drawing of a homemade spinner “Norway”