What does a leash consist of?

First, make sure that this seemingly insignificant piece of thread at the end of the rod is necessary. Then learn how to make your own fishing leash so you don't have to spend money on one.

This element performs three functions:

- Disguise of working line. Some peaceful fish - crucian carp, bream - are so suspicious that they do not take even the most tempting live bait when they notice a hook or braid. For timid bottom dwellers, homemade leashes are made from thinner threads than the main thread.

- Equipment protection. A hook in the water often gets caught on snags and debris. The gear, and often the rod, is at risk. If a thin piece comes off, it will not cause much damage to the equipment.

- Bait protection. This applies to large predators (pike, catfish). Having grabbed the bait, a strong fish will leave with a thin piece of fishing line and a hook in its mouth. She will not be able to survive, which is inhumane. For powerful fish, hunters prepare expensive bait and accessories made of durable material.

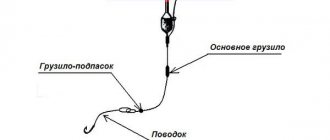

The leash consists of a piece of fishing line. Its other components: crimp tubes, swivel, carabiner.

The thickness of the product depends on the object of hunting, the length can be 15-25 or 30-50 cm. In feeder fishing, the size of the leashes is higher, and in strong currents they are 1.5-2.0 meters.

If you understand the purpose of this component of equipment, learn how to correctly manipulate its working properties, material and geometric dimensions, hunting will become more effective.

DIY nichrome leash

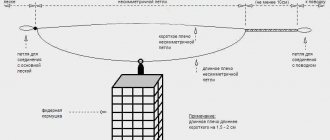

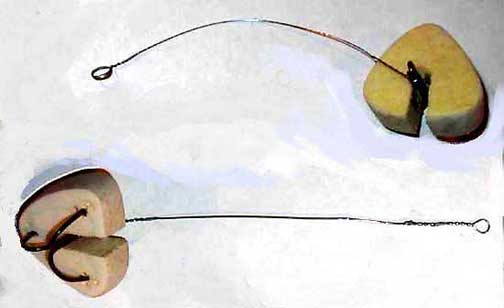

Self-made metal leashes of the girders are shown in the picture. Fishing devices are used to equip live bait gear for pike fishing throughout the year.

The nichrome leashes made of flexible links shown in the photo are more suitable for catching pike with winter and summer baits. Your homemade leash equipment may be different, more suitable for your gear. Moreover, you can make leashes with your own hands not only for equipping rigs, but also for spinning lures.

The page lays out the technical processes for making metal leashes for girders with your own hands from scratch. You can twist the leashes, either from a single wire or consisting of individual short nichrome links.

Also used on girders as leashes for catching pike and pike perch are mono fishing lines tied in pairs. Material about these fishing gear is printed on the next page of the topic.

Nichrome wire for making a leash

On my winter fishing poles for catching pike in snags there are metal leashes twisted with my own hands from nichrome wire. It is hardly possible to select a better non-scarce stainless material than nichrome for these purposes.

A rather soft wire drawn from nichrome has been preserved since the times of stagnation and was once borrowed (without return) from the native plant. Nichrome wire of different thicknesses is used for winding heating elements, devices for cutting foam plastic, soldering irons, antique tiles, and irons.

First, let's make with our own hands strong and stiffer leashes from solid nichrome wire for pike fishing poles. If you don't have nichrome wire material, anneal store-bought steel guitar strings. Or straighten the purchased nichrome spiral of the heating element.

What should a good leash look like?

This piece of equipment cannot be good or bad. It is suitable for certain hunting conditions, which may change during fishing. A good leash is one that will work in the given situation.

DIY fishing knot

An experienced fisherman will take with him a set of different fishing gear. In cold water, bottom inhabitants are not active: approach them delicately, offering a thin, barely noticeable tool. On a reservoir with a complex bottom structure, when casting from the shore, use stronger material, as there is a high probability of snags.

Your question to an expert

Leonid Grachev

Fisherman with a lot of knowledge and experience

Ask a Question

Choosing fishing line, hook and leash length

Each element of the leash equipment requires a careful approach. You will make a mistake if you make tackle from the main working line of the fishing rod and select a hook according to the diameter of the leader.

fishing line

Leading scaffolding differs from the main thread in the following parameters:

- wear resistance;

- tensile strength;

- permissible stretch.

The line is required to be resistant to fishing line knots. Optimal diameters are 0.1-0.16 mm. Place a feeder in front of the thinnest possible leashes: an elastic band 5-12 cm long will save the tackle in critical cases.

Checking line parameters

In the store, leader lines are sold in 50 m reels. Make sure of the quality of the material:

- Pay attention to the price, giving preference to products that are not too cheap.

- Refer to the breaking loads specified by the manufacturer. Reduce 30-50% of the parameter - this will be the actual breaking load.

- With a slight jerk to the sides, check the thread for break: if it breaks, it means it will not withstand the pressure of a one and a half kilogram individual.

- Pass the fishing line between your fingers, squeezing them tightly: if it gets twisted, refuse to buy it.

The texture will also tell you about a good product: a high-quality leading thread should shine.

Hook

In finished products, the hooks are guaranteed to be firmly attached to the leash. But if necessary, they can be replaced. The lead hook must be sharpened and hardened as much as possible, made of high-quality steel that can withstand long-term resistance from strong fish.

The forend of leash hooks comes in three types:

- long - for live bait;

- short – for bait of plant origin (corn, wheat);

- with notches - for an animal attachment so that it does not slip.

An experienced fisherman will have all types of hooks in his arsenal.

Leash length

Focus on the fishing object:

- A leash length of 20-25 cm is sufficient for roaches.

- If you are going for bream or bleak, take a short piece of equipment, 10-15 cm.

The choice of tackle depends on the type of fishing rod: for Bolognese and match fishing rods, the required length is 25-40 cm.

Winter wire leash

You can see durable leashes made of nichrome wire for winter harnesses in the photo. These same fishing devices can be used on many summer live bait gear for pike fishing.

At the end of each wire leash in the picture you can see wide twists of double or triple soldered rings that prevent the line from being cut at the point of attachment with the winter line equipment.

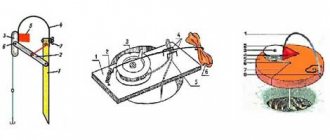

To make a metal leash for a winter harness with my own hands, I first bend nichrome wire 0.3-0.5 mm thick around a nail with a diameter of 3-4 mm. The distance from the end to the bend of the wire (20-25 mm) depends on the length of the twist.

Length of cable twist

Then, without removing the nail, I insert a tee or double into the resulting bend and twist together the short end of the wire and the nichrome leash itself to a length of 12-15 mm.

I cut off the excess wire at the end of the twist with side cutters and remove the nail. As a result, the hook will be securely fixed in the wire ring, and the homemade metal leash of the winter rope will be half ready.

(Spinning anglers, instead of a tee, can insert a swivel or spinner loop into the ring of a future homemade nichrome leash, then twist the wire using the proposed method.)

Next, I cut the wire to the required length of the leash, perform the same actions with its opposite end, only instead of a hook for equipping a winter girdle, I put a swivel.

Or I simply make 2-3 turns around the nail and twist the short end of the nichrome wire around the lead in the same way as in the method proposed above.

I cut off the excess wire, after which one homemade metal leash for the winter harness can be considered completely ready.

The length of my nichrome wire leashes is 10-12 centimeters.

Ring on a wire leash for attaching fishing line

A soldered metal ring made of double (triple) nichrome wire, thicker than the wire leash itself, will not allow the fishing line on the girder to be cut when fishing for pike or pike perch.

The rings, intended for attaching the fishing line of a winter or summer fishing rod for pike fishing, on the ends of the metal leashes are clearly visible in the photograph under the title of the article.

If you wish, a swivel can be built into the twist instead of a wire ring for attaching the fishing line. In addition, to connect the nichrome leash to the winter fishing line, you can use fasteners, winding spinning rings, etc.

Soldering twisted wire leash

Next comes the soldering of all the twisted surfaces of the homemade metal leash using soldering acid, although the twisting strength of the nichrome wire is such that even without soldering on the wire it will withstand quite noticeable jerks from the pike.

If, when making nichrome leads with your own hands, you are not going to solder them, then it is better to increase the length of the wire twist to 20 mm. But at the same time, it should be remembered that the most “rotten” place not only of a homemade nichrome, but of any wire is located at the point where the ring transitions into a twist.

Therefore, when starting to twist wire next to the ring of any metal leash for a winter harness, you should maintain a minimum spiral pitch. Towards the end it can be increased. To put it another way: near the ring, the twist of the nichrome wire should look more stretched.

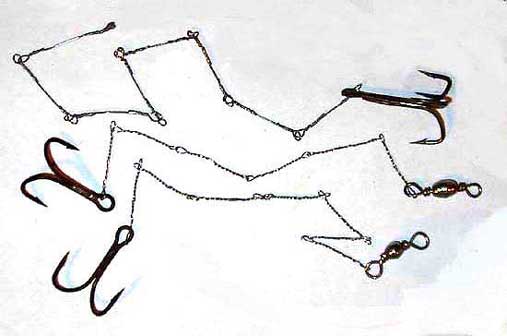

Flexible metal leashes made of links

We began equipping vents with flexible homemade metal leashes made from links long before the end of the last century. Although the definition of “flexible” does not quite fit such leashes. It is better to call them hinged.

Compared to the rigid wire leads discussed in the previous article, flexible leads are movable, consisting of individual metal links. The length of each link on my homemade nichrome leashes is 20-25mm.

The picture shows an example of equipping the fishing line of a spinning rod with a flexible metal leash consisting of links, where a standard swivel built into the last twist of the nichrome wire is used to attach the equipment to the fishing line.

The leash is removable and, to be honest, to demonstrate the photo on the site, it was removed from the equipment of one of the winter girders.

And further. Don’t believe that pike are so picky about leashes made for winter and summer fishing rods. The main thing is that the material (metal) of a homemade or purchased leash does not hinder the mobility of live bait.

Making a flexible metal leash

Flexible metal leashes for fishing rods and spinning rods can be made with your own hands as follows.

First, individual short links of a metal leash are twisted from nichrome wire using the manufacturing technology discussed above.

Then the end of the wire is inserted into one of the rings of the finished link, which is twisted around the nail. The same actions are performed with the other end of the short piece of wire and the second manufactured link.

As a result: we will get a homemade flexible metal leash, consisting of 3 links, the connections of which can be increased in a similar way to infinity. This is followed by careful soldering of the nichrome wire twists.

At the end of the last links of the manufactured flexible metal leashes, you can insert a loop or ring of any fishing device before twisting. This could be a swivel, a tee or a loop of a permanent spinner.

Above, the test examined the connections of homemade nichrome leashes with metal elements of various equipment intended for pike fishing. But it’s not for nothing that at the ends of some leashes we made double and triple twists of the wire, preventing the fishing line from being cut.